Castable polyurethane elastomer electrolyte and preparation method thereof

A polyurethane elastomer, electrolyte technology, applied in the direction of electrolyte immobilization/gelation, circuits, electrical components, etc., can solve the problems of low ionic conductivity at room temperature, poor mechanical properties and thermal stability, etc., to achieve good physical properties, good Comprehensive performance, high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

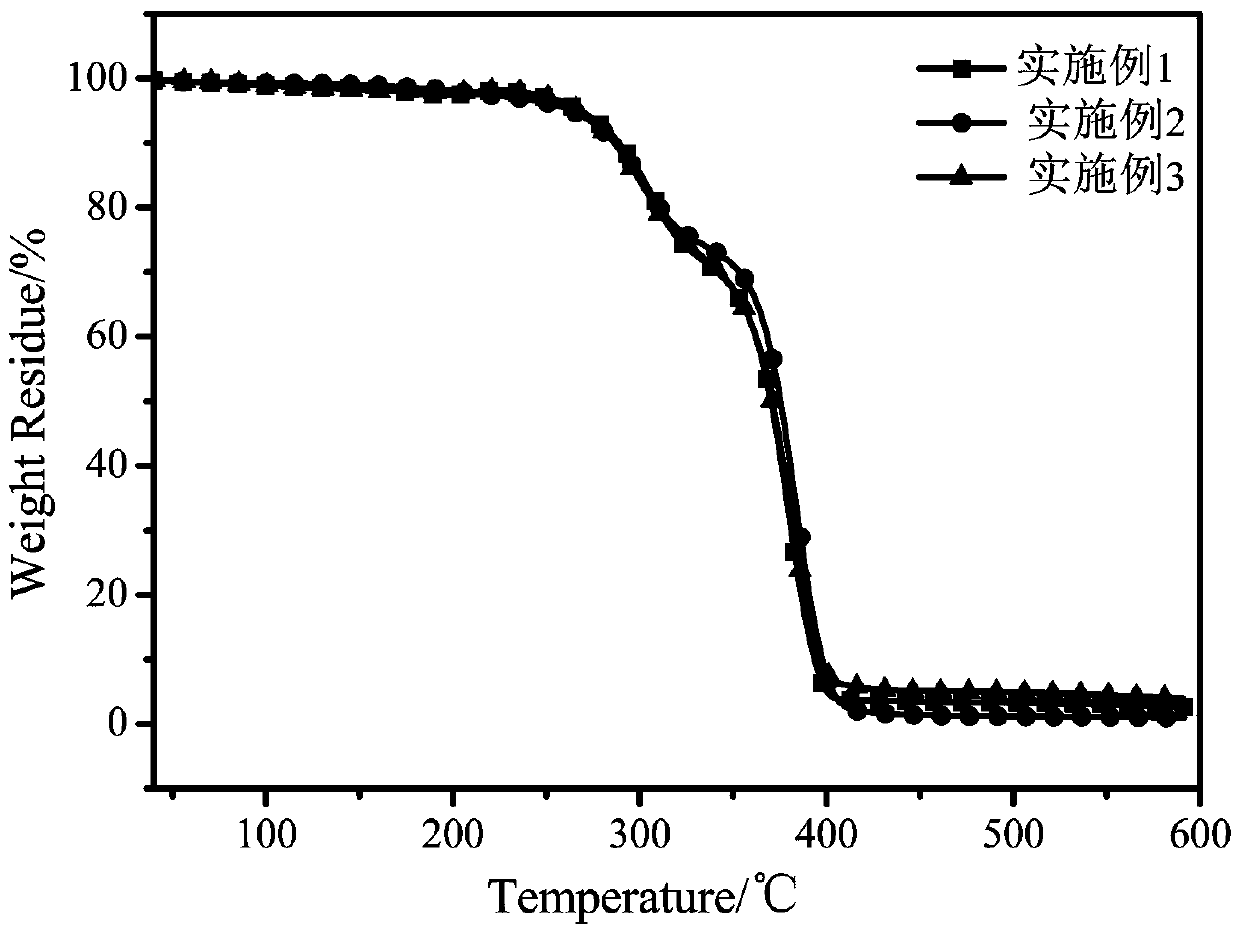

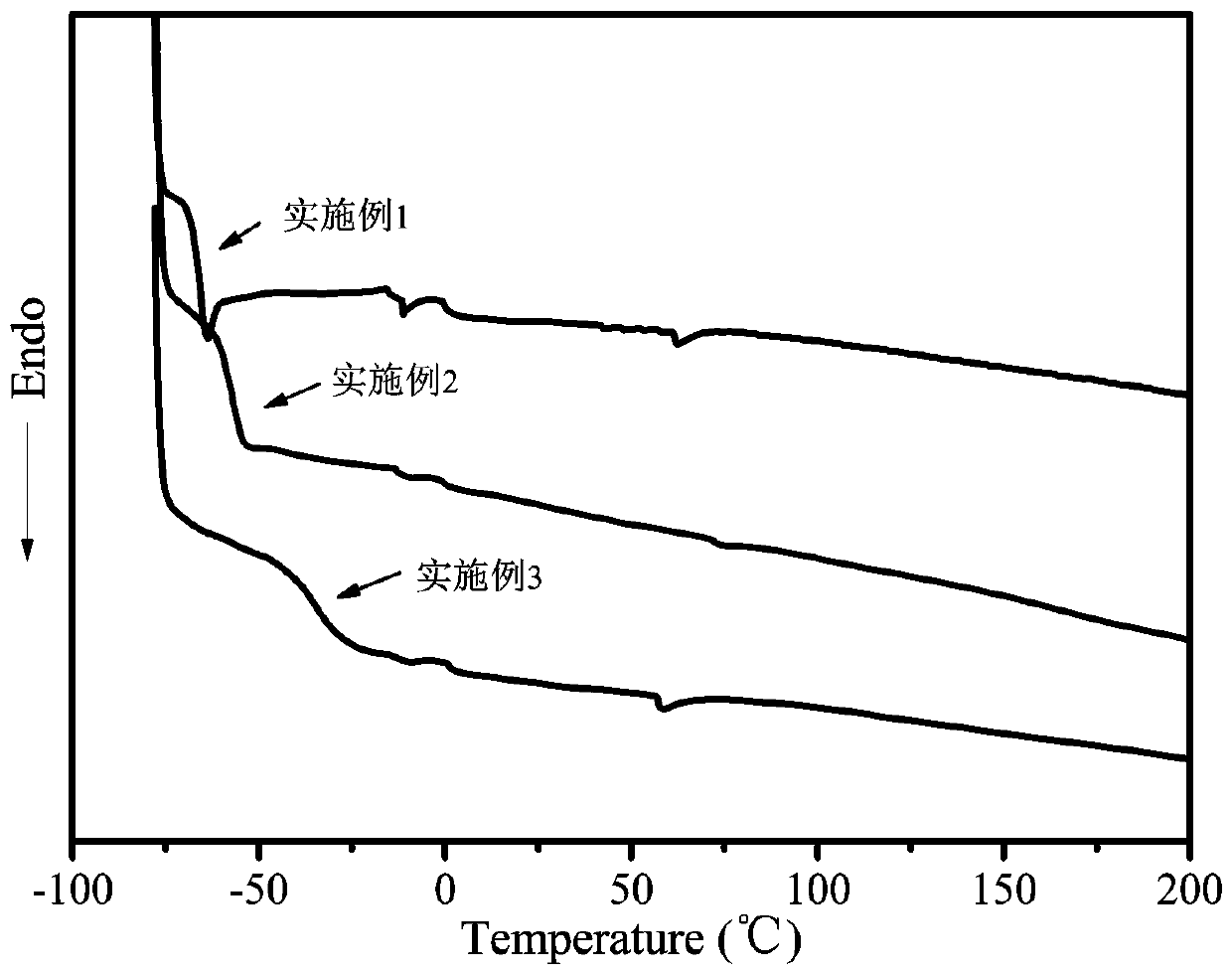

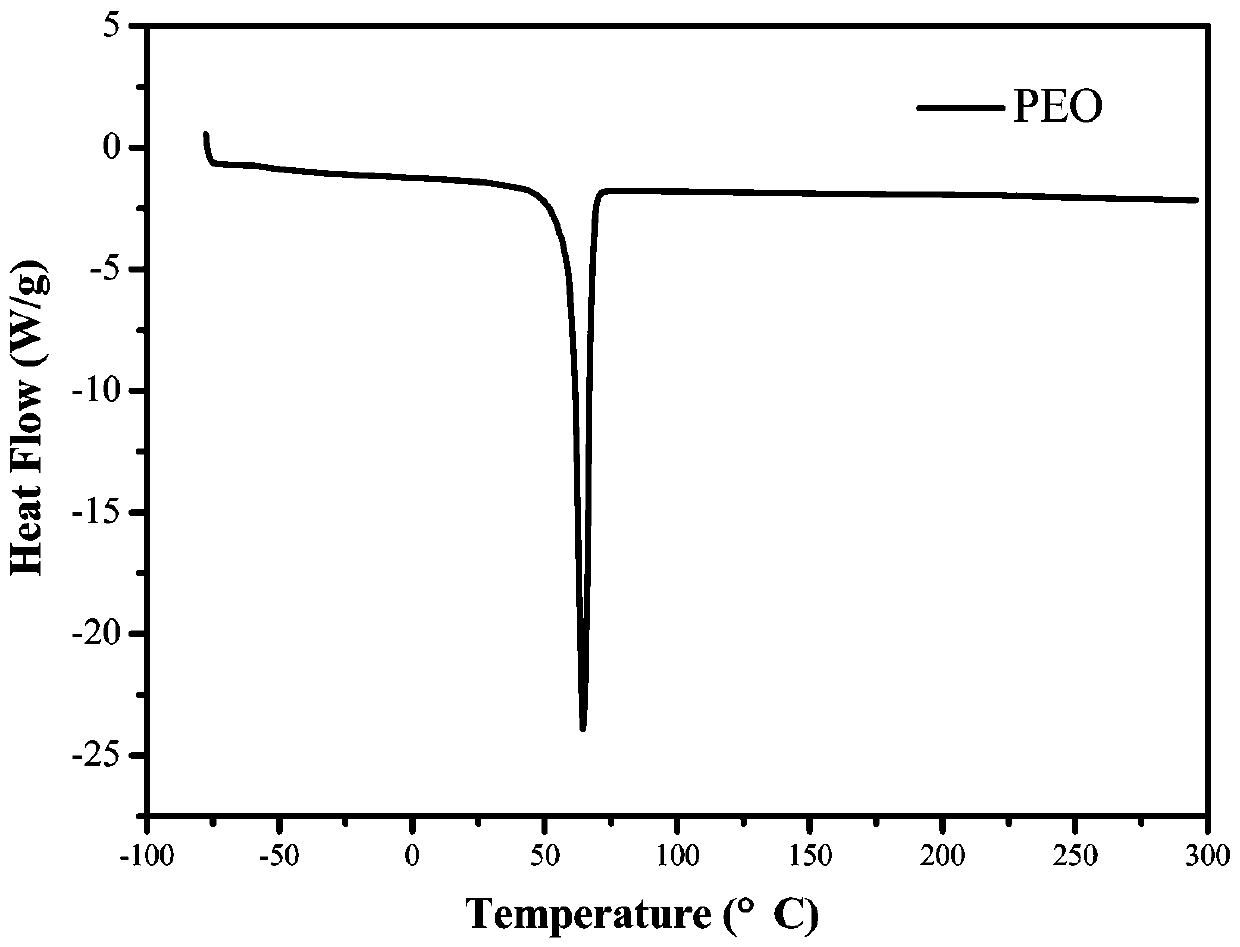

Embodiment 1

[0035] Weigh 35g PPG ( mn =2000), put into a three-necked flask equipped with a stirrer, a thermometer, a vacuum system and an electric heating mantle, and dehydrate under vacuum at 105°C for 1h. Cool down to 35°C, add 10g of TDI, after the natural temperature rise of the system stops, slowly raise the temperature to 70°C, and keep the reaction for 1.5h.

[0036] The reactant was lowered to room temperature, 11g LITFSI dissolved in 1g DMC was added, and the prepolymer was obtained after stirring for 90min to be fully uniform.

