Mineral oil defoamer

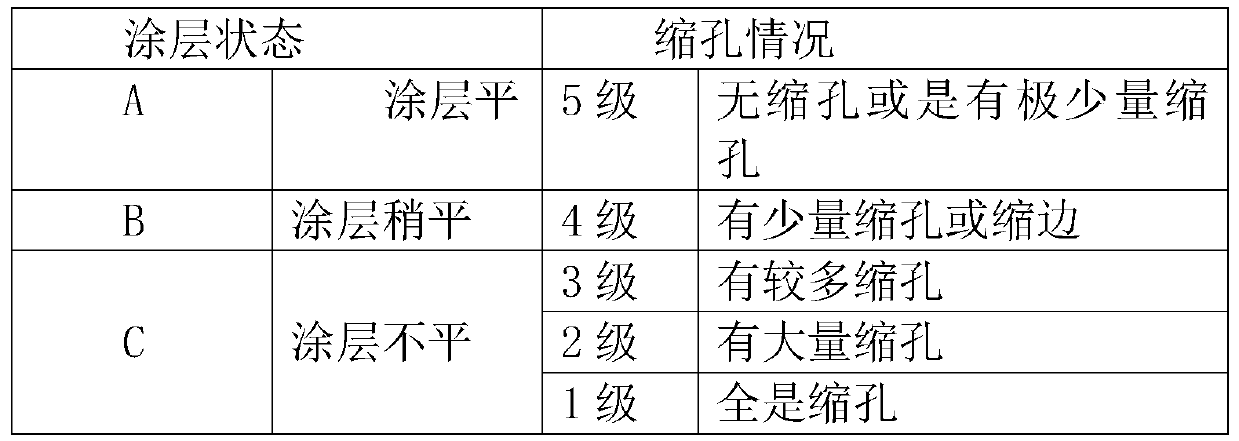

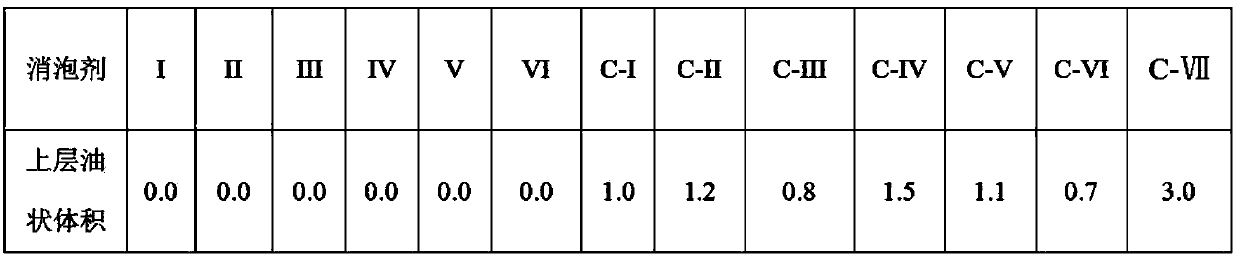

A technology of mineral oil and defoamer, which is applied in the direction of foam dispersion/prevention, chemical instruments and methods, liquid degassing, etc. It can solve problems such as poor defoaming performance, coating defects, affecting coating appearance and quality, etc. Achieve the effect of improving anti-foaming performance and stability, and solving shrinkage cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

