A microwave-assisted method for large-scale preparation of carbon nanospheres from lignin

A technology for large-scale preparation and nano-carbon spheres, applied in nanotechnology, carbon preparation/purification, etc., can solve the problems of long and complex steps, poor controllability of morphology, difficulty in large-scale preparation, etc., and reduce preparation steps and costs. The effect of low cost and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

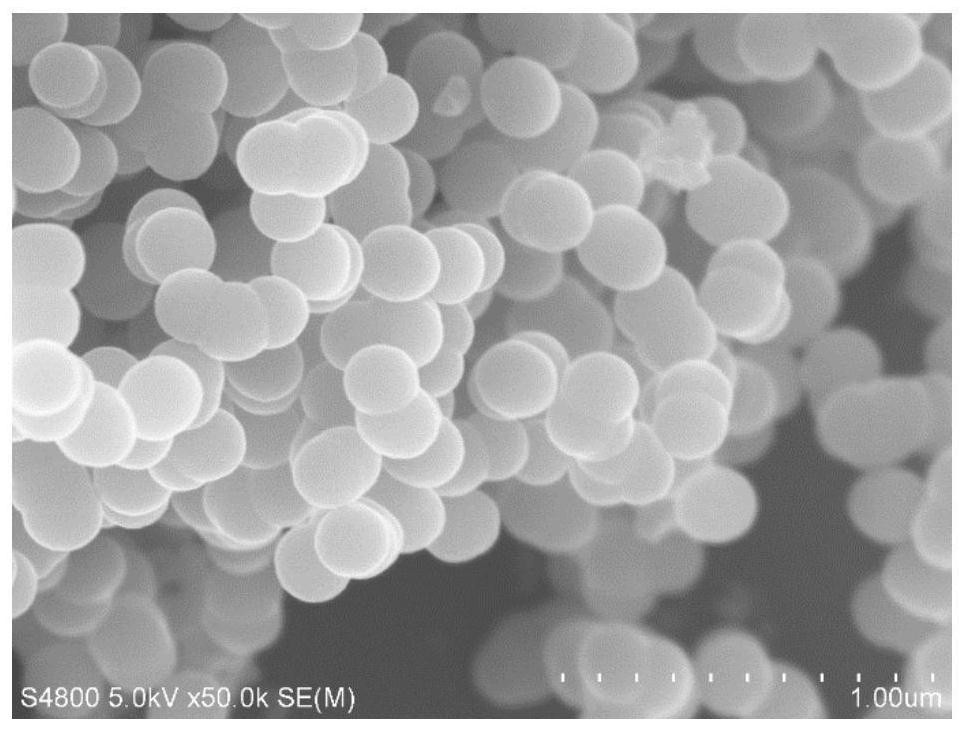

Embodiment 1

[0037] Mix 5 kg of alcoholyzed lignin with a particle size of 60 to 80 mesh and 2.5 kg of silicon carbide with a particle size of 20 to 60 mesh evenly, place it in a microwave tube reactor, and feed nitrogen at a flow rate of 2.5 L / min for 15 minutes, then Nitrogen is passed through the Montessori gas scrubber bottle equipped with dichloromethane to make the nitrogen carry dichloromethane, and the carrying amount is 2.5g / min. After passing the nitrogen carrying dichloromethane into the microwave tube reactor for 10 minutes, turn on the microwave In a tubular reactor, the microwave frequency is 2.45GHz, the microwave power is 300W, the temperature is raised to 400°C, and the temperature is kept for 10 minutes; then the microwave power is adjusted to 1200W, the temperature is raised to 800°C, and the temperature is kept for 60 minutes. Close the microwave tube reactor, remove the Montessori scrubber bottle containing dichloromethane, keep feeding nitrogen, and stop feeding nitrog...

