Preparation method of defect-containing WO3 photoelectrode

A photoelectrode and defect technology, applied in the direction of electrode, electrode shape/type, electrolysis process, etc., can solve the problems of high cost, complex preparation process, harsh reaction conditions, etc., and achieve the effect of low cost, simple process and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

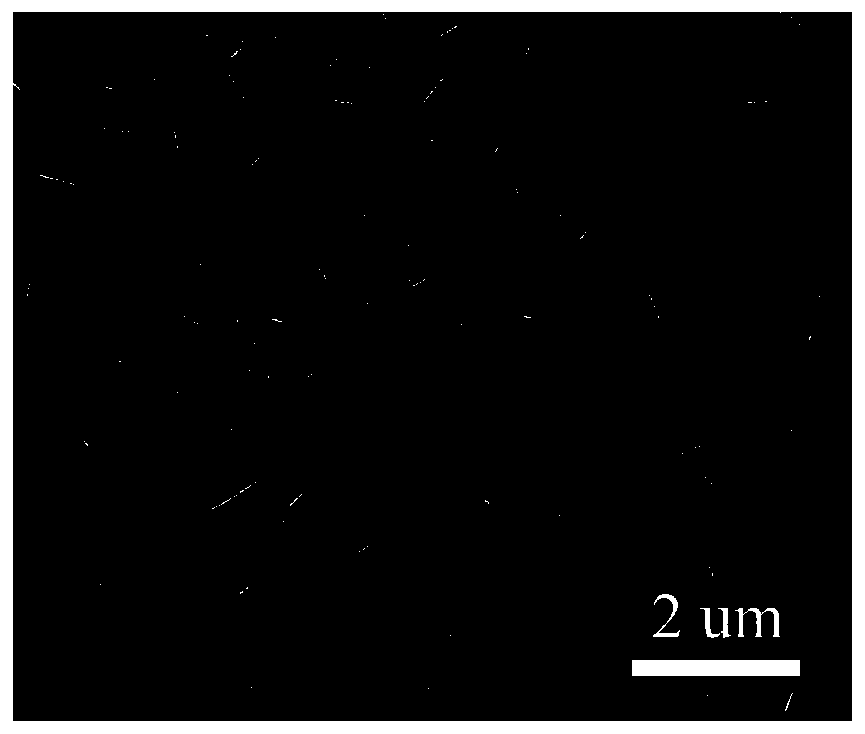

[0026] (1) WO 3 The preparation process of the photoelectrode is as follows: 3.3g of sodium tungstate was weighed and dissolved in 1000mL of deionized water, and stirred for 10 minutes to obtain a transparent and clear solution. Add 40 mL of HCl solution with a concentration of 5 mol / L to the above solution, stir for 10 minutes to obtain a yellow tungstic acid suspension, and then add 2.48 g of ammonium oxalate to obtain a transparent and clear solution. Put the cleaned FTO conductive glass with the conductive side down into the solution, and react in a water bath at 60°C for 8 hours to obtain bright yellow H 2 WO 4 electrode. The prepared H 2 WO 4 The electrode is placed in a muffle furnace and annealed at 500°C for 2 hours to obtain light yellow WO 3 electrode.

