Method for preparing co-permeation layer on surface of TC4 titanium alloy through boro-carbonization method

A boron carbide and titanium alloy technology, applied in metal material coating process, coating, solid diffusion coating and other directions, can solve the problems of poor wear resistance, low hardness, etc., to reduce production costs, improve surface hardness, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Preparation of borocarburizing:

[0044] S201 (preparation of infiltration agent): Precisely configure the carburizing agent according to the composition ratio, and use a planetary ball mill to grind for 30 minutes to make the composition of the boron carburizing agent uniform;

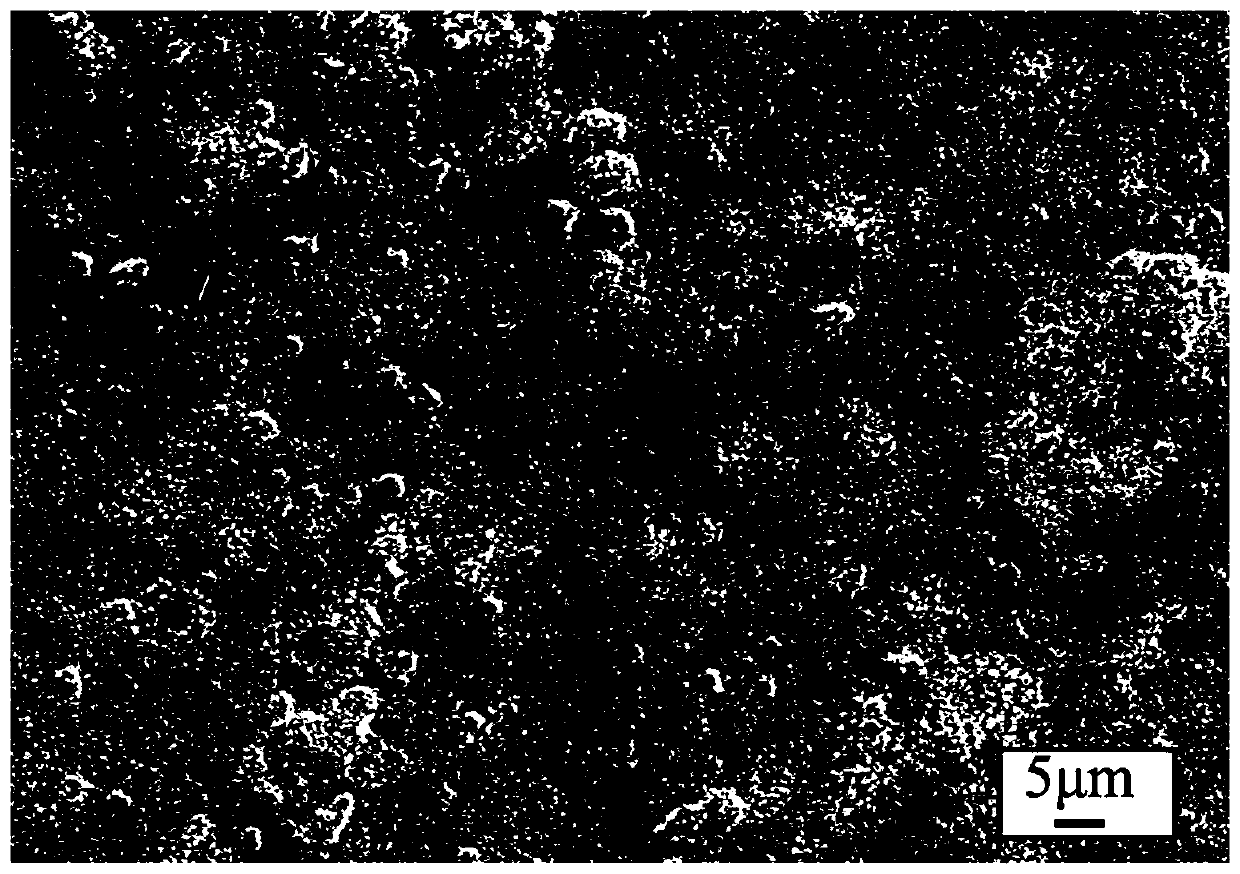

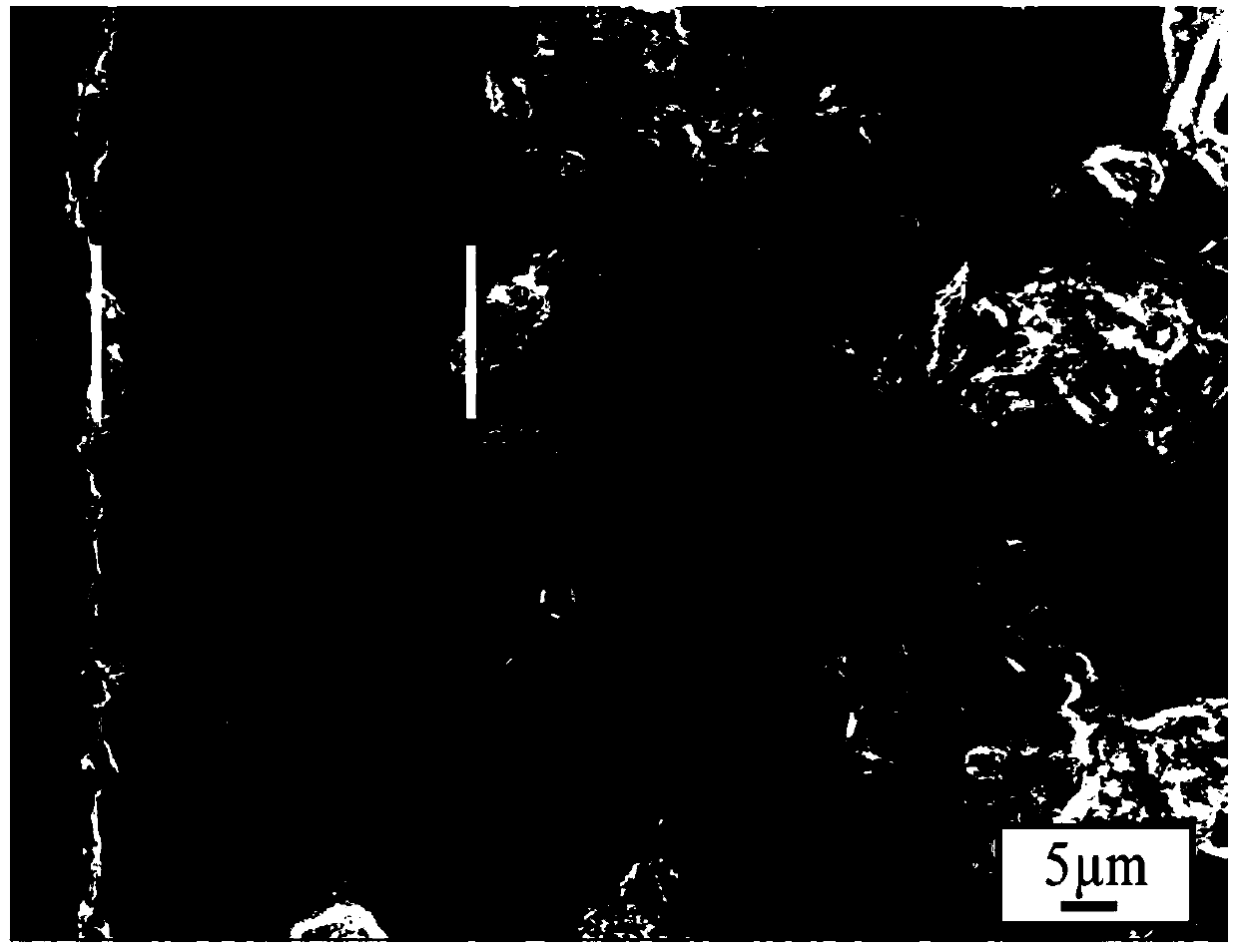

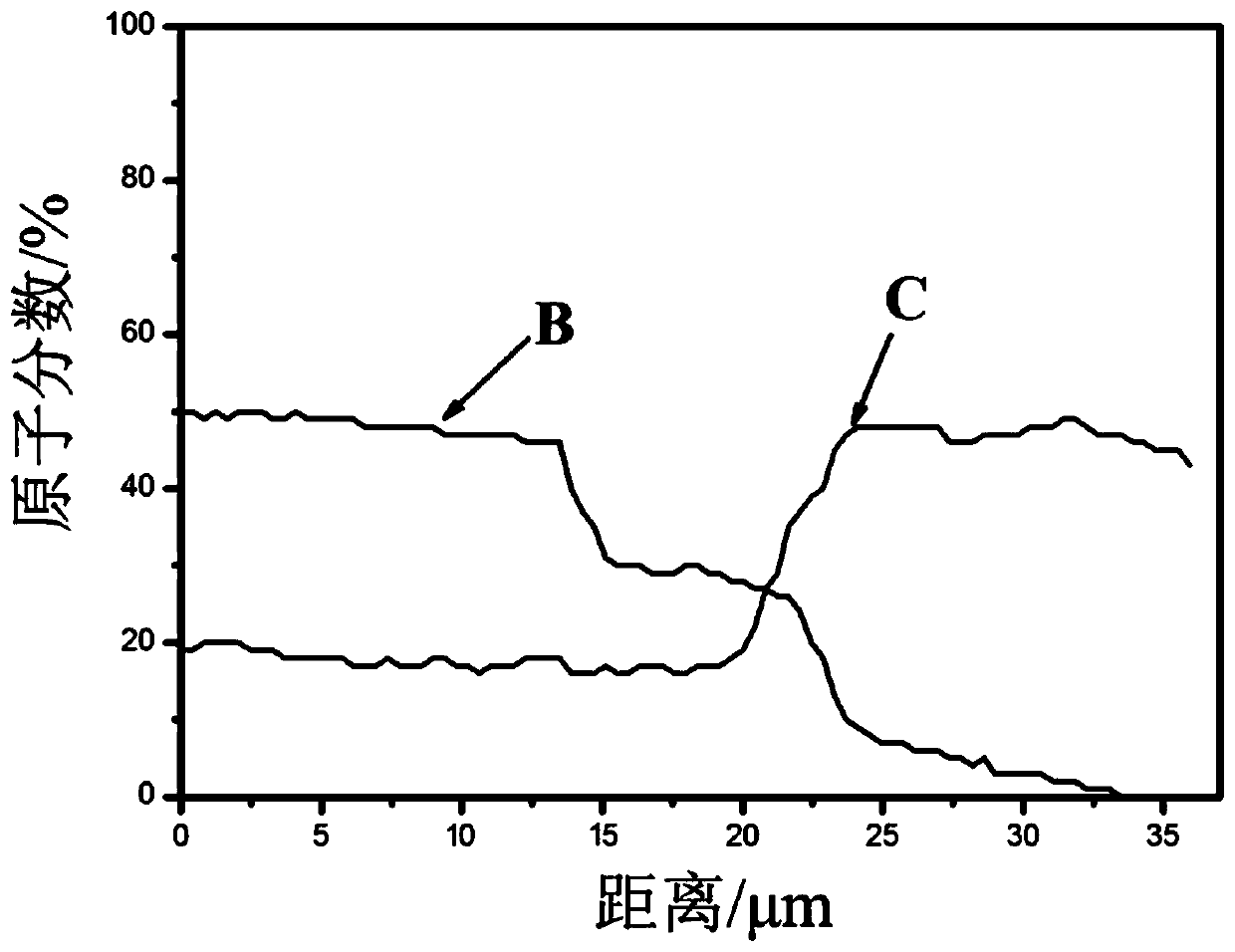

[0045] S202 (furnace heating up): Put the infiltrating agent after the grinding of the above configuration into the corundum ark, put the TC4 titanium alloy sample that has been pre-carburized into the infiltrating agent, cover it, and put it into the heating area of the tube furnace. Introduce argon gas into the tube furnace to ensure that the air is exhausted to form an argon atmosphere protection. After the argon atmosphere is stable, start heating to 850~1150℃ and keep it warm for 8~12h.