Embodiment 2

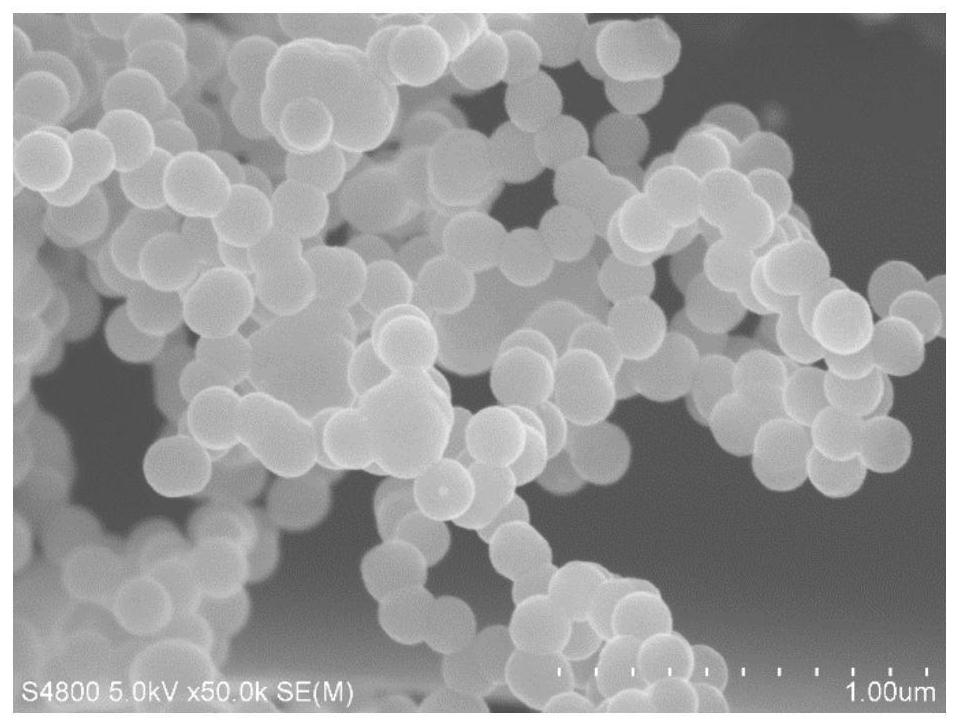

[0039]Mix 20kg of kraft lignin with a particle size of 80-100 mesh and 60kg of silicon carbide with a particle size of 80-100 mesh evenly, place it in a microwave tube reactor, and feed nitrogen at a flow rate of 40L / min for 15 minutes, and then nitrogen Make the nitrogen carry the dichloromethane through the Montessori gas scrubber bottle equipped with dichloromethane, and the carrying amount is 200g / min. After passing the nitrogen gas carrying the dichloromethane into the microwave tube reactor for 10 minutes, start the microwave tube reaction The microwave frequency is 2.45GHz, the microwave power is 500W, the temperature is raised to 500°C, and the temperature is kept for 5 minutes; then the microwave power is adjusted to 1500W, the temperature is raised to 1200°C, and the temperature is kept for 30 minutes. Close the microwave tube reactor, remove the Montessori scrubber bottle containing dichloromethane, keep feeding nitrogen, and stop feeding nitrogen when the temperatur...

Embodiment 3

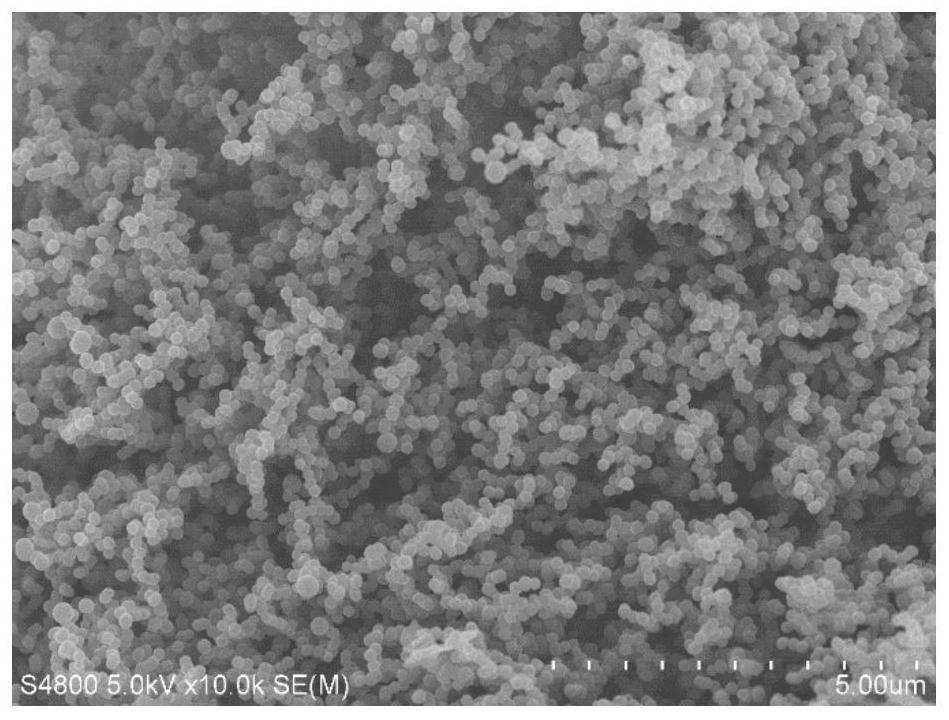

[0041] Mix 10kg of lignosulfonate with a particle size of 80-120 mesh and 20kg of silicon carbide with a particle size of 40-80 mesh evenly, place it in a microwave tube reactor, and feed nitrogen at a flow rate of 10L / min for 15 minutes, and then put Nitrogen passes through the Montessori gas scrubber bottle equipped with dichloromethane to make the nitrogen carry dichloromethane, and the carrying amount is 30g / min. After passing the nitrogen carrying dichloromethane into the microwave tube reactor for 10 minutes, turn on the microwave tube reactor. In the reactor, the microwave frequency is 2.45GHz, the microwave power is 400W, the temperature is raised to 450°C, and the temperature is kept for 8 minutes; then the microwave power is adjusted to 1300W, the temperature is raised to 1000°C, and the temperature is kept for 40 minutes. Close the microwave tube reactor, remove the Montessori scrubber bottle containing dichloromethane, keep feeding nitrogen, and stop feeding nitroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com