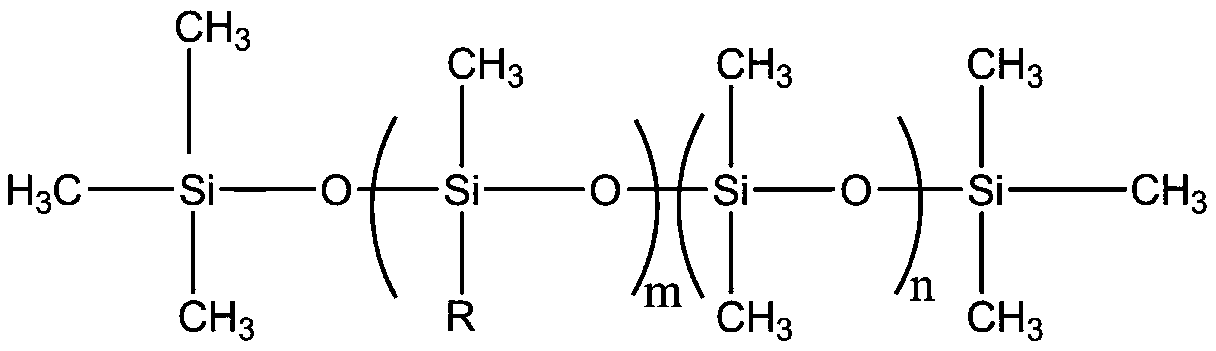

[0032] Embodiment 1, a kind of mineral oil defoamer, 21g alkyl silicone oil (the average carbon number is 1.3, and the carbon atom number in the group R is 10) and 2g precipitated silica are mixed, and at 2000rpm rotating speed Disperse at high speed for 10 minutes, raise the temperature to 100°C, and keep it warm for 0.5h to obtain mixture A, and the kinematic viscosity at 25°C reaches 3000mPa·s.

[0033]Then add 317g 5# white oil, 577g peanut oil and epoxidized peanut oil thereof in container, add 9g aluminum hexadecanoate while stirring, 13g aluminum dioctoate, 23g oxidized polyethylene wax, 25g stearic acid, and above-mentioned mixture A, then continue to stir for 15min. Immediately after slowly raising the temperature to 140°C and keeping it warm for 0.5h, then cooling down to 80°C, adding 18g of sorbitan trioleate (Span-85) and continuing to stir for 60min to obtain mixture B.

[0034] At room temperature, the mixture B was dispersed in a high-speed disperser at a speed...

Embodiment 2

[0035] Embodiment 2, a kind of mineral oil defoamer, 96g alkyl silicone oil (average carbon number is 2.1, and the number of carbon atoms in the group R is 14) is mixed with 45g precipitated silica, and rotates at 2000rpm Disperse at high speed for 10 minutes, raise the temperature to 160°C, and keep it warm for 2 hours to obtain mixture A, and the kinematic viscosity at 25°C reaches 4000mPa·s.

[0036] Then add 127g7# white oil, 673g soybean oil and its amidated soybean oil in container, add 30g bis(docosanoate) aluminum while stirring, 0.5g polyoxypropylene glycol, 0.5g n-stearyl alcohol, With the above mixture A, and then continue to stir for 10min. Immediately after slowly raising the temperature to 180°C and keeping it warm for 3h, then cooling down to 80°C, adding 28g of polyoxyethylene sorbitan trioleate (Tween-85) and continuing to stir for 60min to obtain mixture B.

[0037] At room temperature, the mixture B was dispersed in a high-speed disperser at a speed of 3000...

Embodiment 3

[0038] Embodiment 3, a kind of mineral oil defoamer, 11g alkyl silicone oil (average carbon number is 4.1, and the number of carbon atoms in the group R is 18) is mixed with 4g precipitated silica, and rotates at 2000rpm Disperse at high speed for 10 minutes, raise the temperature to 130°C, and keep it warm for 1.2h to obtain mixture A, and the kinematic viscosity at 25°C reaches 5000mPa·s.

[0039] Then add 170 alkylbenzenes, 630g castor oil and epoxidized castor oil thereof in the container, add 20g aluminum di(octadecanoate) while stirring, 15g isobutyl phosphate, 10g ethylene glycol diester stearate , and the above mixture A, and then continue to stir for 30min. Immediately after slowly raising the temperature to 140°C and keeping it warm for 3h, then cooling down to 60°C, adding 140g of oleic acid polyoxyethylene (6) ether, and continuing to stir for 60min to obtain mixture B.

[0040] At room temperature, the mixture B was dispersed in a high-speed disperser at a speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com