[0037] At room temperature, add pre-dehydrated 1g BDO, 2g DOP and 1g DBTL to the prepolymer prepared above, stir rapidly for 3min, and quickly put it into a vacuum device for degassing for 30s.

[0038]The mixture was quickly poured into molds coated with release agent and cured at room temperature for 7 days.

Embodiment 2

[0040] Weigh 40g PPG ( mn =1500), put it into a three-necked flask equipped with a stirrer, a thermometer, a vacuum system and an electric heating mantle, and dehydrate under vacuum at 100°C for 1h. Cool down to 30°C, add 10g of MDI, after the natural temperature rise of the system stops, slowly raise the temperature to 70°C, and keep the reaction for 1h.

[0041] The reactant was lowered to room temperature, 16g LITFSI dissolved in 2g DMC was added, and the prepolymer was obtained after stirring for 100min to be fully uniform.

[0042] At room temperature, add pre-dehydrated 2g BDO, 3g DOP and 2g DBTL to the prepolymer prepared above, stir rapidly for 3min, and quickly put it into a vacuum device for degassing for 50s.

[0043] The mixture was quickly poured into molds coated with release agent and cured at room temperature for 7 days.

Embodiment 3

[0045] Weigh 45g PPG ( mn =3000), put into a three-necked flask equipped with a stirrer, a thermometer, a vacuum system and an electric heating mantle, and vacuum dehydrate at 110°C for 1.5h. Cool down to 40°C, add 9g of TDI, after the natural temperature rise of the system stops, slowly raise the temperature to 80°C, and keep the reaction for 2h.

[0046] The reactant was lowered to room temperature, 20g LITFSI dissolved in 2.5g DMC was added, and the prepolymer was obtained after stirring for 200min to be fully uniform.

[0047] At room temperature, add pre-dehydrated 2.5g BDO, 4g DOP and 2.5g DBTL to the prepolymer prepared above, stir rapidly for 3min, and quickly put it into a vacuum device for degassing for 60s.

[0048] The mixture was quickly poured into molds coated with release agent and cured at room temperature for 8 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com