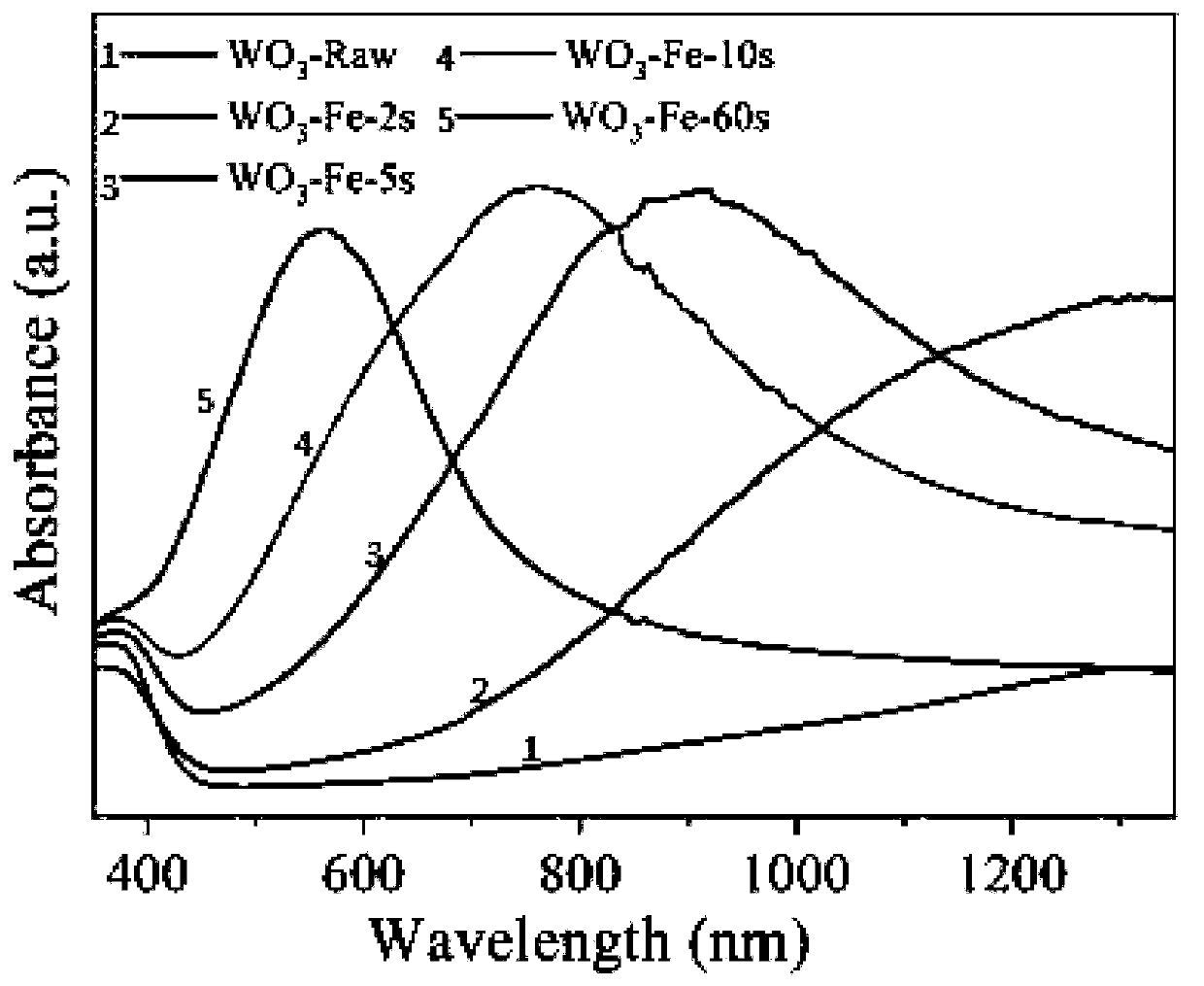

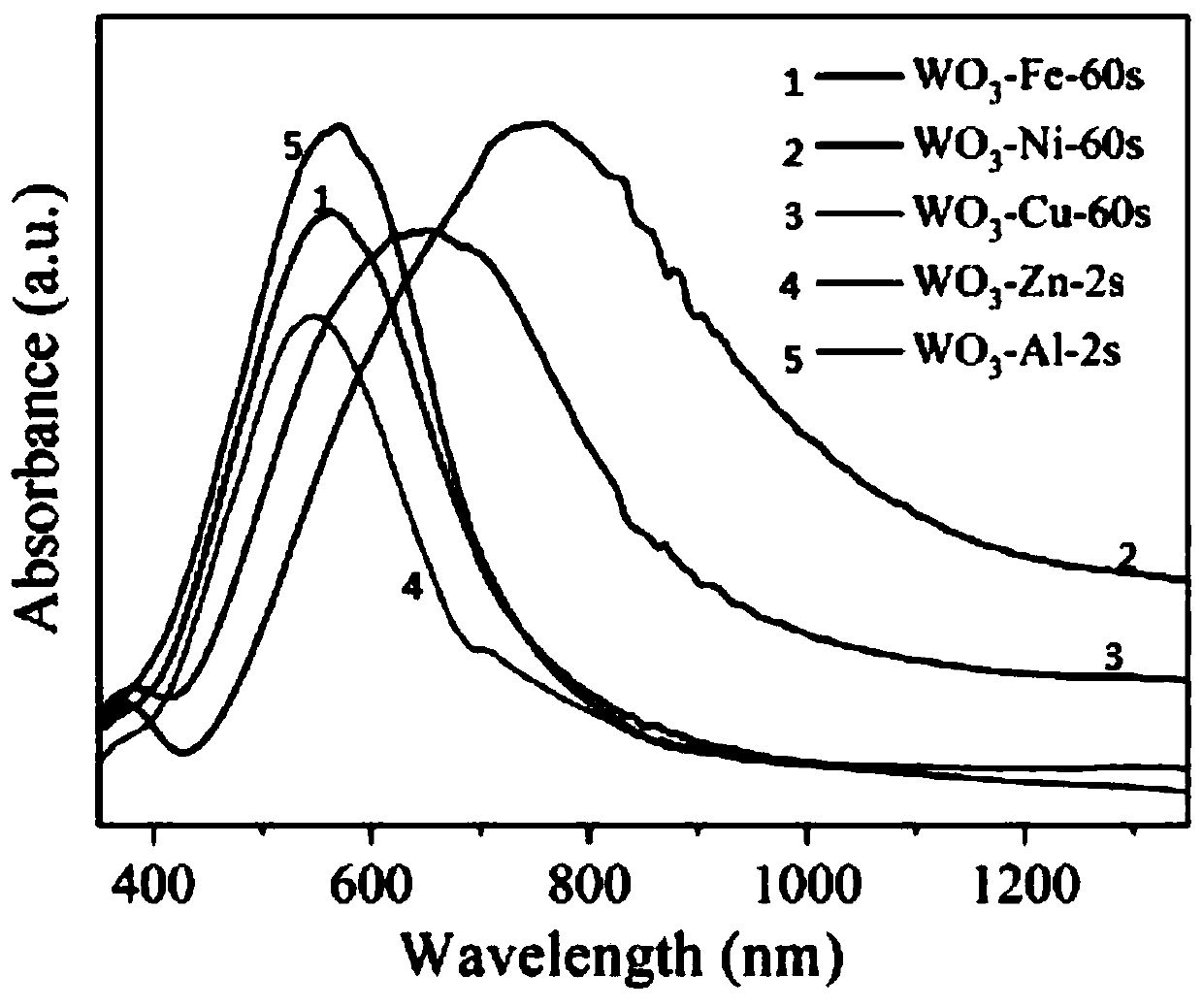

[0027] (2) Defect WO 3 The preparation process of the photoelectrode is as follows: the WO prepared in (1) 3 The electrode is connected to the Fe foil with a wire, and the WO 3 The electrode and Fe foil wer...

Embodiment 2

[0029] (1) WO 3The preparation process of the photoelectrode is as follows: Weigh 8.25g of sodium tungstate and dissolve it in 1000mL of deionized water, and stir for 10 minutes to obtain a transparent and clear solution. Add 100 mL of HCl solution with a concentration of 5 mol / L to the above solution, stir for 10 minutes to obtain a yellow tungstic acid suspension, and then add 6.2 g of ammonium oxalate to obtain a transparent and clear solution. Put the cleaned FTO conductive glass with the conductive side down into the solution, and react in a water bath at 60°C for 8 hours to obtain bright yellow H 2 WO 4 electrode. The prepared H 2 WO 4 The electrode is placed in a muffle furnace and annealed at 500°C for 2 hours to obtain light yellow WO 3 electrode.

[0030] (2) Defect WO 3 The preparation process of the photoelectrode is as follows: the WO prepared in (1) 3 The electrode is connected to the Fe foil with a wire, and the WO 3 The electrode and Fe foil were simul...

Embodiment 3

[0032] (1) WO 3 The preparation process of the photoelectrode is as follows: Weigh 16.5g of sodium tungstate and dissolve it in 1000mL of deionized water, and stir for 10 minutes to obtain a transparent and clear solution. Add 250mL of HCl solution with a concentration of 5mol / L to the above solution, stir for 10 minutes to obtain a yellow tungstic acid suspension, and then add 12.4g of ammonium oxalate to obtain a transparent and clear solution. Put the cleaned FTO conductive glass with the conductive side down into the solution, and react in a water bath at 60°C for 8 hours to obtain bright yellow H 2 WO 4 electrode. The prepared H 2 WO 4 The electrode is placed in a muffle furnace and annealed at 500°C for 2 hours to obtain light yellow WO 3 electrode.

[0033] (2) Defect WO 3 The preparation process of the photoelectrode is as follows: the WO prepared in (1) 3 The electrode is connected to the Fe foil with a wire, and the WO 3 The electrode and Fe foil were simult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com