A kind of core-shell powder ultra-black material and preparation method thereof

An ultra-black material, core-shell technology, applied in chemical instruments and methods, metal material coating technology, other chemical processes, etc., can solve the problems of reducing the surface energy of ultra-black powder and low light absorption performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

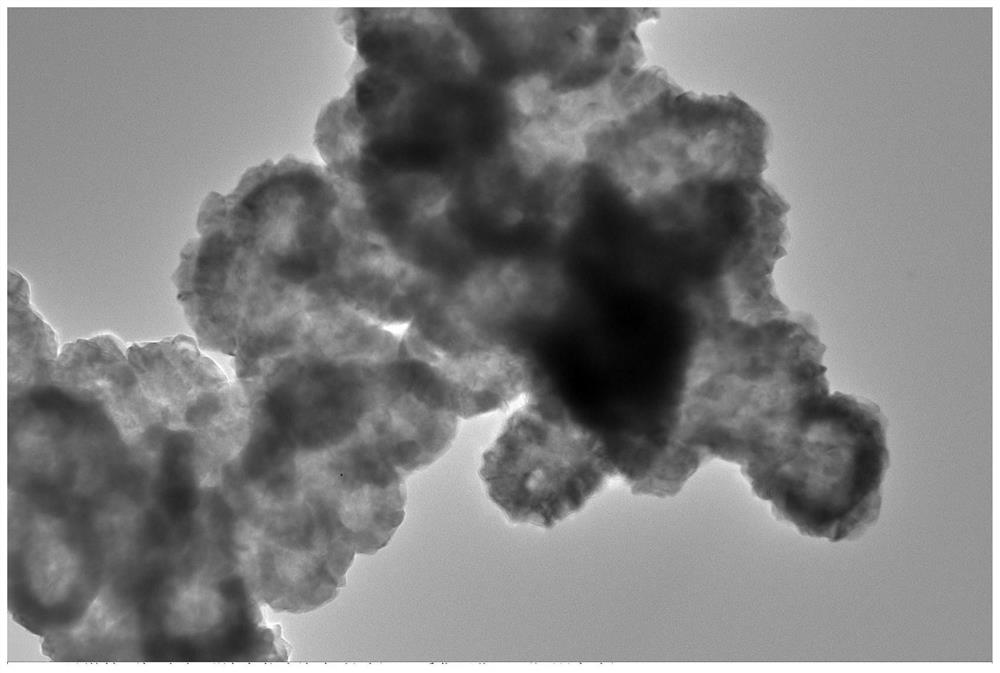

Image

Examples

specific Embodiment approach 1

[0027] Specific embodiment one: the specific steps of the preparation method of a core-shell type powder ultra-black material in this embodiment are as follows:

[0028] 1. ①Place carbon black powder with a particle size of 100nm in the reaction chamber, and under the conditions of temperature 150°C and pressure 0.15torr, pass diethyl zinc in the form of pulses for reaction, and the pulse time is 0.02s , and then feed nitrogen with a mass purity of 99.999% to purge the reaction residue, and the purge time is 40s; Purging the reaction residue with nitrogen with a mass purity of 99.999%, the purging time is 40s, step ① to step ② is a cycle;

[0029] 2. Repeat the cycle of step 1 100 times to complete the atomic layer deposition reaction, and obtain a core-shell powder ultra-black material with an oxide film deposited on the surface of the carbon black powder.

[0030] The thickness of the zinc oxide thin film in the core-shell powder ultra-black material obtained in this embodi...

specific Embodiment approach 2

[0031] Specific embodiment two: the specific steps of the preparation method of a core-shell type powder ultra-black material in this embodiment are as follows:

[0032] 1. ①Place carbon black powder with a particle size of 100nm in the reaction chamber, and under the conditions of temperature 150°C and pressure 0.15torr, pass diethyl zinc in the form of pulses for reaction, and the pulse time is 0.02s , and then feed nitrogen with a mass purity of 99.999% to purge the reaction residue, and the purge time is 40s; Purging the reaction residue with nitrogen with a mass purity of 99.999%, the purging time is 40s, step ① to step ② is a cycle;

[0033] 2. Repeat the cycle of step 1 for 150 times to complete the atomic layer deposition reaction, and obtain a core-shell powder ultra-black material with an oxide film deposited on the surface of the carbon black powder.

[0034] The thickness of the zinc oxide thin film in the core-shell powder ultra-black material obtained in this em...

specific Embodiment approach 3

[0036] Specific embodiment three: the specific steps of the preparation method of a core-shell type powder ultra-black material in this embodiment are as follows:

[0037] 1. ① Put the carbon black powder with a particle size of 100nm in the reaction chamber, and under the conditions of temperature 150°C and pressure 0.15torr, pass trimethylaluminum in the form of pulses for reaction, and the pulse time is 0.02s , and then feed nitrogen with a mass purity of 99.999% to purge the reaction residue, and the purge time is 40s; Purging the reaction residue with nitrogen with a mass purity of 99.999%, the purging time is 40s, step ① to step ② is a cycle;

[0038] 2. Repeat the cycle of step 1 100 times to complete the atomic layer deposition reaction, and obtain a core-shell powder ultra-black material with an oxide film deposited on the surface of the carbon black powder.

[0039] The thickness of the aluminum oxide thin film in the core-shell powder ultra-black material obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com