Polyacrylic acid thickener taking modified attapulgite as cross-linking agent and preparation method of polyacrylic acid thickener

A technology of polyacrylic acid and cross-linking agent, which is applied in the direction of coating, etc., can solve the problems of application limitation, poor electrolyte resistance, etc., and achieve the effect of reducing production cost, high paste rate, and good cross-linking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

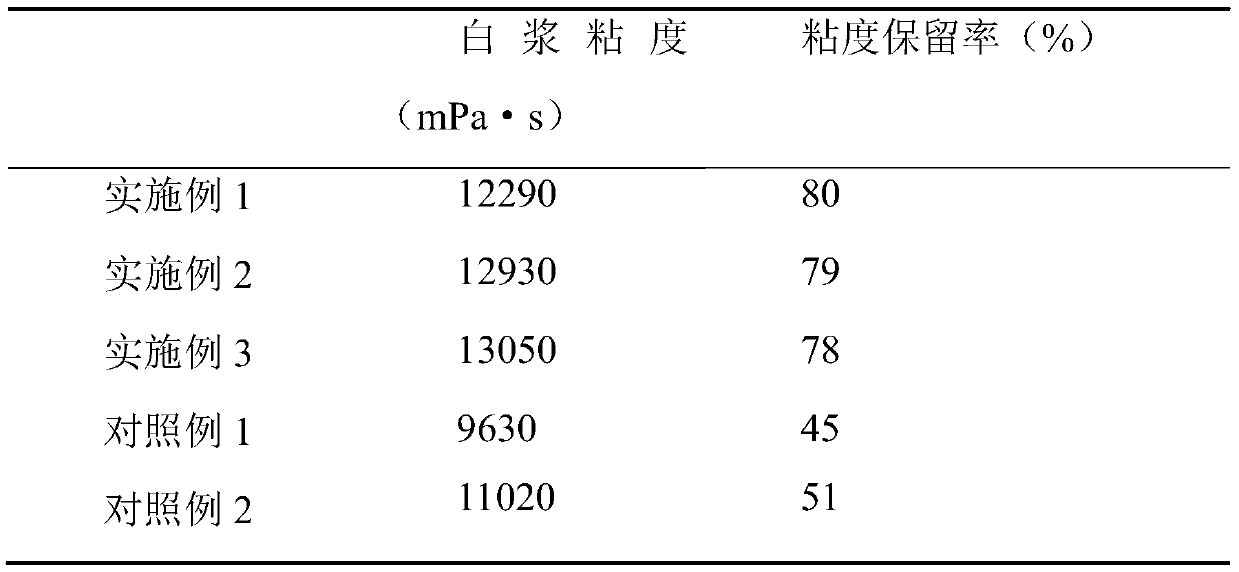

Examples

Embodiment 1

[0027] (1) Place attapulgite in 2mol / L nitric acid solution, ultrasonicate at 70°C for 60 minutes, wash with water until neutral, then centrifuge, dry, grind through a 400-mesh sieve, and set aside;

[0028] (2) Take 10g of the attapulgite treated in step (1), disperse it in toluene at a solid-to-liquid mass ratio of 1:10, disperse it ultrasonically for 10 minutes, and add the silane coupling agent γ-aminopropyltriethoxysilane dropwise , the mass ratio of silane coupling agent to attapulgite is 5:1, using glacial acetic acid to adjust the pH value of the system to 4.0, and stirring at room temperature for 48 hours. Joint agent modified attapulgite;

[0029] (3) Disperse 1 part (by weight) of the above-mentioned silane coupling agent-modified organoattapulgite in 10 parts (by volume) of methanol solution, and add acrylate dropwise at 50°C under stirring, and acrylate and The mass ratio of organic attapulgite modified by silane coupling agent is 3:1. After the dropwise addition...

Embodiment 2

[0034] (1) Place attapulgite in 2mol / L nitric acid solution, ultrasonicate at 80°C for 30min, wash with water until neutral, then centrifuge, dry, grind through a 400-mesh sieve, and set aside;

[0035] (2) Take 10g of the attapulgite treated in step (1), disperse it in xylene at a solid-to-liquid mass ratio of 1:30, disperse it ultrasonically for 30 minutes, and add the silane coupling agent γ-aminopropyltrimethoxysilane dropwise , the mass ratio of silane coupling agent to attapulgite is 8:1, using glacial acetic acid to adjust the pH value of the system to 5.0, stirring at room temperature for 96h, after the reaction, remove the solvent, dry in vacuum, grind through a 400-mesh sieve to obtain silane coupling agent Joint agent modified attapulgite;

[0036] (3) Disperse 1 part (by weight) of the above-mentioned silane coupling agent-modified organic attapulgite in 25 parts (by volume) of methanol solution, and add acrylate dropwise under stirring at 50 ° C. Acrylate and The...

Embodiment 3

[0041] (1) Place attapulgite in 2mol / L nitric acid solution, ultrasonicate at 75°C for 45min, wash with water until neutral, then centrifuge, dry, grind through a 400-mesh sieve, and set aside;

[0042] (2) Take 10 g of the attapulgite treated in step (1), disperse it in toluene at a solid-to-liquid mass ratio of 1:20, disperse it ultrasonically for 20 minutes, and add dropwise the silane coupling agent N-(β-aminoethyl)- γ-Aminopropyltrimethoxysilane, the mass ratio of silane coupling agent to attapulgite is 6:1, the pH value of the system is adjusted to 4.5 with glacial acetic acid, stirred at room temperature for 72 hours, after the reaction is completed, the solvent is removed, and vacuum-dried, Grinding through a 400-mesh sieve to obtain silane coupling agent-modified attapulgite;

[0043] (3) Disperse 1 part (by weight) of the above-mentioned silane coupling agent-modified organoattapulgite in 15 parts (by volume) of methanol solution, and add acrylate dropwise at 50 ° C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com