Quaternary lithium-rich manganese-based positive electrode material using Zn to replace Mn and preparation method of quaternary lithium-rich manganese-based positive electrode material

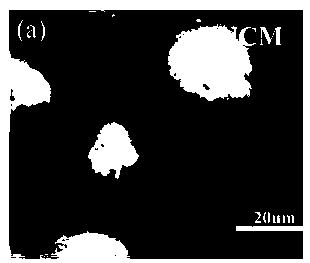

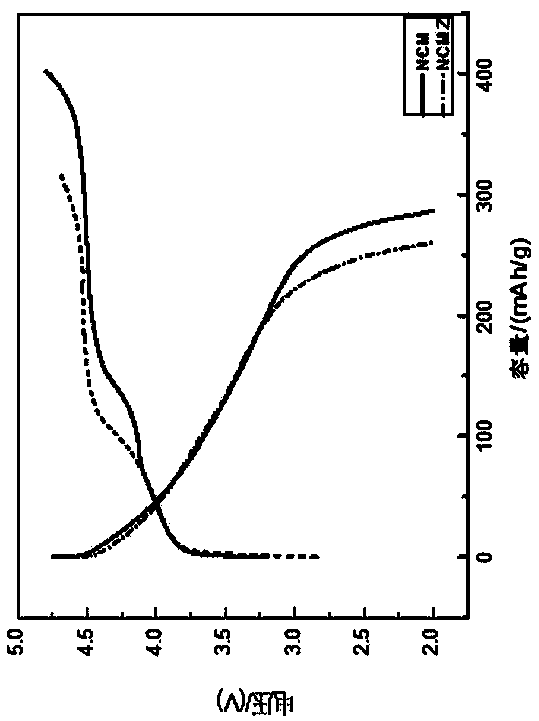

A cathode material, lithium-rich manganese-based technology, applied in the production field of lithium-rich manganese-based ternary cathode materials, can solve problems such as crystal structure collapse, achieve the effects of promoting grain growth, promoting lattice resonance, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] 1. Precursor preparation.

[0030] 1. Preparation of metal salt solution:

[0031] The following nickel salts can be any one of nickel sulfate, nickel nitrate or nickel acetate.

[0032] The following cobalt salts are any one of cobalt sulfate, cobalt nitrate or cobalt acetate.

[0033] The following manganese salts are any one of manganese sulfate, manganese nitrate or manganese acetate.

[0034] The following zinc salts are any one of zinc sulfate, zinc nitrate or zinc acetate.

[0035] Mix nickel salt, cobalt salt, manganese salt and zinc salt evenly, add deionized water, and prepare a metal salt aqueous solution with a metal cation concentration of 1-2 mol / L. Among them, the metal salt is composed of nickel, cobalt, manganese and zinc, and the molar numbers of the four ions of nickel, cobalt, manganese and zinc in the metal salt solution are o, y, z and 1-o-y-z respectively, and: 0.1<o ≤1, 0.1≤y≤1, 0.1≤z≤1, 0<1-o-y-z≤1.

[0036] In this embodiment, sulfate is u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com