Catalyst component for olefin polymerization, catalyst and olefin polymerization method

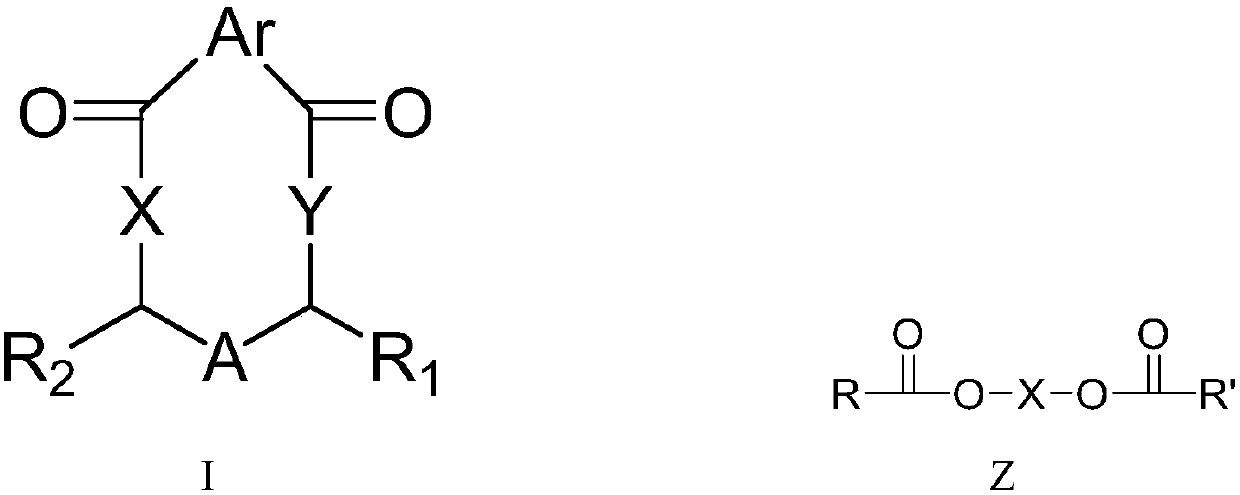

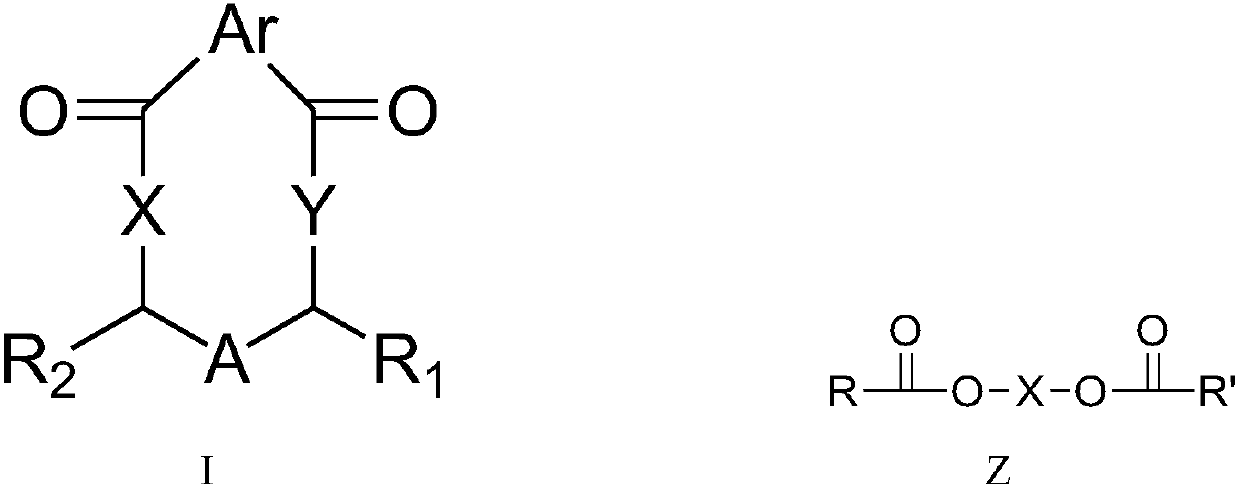

A technology for olefin polymerization and catalyst, which is applied in the field of catalyst components and can solve the problem that the overall effect of the catalyst is not outstanding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

