System and method for producing optical glass grade potassium nitrate from sodium nitrate high-temperature mother liquor

A technology of potassium nitrate and sodium nitrate, applied in directions such as the preparation of alkali metal nitrates, can solve the problems of low raw material yield and product qualification rate, high energy consumption, high water consumption, etc., to improve energy utilization and reduce process energy. Consumption and reduce the effect of operation links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the scope of the present invention is not limited thereto, and the technical solution and actual Circumstances to determine the specific implementation.

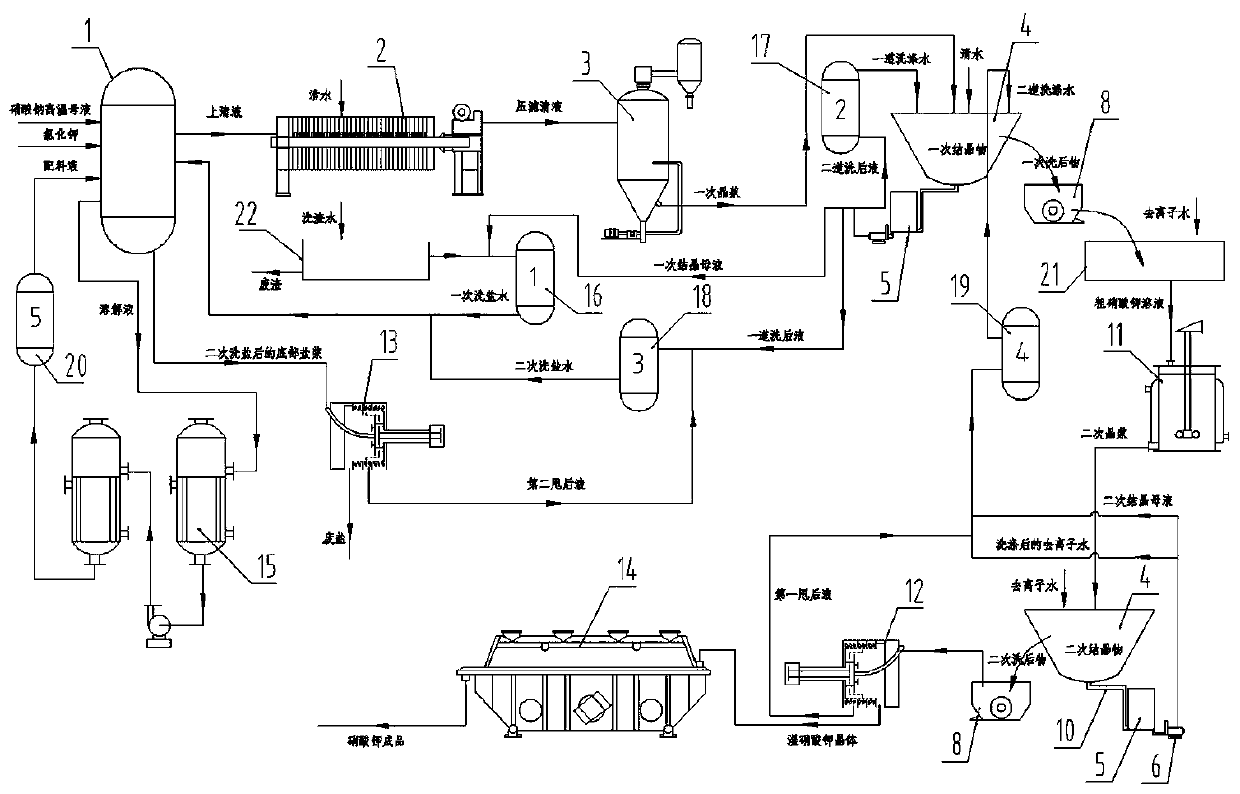

