Carbon encapsulation defect iron nano-catalyst, preparation method thereof and application of carbon encapsulation defect iron nano-catalyst in catalyzing peroxymonosulfate to degrade emerging pollutants

An iron nanometer and carbon encapsulation technology, which is applied in the direction of catalyst activation/preparation, water pollutants, chemical instruments and methods, etc., can solve the problems of metal-organic framework material structure instability, large pH value influence, low activation efficiency, etc., to achieve Easy to recycle, enhance effect, remove effect with good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

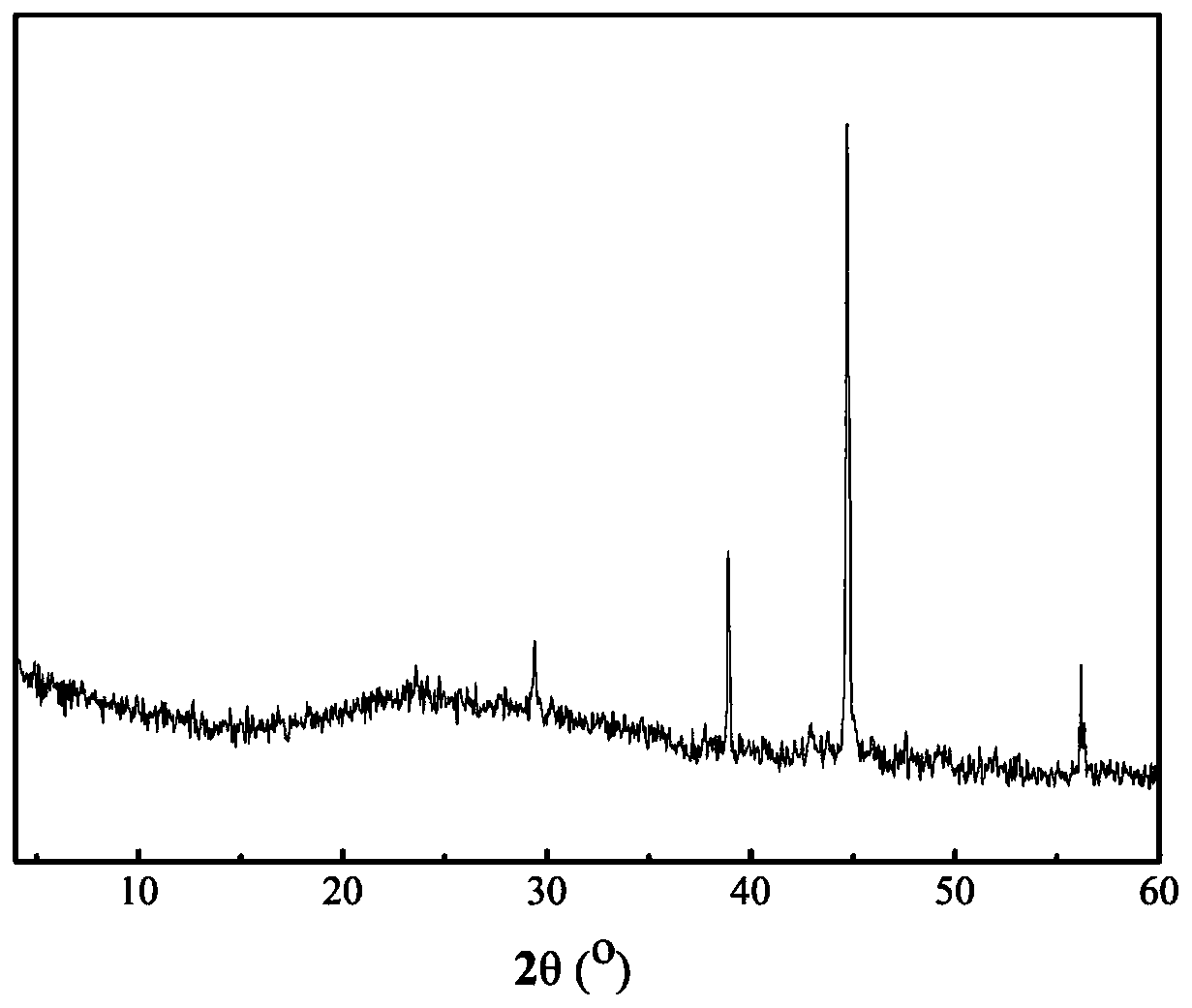

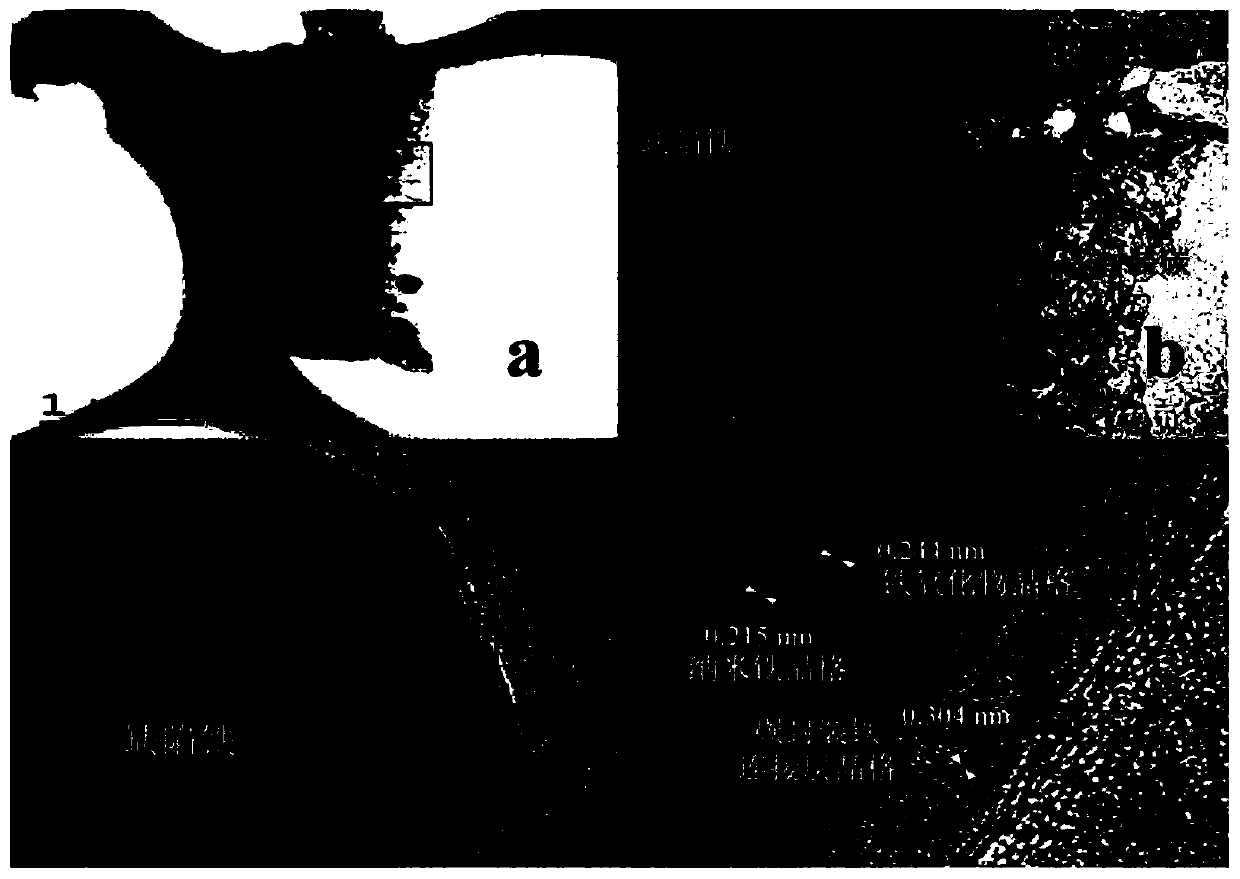

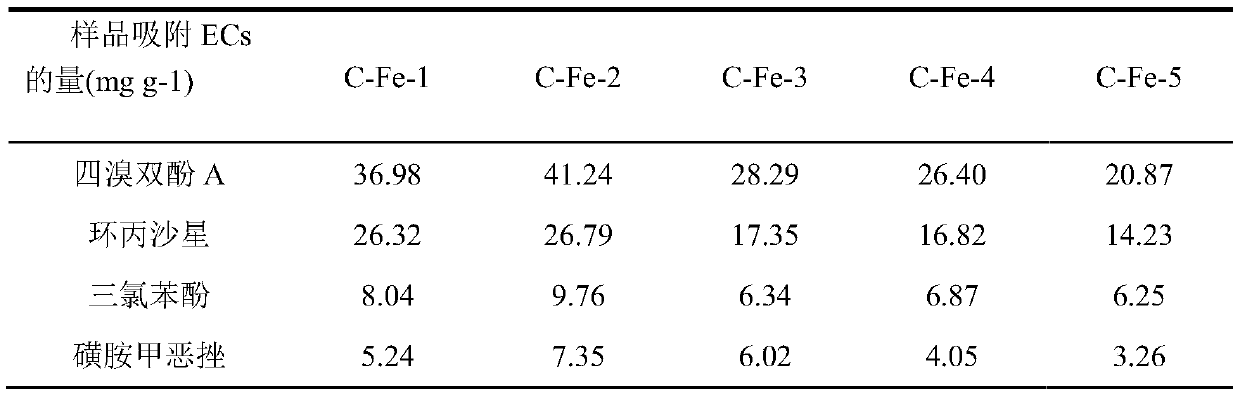

[0039] This example investigates the effect of adsorbing four kinds of ECs on carbon-encapsulated defect iron nanomaterials (C-Fe) prepared under different pyrolysis conditions.

[0040] (1) Preparation of carbon-encapsulated defect iron nanomaterials (C-Fe): take terephthalic acid (1.065g) and FeCl respectively 2 4H 2 O (2.65g) was placed in a 500ml there-necked flask, and 250ml of N,N-dimethylformamide was added to dissolve it, 30ml of methanol was added again, and 8ml of hydrofluoric acid was