SAP-based machine-made sand ultra-high performance concrete and preparation method and application thereof

An ultra-high-performance, machine-made sand technology, applied in the field of building materials, to achieve the effect of improving the pumping performance of ultra-high-rise buildings, good durability and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

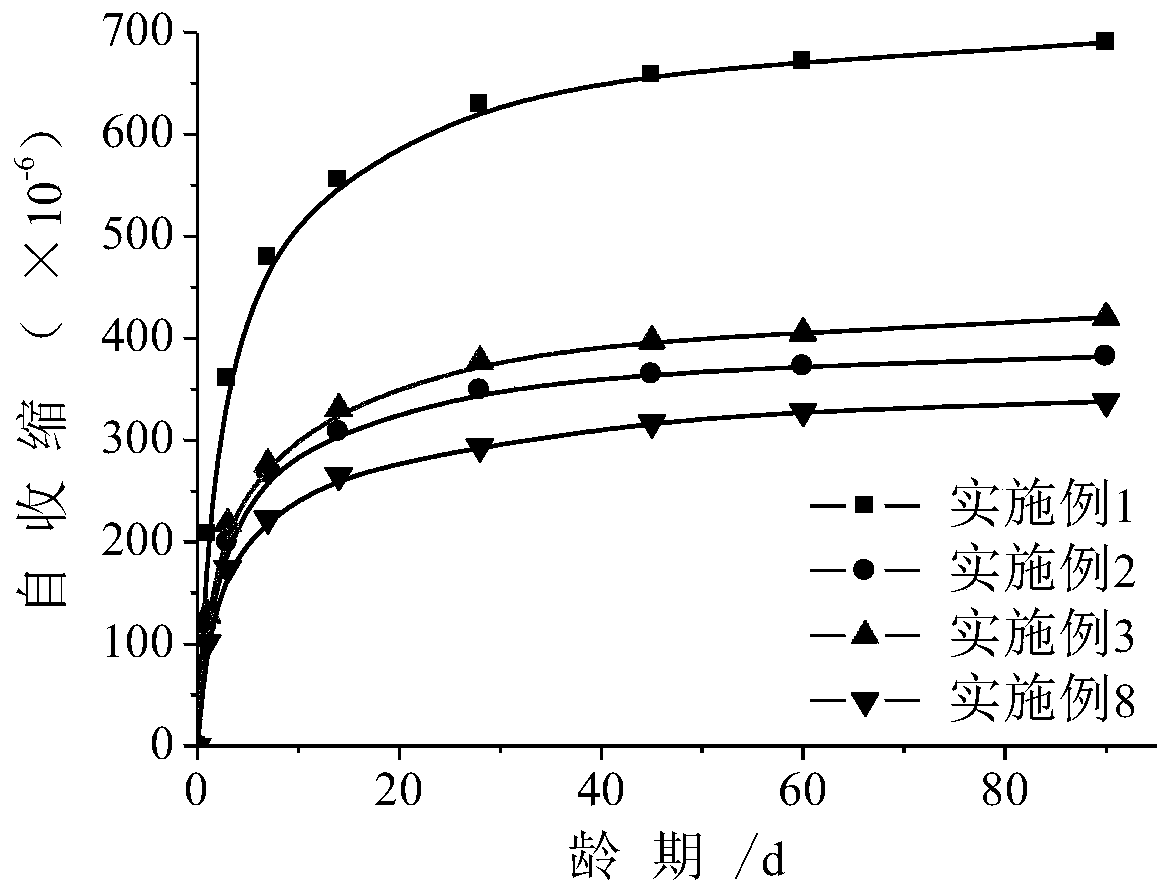

Embodiment 1

[0034] The machine-made sand ultra-high performance concrete without adding SAP and expansion agent includes the following components in parts by weight: 21 parts of cement; 4.6 parts of fly ash; 3.4 parts of silica fume; 28 parts of machine-made sand; 42 parts of gravel; parts; the water-binder ratio is 0.18. Among them, the cement used is Portland cement with P II 52.5; silica fume is produced by Chengdu Mingling Technology Co., Ltd., and its SiO 2 The content is 93%, the specific surface area is 21500m 2 / kg, moisture content 0.5%, water demand ratio 125%, loss on ignition 3.7%; use fly ash beads produced by Tianjin Zhucheng New Material Technology Co., Ltd.; machine-made sand: apparent density 2670kg / m 3 , packing density, 1560kg / m 3 , Contain mud / stone powder (3 , Crushing value 6.2%.

