Preparation method and gas separation application of copper-based microporous metal organic framework material

A metal-organic framework and organic ligand technology are applied in the field of preparation of copper-based microporous metal-organic framework materials to achieve the effects of strengthening force and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1: Weigh 10mg of 3-hydroxyisonicotinic acid organic ligand, 45mg of anhydrous copper acetate, dissolve in 15mL of N,N-dimethylformamide (DMF) and 1mL of water. After sonicating and obtaining a homogeneous solution, it was then transferred into a 20mL glass reaction bottle, and subjected to a constant temperature reaction at 90°C for 96h to obtain the Cu-MOF crystalline sample with a yield of 60% (calculated based on the metal salt).

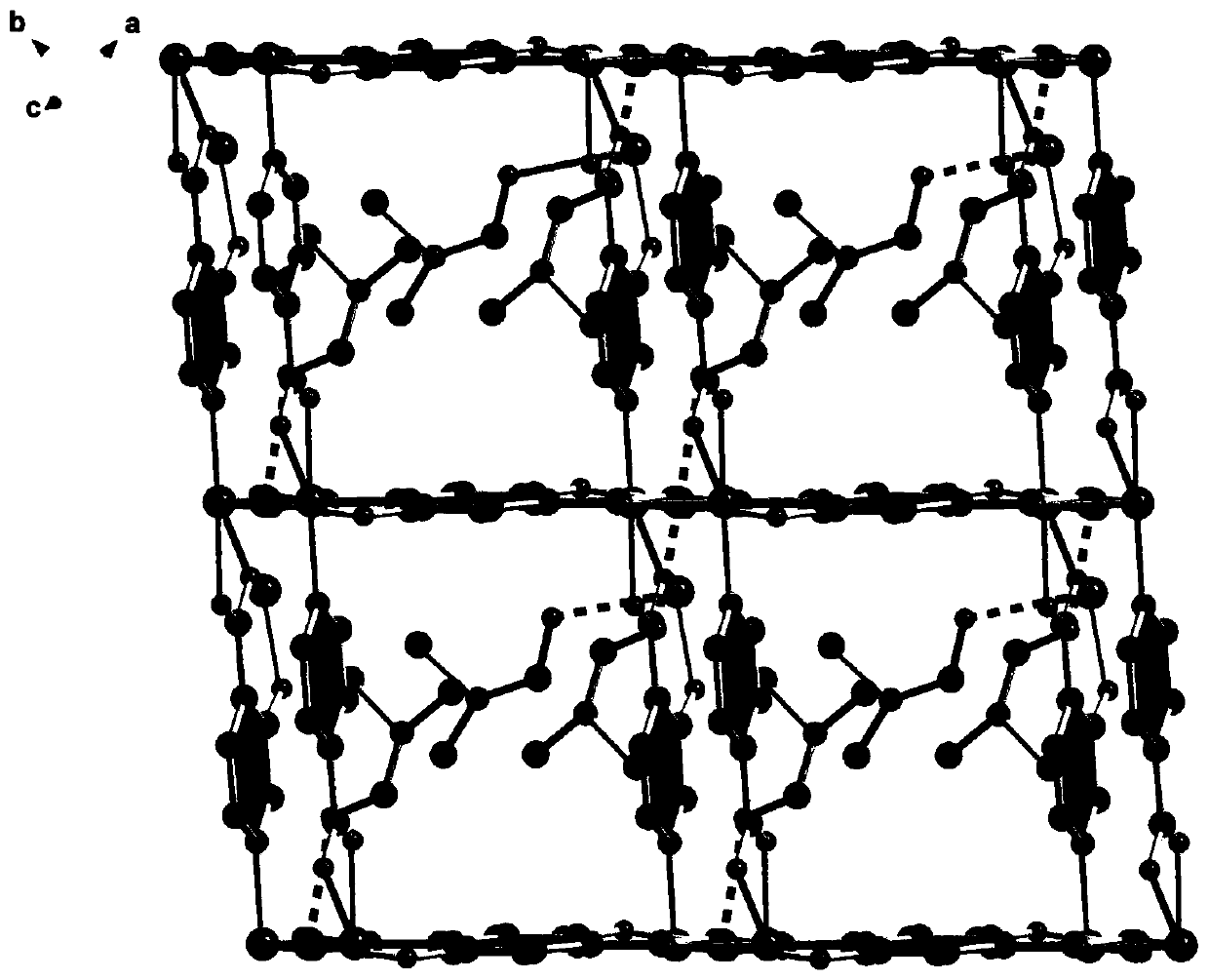

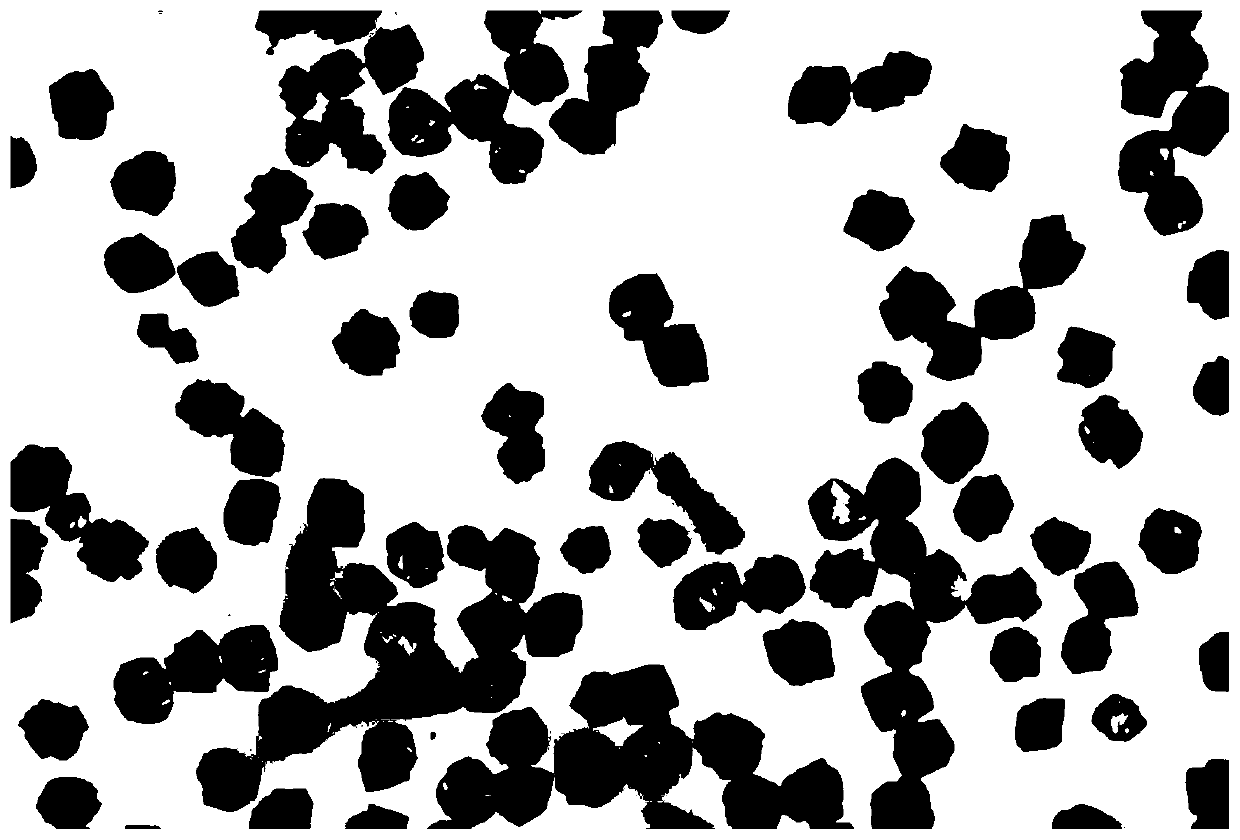

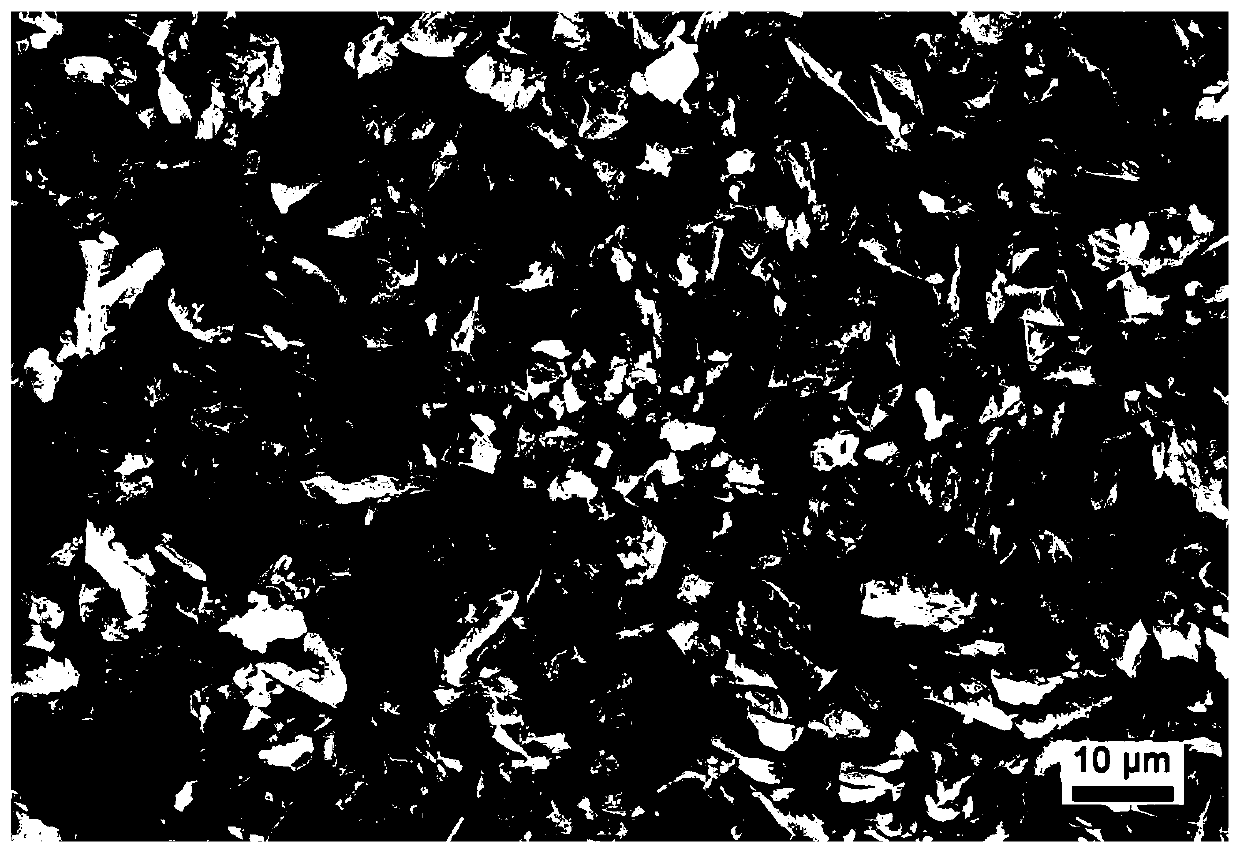

[0024] Step 2: Select a single crystal sample with a suitable size and good crystallization, collect diffraction data with a single crystal diffractometer at 250K, and then use the relevant structure analysis software Olex2 to refine and obtain the crystal structure. See the accompanying drawings for the specific structure. The purity of the bulk prepared samples was confirmed by X-ray powder diffraction techniques.

[0025] Step 3: In order to remove the solvent molecules in the pores of the material, the crystalline sample obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com