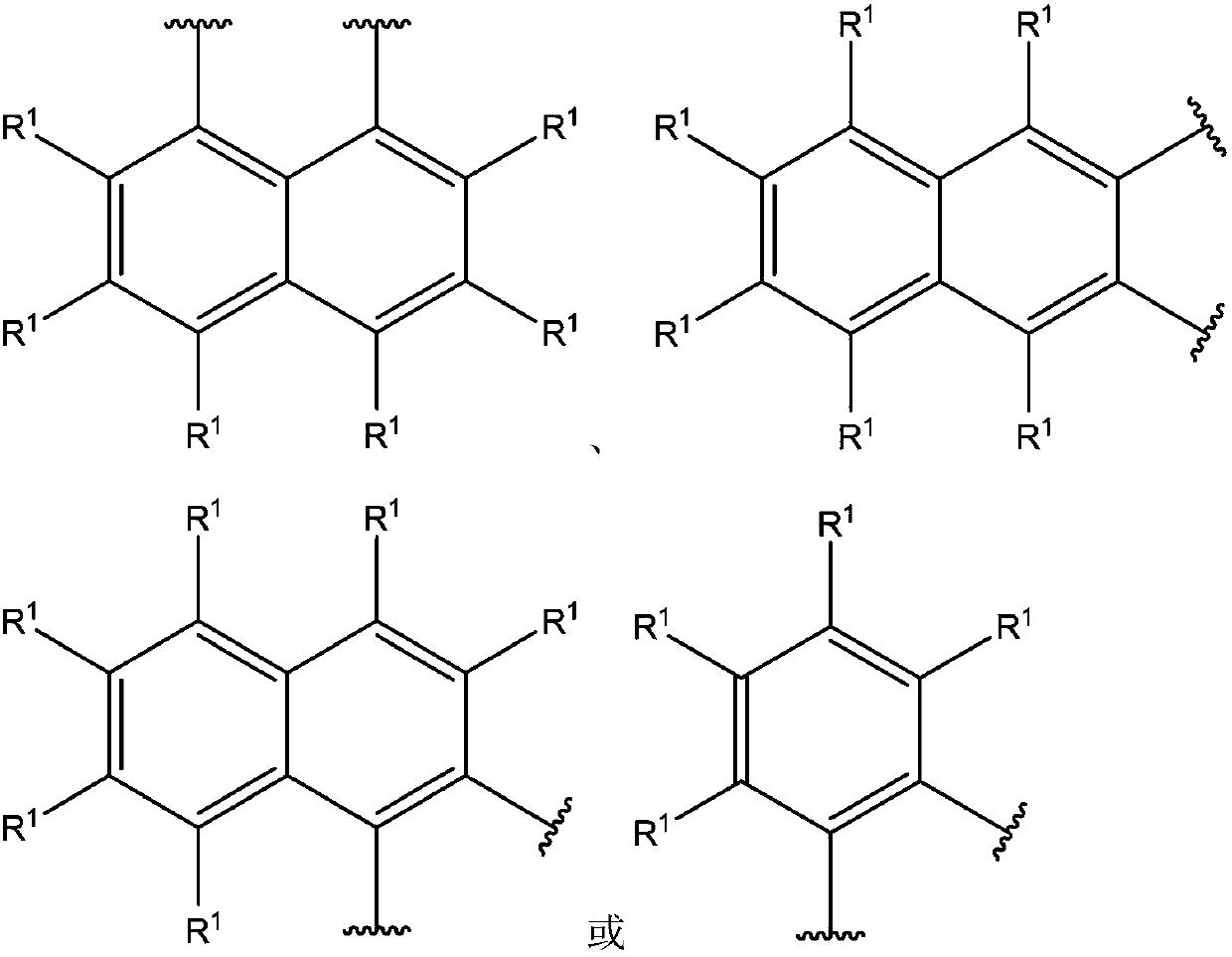

Method used

Image

Examples

Embodiment 1

[0049] Example 1 Synthesis of 2,4-dimethyl-7,9-naphtho[1',8'-gh]-1,5-dioxanane-6,10-dione (FE-1)

[0050] In a 250 ml three-necked flask, add 2.08 g of 2,4-pentanediol, 100 ml of acetonitrile, 2.15 ml of triethylamine, and 0.15 g of potassium chloride after purging with nitrogen, and drop 5.00 g of 1 , 8-naphthalene dicarbonyl chloride, stir well. Stir the reaction for 4 hours, then raise the temperature and reflux for 8 hours. After concentrating under reduced pressure, recrystallize from a mixed solution of diethyl ether / petroleum ether (1:50) to obtain pale yellow crystals, and dry in vacuo to obtain 2.04 g of the product (yield 36%). 1 H-NMR (δ, ppm, TMS, CDCl 3 ):8.33-8.32(2H,m,ArH),7.98-7.97(2H,m,ArH),7.47-7.46(2H,m,ArH),4.15-4.13(2H,m,OCH),2.25-2.24( 1H,m,CH 2 ),2.02-2.01(1H,m,CH 2 ),1.44-1.42(6H,m,CH 3 ).

[0051] The following compounds were synthesized using similar preparation methods.

[0052] 2,4-Dimethyl-7,8-benzo[g]-1,5-dioxonanane-6,9-dione (FE-2): Pale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com