[0046] S203 (cooling and sampling): after the heat preservation is over. Cool to room temperature with the furnace, take out the sample, ultrasonically clean it for 10 minutes, and dry it for later use...

Embodiment 1

[0049] The invention provides a method for preparing a co-infiltration layer on the surface of a TC4 titanium alloy by boron-carburizing, comprising the following steps:

[0050] Carburizing pretreatment:

[0051] S101 (sample preparation): prepare a TC4 titanium alloy, and process it into a sample with a size of 15×15×4 mm by wire cutting. Then use 180#, 280#, 320#, 400#, 500#, 600#, 800# sandpaper to grind the substrate sample step by step, and then use a mechanical polishing machine to polish the polished sample. Until the surface becomes a mirror surface without obvious scratches, put it into a beaker containing absolute ethanol for ultrasonic cleaning for 10 minutes, and place it in an alcohol bottle for later use;

[0052] S102 (Furnace heating): Embed the dried TC4 sample in the carburizing agent and place it in the corundum ark with a cover to ensure that the sample will not have direct contact with the corundum ark, and place it in the heating area of the tube furn...

Embodiment 2

[0059] The invention provides a method for preparing a co-infiltration layer on the surface of a TC4 titanium alloy by boron-carburizing, comprising the following steps:

[0060] Carburizing pretreatment:

[0061] S101 (sample preparation): prepare a TC4 titanium alloy, and process it into a sample with a size of 15×15×4 mm by wire cutting. Then use 180#, 280#, 320#, 400#, 500#, 600#, 800# sandpaper to grind the substrate sample step by step, and then use a mechanical polishing machine to polish the polished sample. Until the surface becomes a mirror surface without obvious scratches, put it into a beaker containing absolute ethanol for ultrasonic cleaning for 10 minutes, and place it in an alcohol bottle for later use;

[0062] S102 (Furnace heating): Embed the dried TC4 sample in the carburizing agent and place it in the corundum ark with a cover to ensure that the sample will not have direct contact with the corundum ark, and place it in the heating area of the tube furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness value | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com