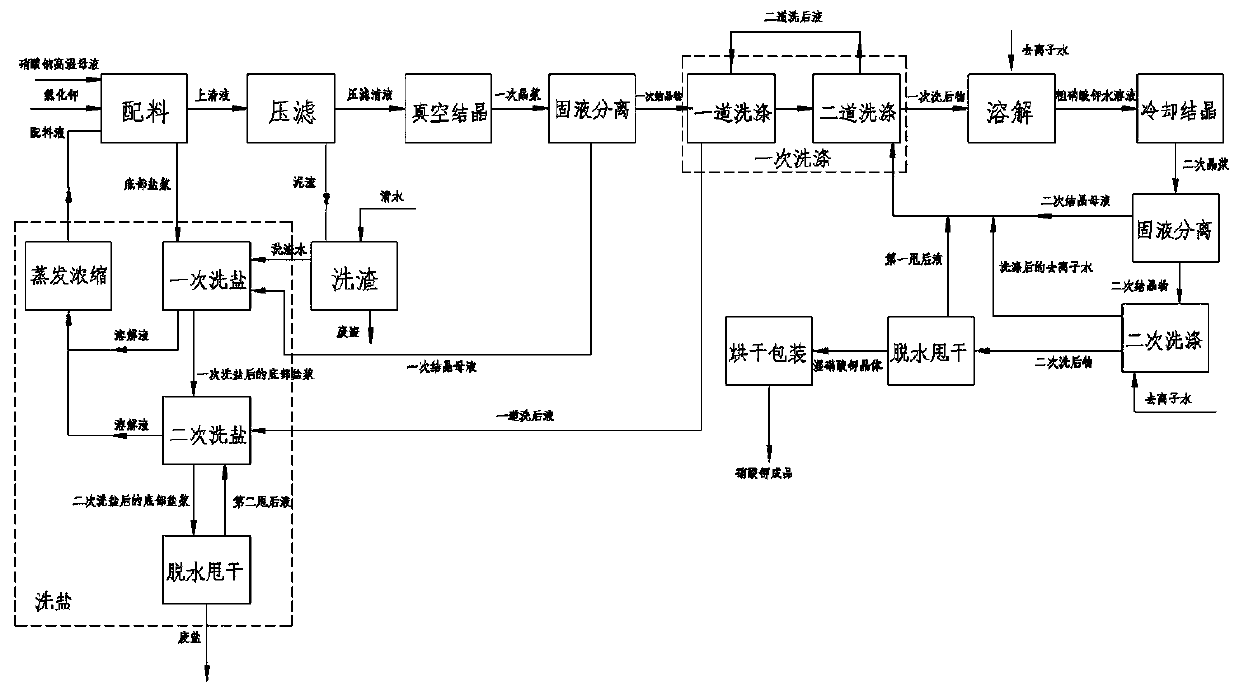

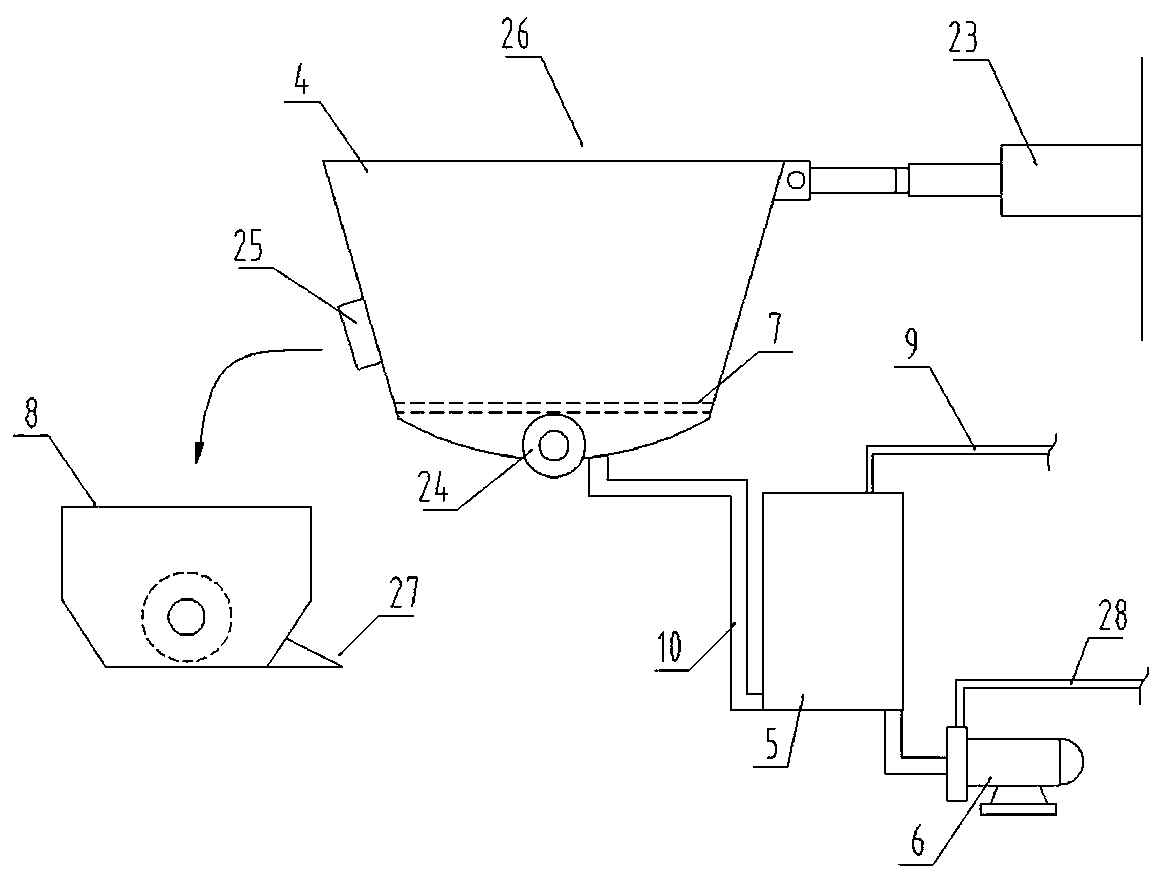

[0035] as attached figure 1 , 3 As shown, the system for producing optical glass-grade potassium nitrate with sodium nitrate high-temperature mother liquor includes a batching tank 1, a plate and frame filter press 2, a vacuum crystallizer 3, a first filter washing device, a dissolution tank 21, a cooling crystallizer 11, a Two filtering and washing devices, the first two-stage pusher centrifuge 12, the second two-stage pusher centrifuge 13, a fluidized bed dryer 14, a two-effect evaporator 15, a heating device and a stirring device are installed in the batching tank 1, A li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com