added dropwise to make the solution light green, and then heated to 140°C, reacted for 24h, and obtained the ferrous MOFs precursor. Then, the ferrous MOFs precursor was pyrolyzed at a high temperature in a tube furnace, and five black solid powders were obtained by pyrolysis under the following five pyrolysis conditions (pyrolysis temperature and time): 500°C & 2h, 650°C & 2h, 800°C & 2h, 650°C & 1h and 650°C & 3h; transfer these 5 kinds of black solid powders to 5 centrifuge tubes ...

Embodiment 2

[0048] This example investigates the effect of carbon-encapsulated defect iron nanomaterials (C-Fe) prepared under different pyrolysis conditions to activate PMS to degrade four kinds of ECs.

[0049] (1) The preparation method of the carbon-encapsulated defective iron nanomaterial (C-Fe) is the same as the step (1) in Example 1;

[0050] (2) Prepare concentration of 0.036mmol L respectively -1 Tetrabromobisphenol A solution, sulfamethoxazole solution, trichlorophenol solution and ciprofloxacin solution were used as ECs pollutants (0.036mmol L -1 ),spare;

[0051] (3) Using Erlenmeyer flasks as reactors, add 100 mL of the above four ECs pollutants to the four reactors (both concentrations are 0.036 mmol L -1 ), and then add 100mL of PMS solution (concentration of 