[0035] Its preparation method is as follows:

[0036] S1: Pour the cement, silica fume, fly ash microbeads, machine-made sand, and gravel weighed according to the weight components sta...

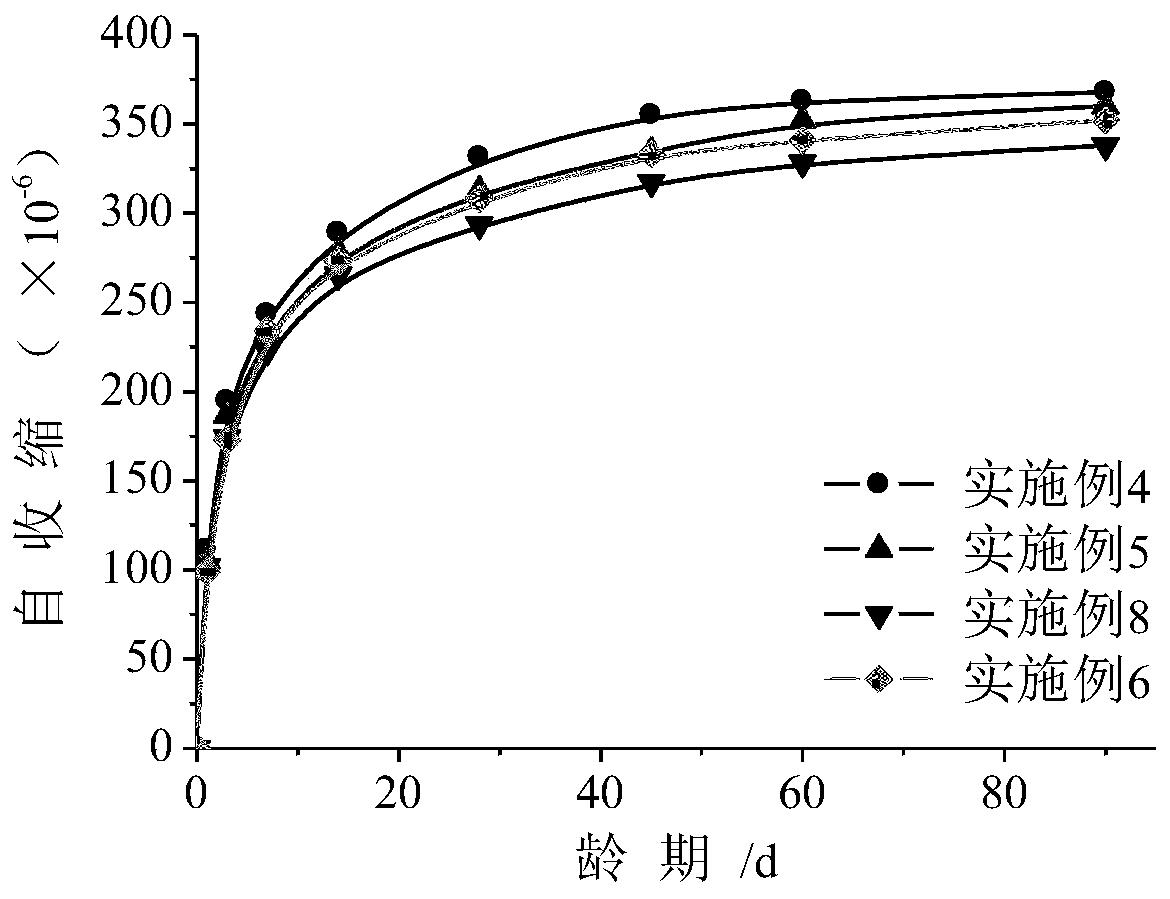

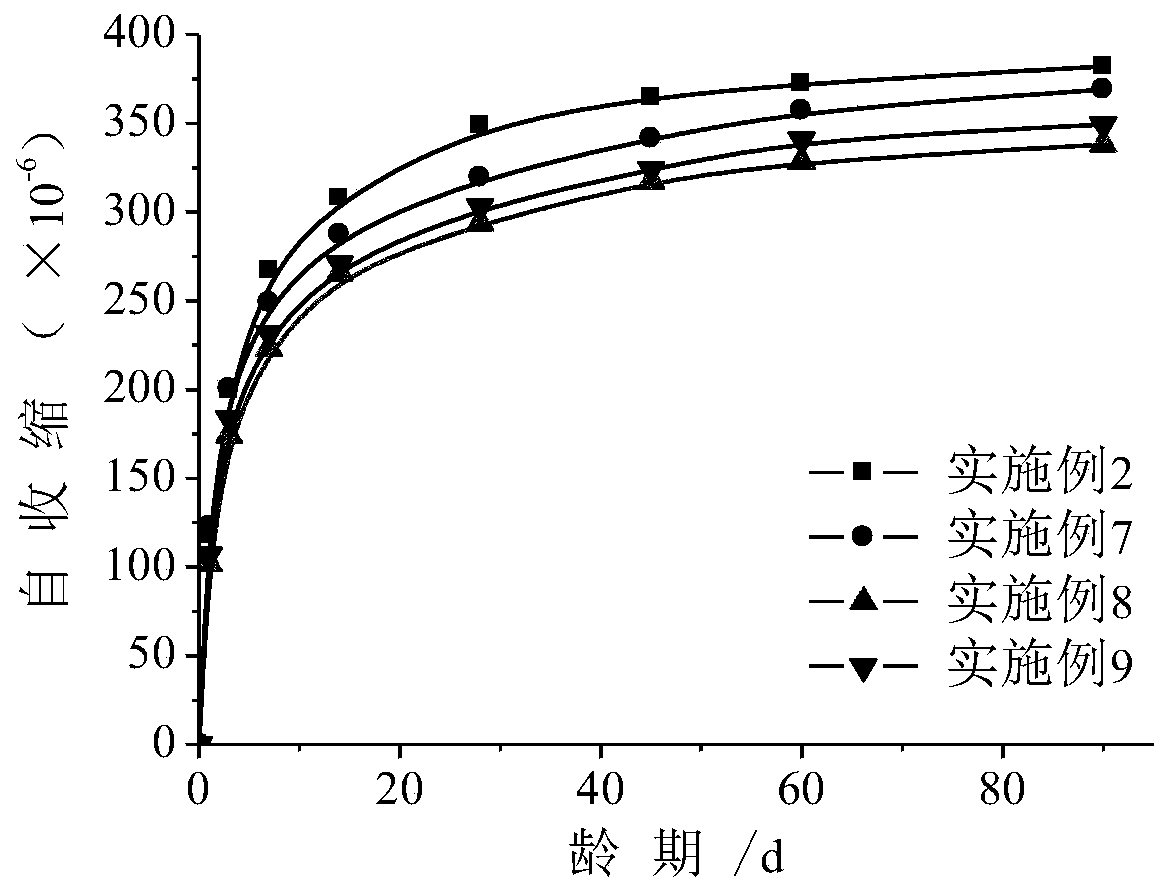

Embodiment 2

[0040] The machine-made sand ultra-high performance concrete without adding SAP but adding expansion agent includes the following components in parts by weight: 21 parts of cement; 4.6 parts of fly ash; 3.4 parts of silica fume; 28 parts of machine-made sand; 42 parts of crushed stone; parts; 0.5 parts of water reducing agent; water-binder ratio is 0.18. Among them, the cement used is Portland cement with P II 52.5; silica fume is produced by Chengdu Mingling Technology Co., Ltd., and its SiO 2 The content is 93%, the specific surface area is 21500m 2 / kg, moisture content 0.5%, water demand ratio 125%, loss on ignition 3.7%; use fly ash beads produced by Tianjin Zhucheng New Material Technology Co., Ltd.; machine-made sand: apparent density 2670kg / m 3 , packing density, 1560kg / m 3 , mud / stone powder content (3 , crushing value 6.2%; expansion agent is Subote composite expansion agent, which is prepared by compounding calcium sulfoaluminate-calcium oxide double expansion sourc...

Embodiment 3

[0046] The machine-made sand ultra-high performance concrete mixed with SAP without expansion agent includes the following components in parts by weight: 21 parts of cement; 4.6 parts of fly ash; 3.4 parts of silica fume; 28 parts of machine-made sand; 42 parts of gravel; Resin (SAP) 0.08 parts; water reducer 0.5 parts; water-binder ratio 0.18. Among them, the cement used is Portland cement with P II 52.5; silica fume is produced by Chengdu Mingling Technology Co., Ltd., and its SiO 2 The content is 93%, the specific surface area is 21500m 2 / kg, moisture content 0.5%, water demand ratio 125%, loss on ignition 3.7%; use fly ash beads produced by Tianjin Zhucheng New Material Technology Co., Ltd.; machine-made sand: apparent density 2670kg / m 3 , packing density, 1560kg / m 3 , mud / stone powder content (3 , Crushing value 6.2%. SAP selects polyacrylic acid sodium salt resin produced by a company in Tianjin. The particles are spherical and the particle size ranges from 75-125 μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com