UiO-66 composite forward osmosis membrane and preparation and application thereof

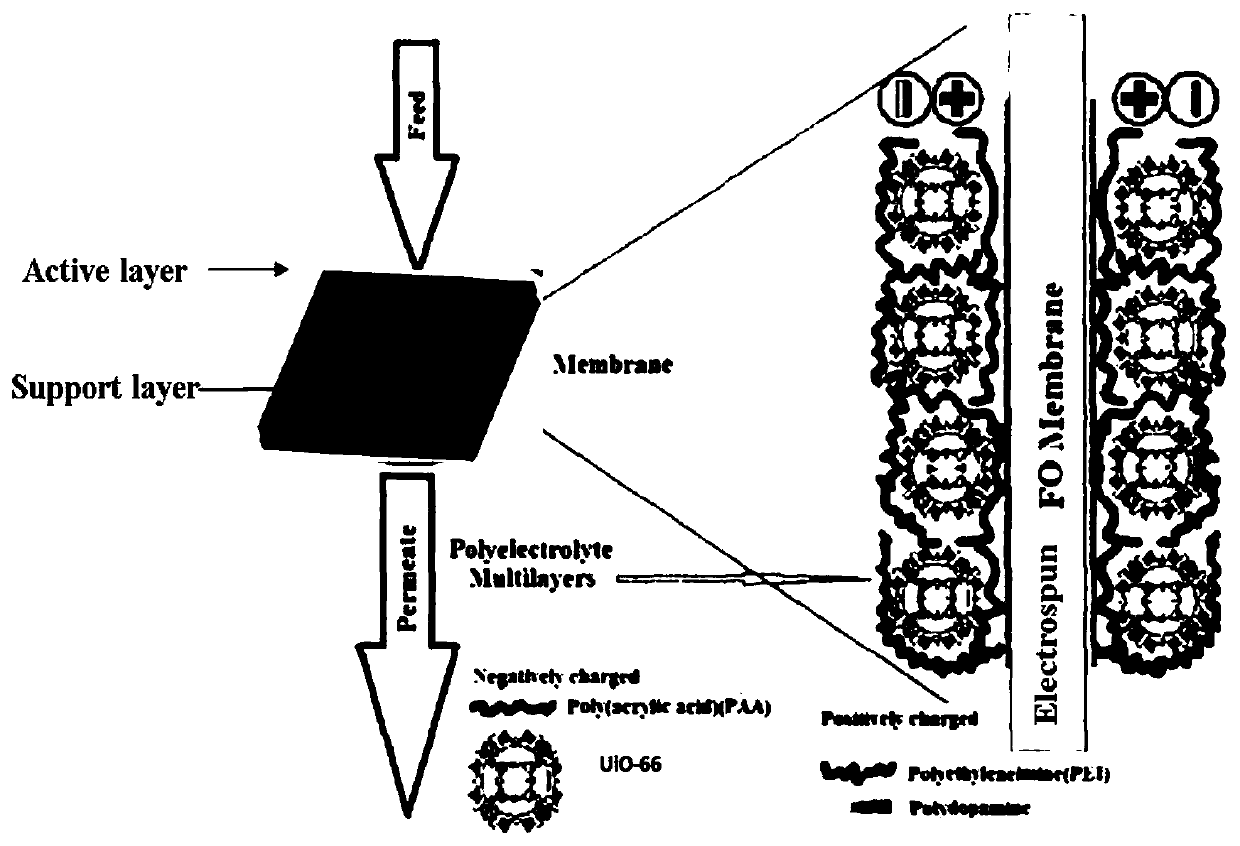

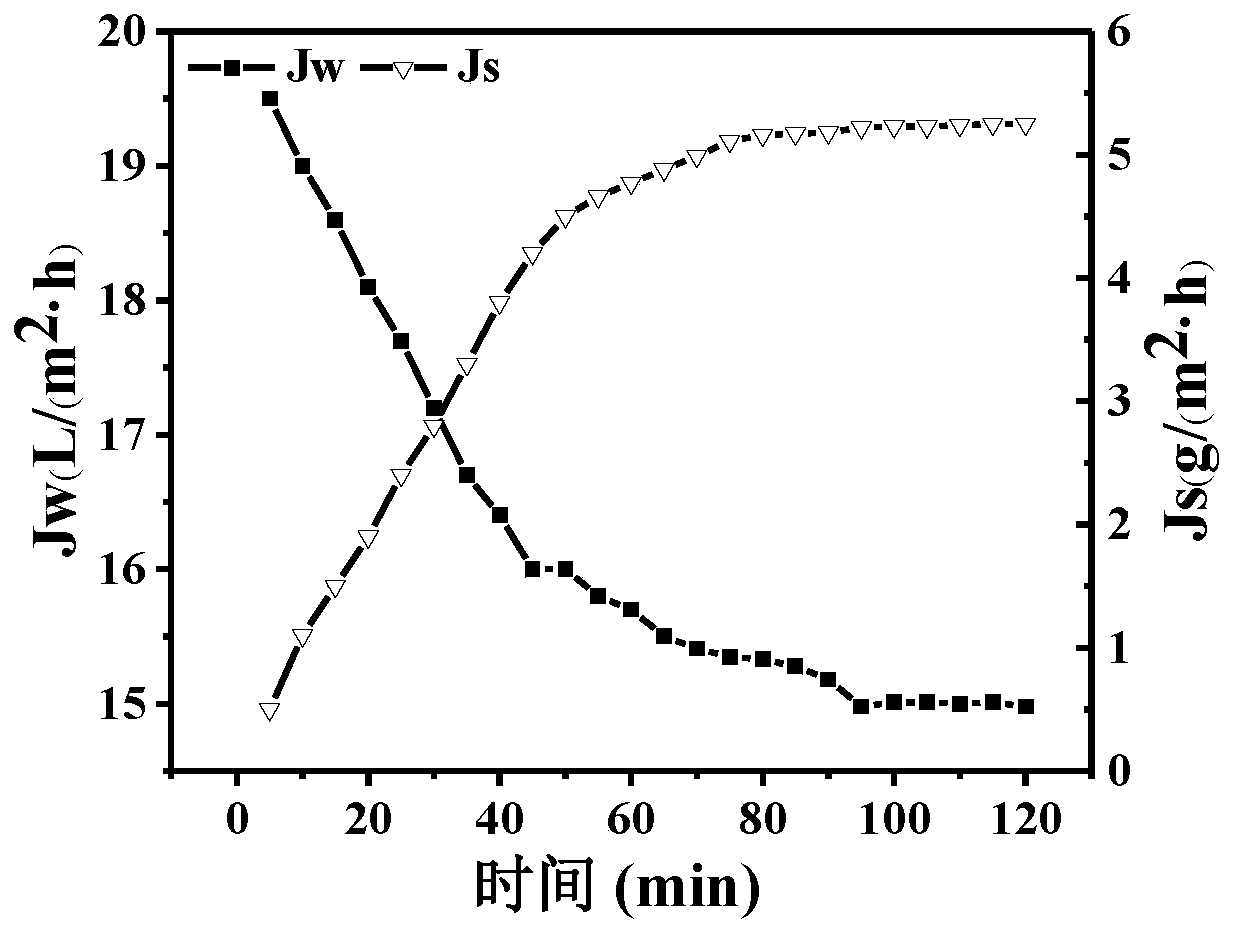

A forward osmosis membrane, uio-66 technology, applied in the field of forward osmosis membrane and its preparation and application, can solve the problems of forward osmosis membrane permeability, insufficient adsorption and retention capacity, etc., and achieve remarkable adsorption and retention capacity, good retention performance, compatibility good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

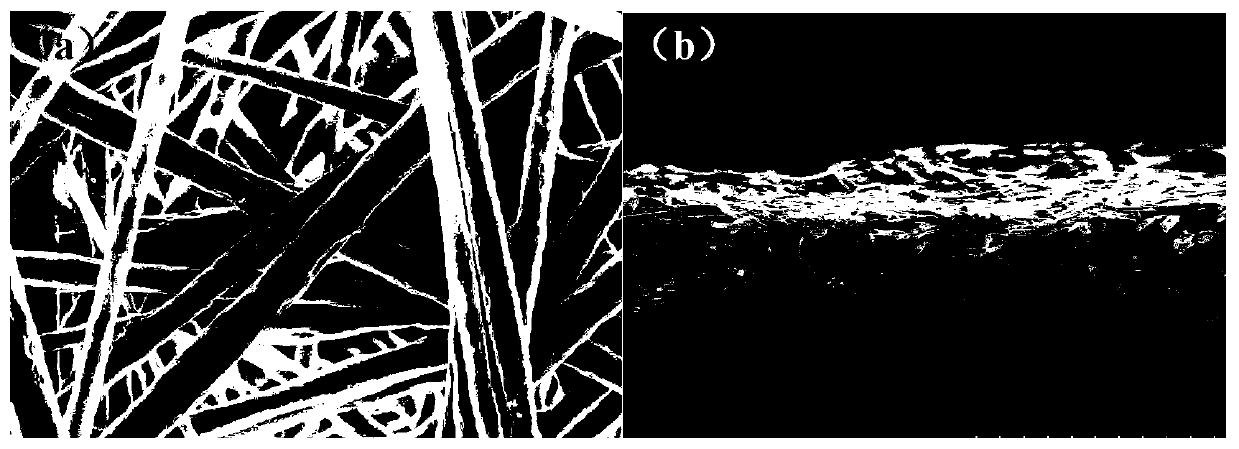

[0043] (1) Preparation of UiO-66: UiO-66 was prepared by solvothermal method. First, 0.2332g of anhydrous zirconium chloride and 0.1661g of terephthalic acid were dissolved in 50mL of N,N-dimethylformamide solution. and stirred for 5 minutes, then transferred to a 100 mL polytetrafluoroethylene-lined reactor, covered with a lid, and reacted in an oven at a temperature of 120° C. for 24 hours. After the reaction was completed, it was cooled to room temperature, and a white powdery substance UiO-66 was obtained after suction filtration. In addition, the resulting material was purified with methanol to remove unreacted terephthalic acid adsorbed on the pores. All the powder was transferred to a conical flask, methanol (50 mL) was added in batches, and the mixture was shaken continuously for one hour. The mixed solution was suction-filtered to obtain a white powder, which was vacuum-dried overnight in an oven at 120°C, and finally ground and sieved to obtain the UiO-66 required f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com