0.36 mmolL -1 ), add 0.01g of C-Fe-1 to the 4 reactors respectively, place the 4 reactors in a 180rpm shaker, and carry out the degradation reaction at normal temperature (25°C); then test under the same conditions...

Embodiment 3

[0056] This example examines the effect of different molar ratios of PMS and tetrabromobisphenol A (n PMS / n ECs=1, 2, 3, 4, 5:1) on the catalytic activation of carbon-encapsulated defect iron nanomaterials (C-Fe) influences.

[0057] (1) Preparation of carbon-encapsulated defect iron nanomaterials (C-Fe): take terephthalic acid (1.065g) and FeCl respectively 2 4H 2 O (2.65g) was placed in a 500ml three-necked flask, and 250ml of N,N-dimethylformamide was added to dissolve it, then 30ml of methanol was added, and 8ml of hydrofluoric acid was added dropwise to make the solution light green, then heated to 140°C for 24h to obtain the ferrous MOFs precursor. Then, the ferrous MOFs precursor was subjected to high-temperature pyrolysis in a tube furnace, the pyrolysis temperature was 650° C., and the pyrolysis time was 2 hours to obtain a black solid powder. The black solid powder is transferred to a centrifuge tube, and the black solid powder is dissolved in 0.1mol L -1 Wash wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com