Preparation method of self-cleaning outdoor artificial stone plate

A technology for artificial stone slabs and cleaners, applied in the field of artificial stone, can solve problems such as difficult cleaning and low durability performance, and achieve the effects of less mold consumption, improved compactness, and improved self-cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

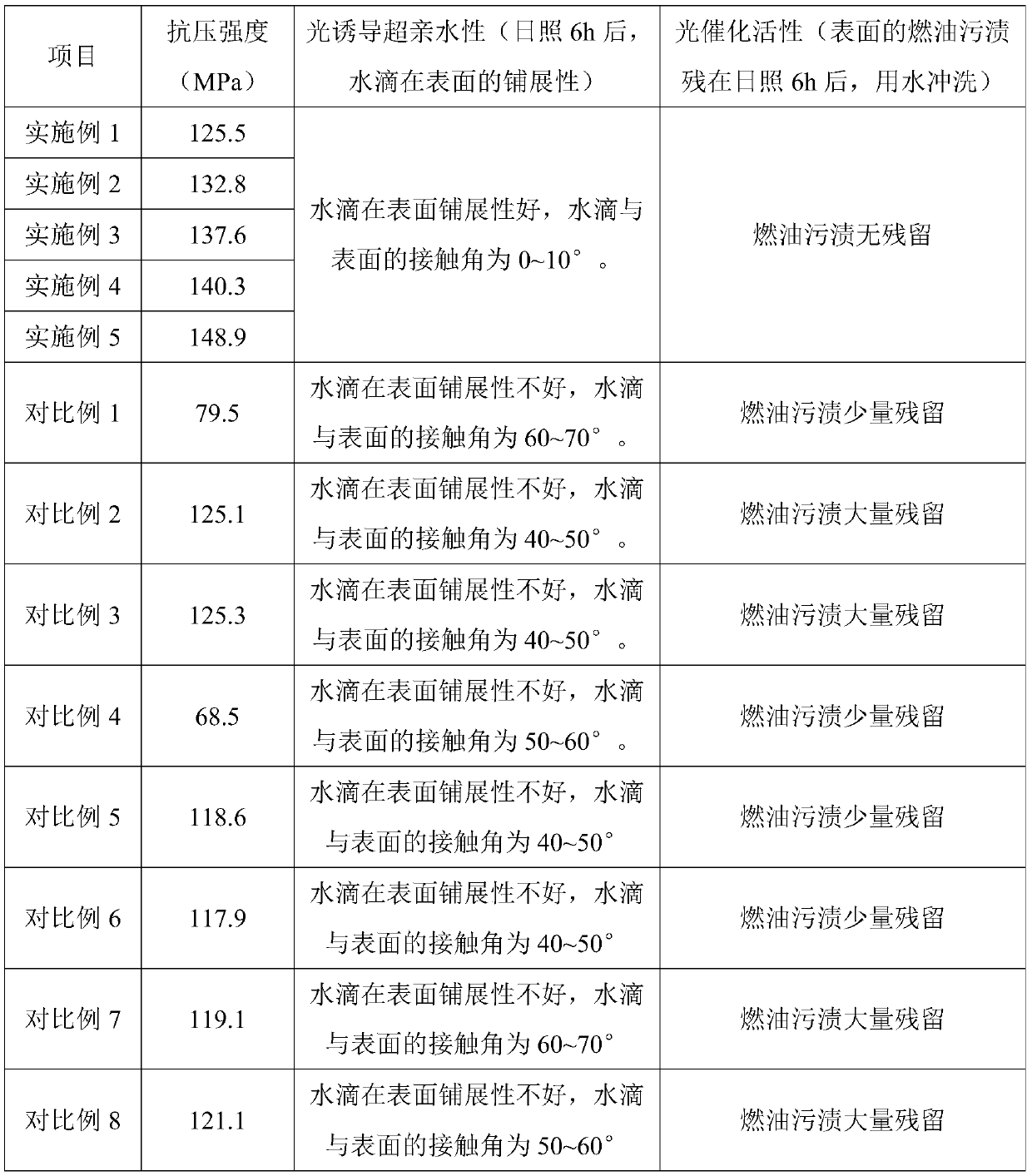

Examples

Embodiment 1

[0034] A self-cleaning artificial stone slab for outdoor use, which is prefabricated from ultra-high-performance mineral powder with a compressive strength of 100-150 MPa, and the ultra-high-performance mineral powder includes the following raw material components in parts by weight: mineral active powder 80 parts of body, 8 parts of titanium dioxide, 150 parts of self-cleaning aggregate, 4 parts of nano-silica, 0.5 parts of water-repellent agent, 10 parts of water, 2 parts of water-reducing agent, and 4 parts of pigment.

[0035] The mineral active powder is mainly composed of cement above 42.5 and mixed with one or more active powders of silica fume, mineral powder, glass beads, and zeolite powder. The mass ratio of the mineral active powder components is cement: silica fume : Mineral powder: Glass beads: Zeolite powder is 1:0.125:0.75:0.15:0.1.

[0036] The titanium dioxide is anatase titanium dioxide with a particle size of 10-1000nm. On the one hand, it uses its photocata...

Embodiment 2

[0050] Except that the formulation of the ultra-high performance mineral powder is different, other conditions are the same as in Example 1.

[0051] The ultra-high-performance mineral powder includes the following raw material components in parts by weight: 100 parts of mineral active powder, 13 parts of titanium dioxide, 220 parts of self-cleaning aggregate, 8 parts of nano-silica, 2 parts of water repellent, 5 parts of water, 4 parts of water reducing agent, 10 parts of pigment.

Embodiment 3

[0053] Except that the formulation of the ultra-high performance mineral powder is different, other conditions are the same as in Example 1.

[0054] The ultra-high-performance mineral powder includes the following raw material components in parts by weight: 85 parts of mineral active powder, 9.5 parts of titanium dioxide, 170 parts of self-cleaning aggregate, 5 parts of nano-silica, 0.9 part of water repellent, 11 parts of water, 2.5 parts of water reducer, 5.5 parts of pigment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com