Manufacturing method of nano silver wire transparent conductive film with customizable patterns

A technology of transparent conductive film and nano-silver wire, which is applied in the direction of equipment, circuits, and electrical components used to manufacture conductive/semiconductive layers, and can solve problems such as limited flexibility, affecting yield, and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Embodiment 1, preparation of bonding glue and flexible transparent optical glue

[0074] The preparation method of the polyurethane acrylic prepolymer used in the bonding adhesive and the flexible transparent optical adhesive of this embodiment is as follows:

[0075] (a) Dehydration of raw materials: PEG-1000, polyether triol polyoxypropylene triol-600, 1,6-hexamethylene diisocyanate and hydroxyethyl acrylate are subjected to high-temperature vacuum dehydration treatment. The treatment conditions are: The temperature is 100°C, the vacuum degree is 0.1MPa, and the time is 2h.

[0076] (b) Reaction of polyol and isocyanate: in N 2 Under a protective environment, add 5.5 mol of the above-mentioned dehydrated 1,6-hexamethylene diisocyanate into the flask, mechanically stir at a speed of 500 r / min, while slowly heating to 60°C, and then add 3.64 mol of the dehydrated The mixed solution of PEG-1000 and 0.91mol polyether trihydric alcohol polyoxypropylene triol-600 was adde...

Embodiment 2

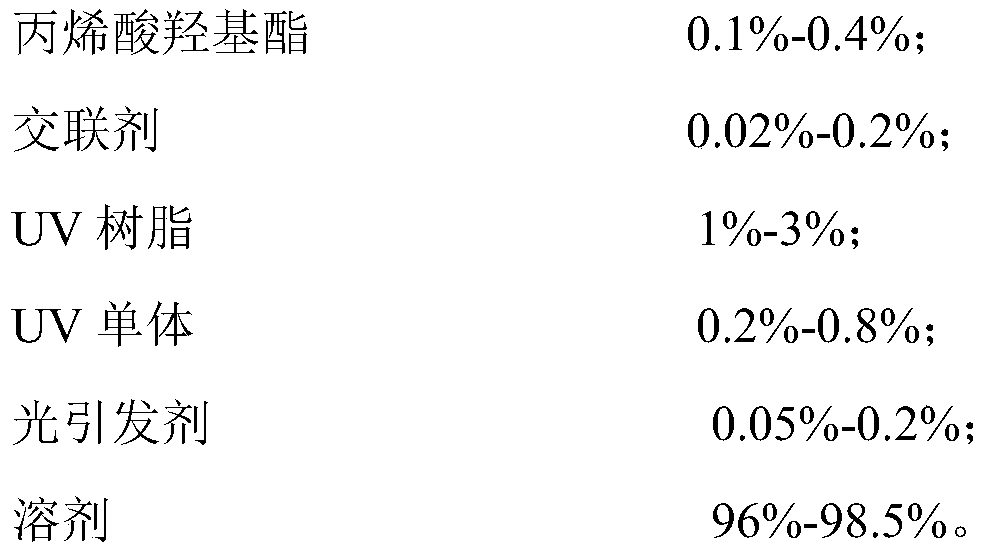

[0084] The preparation method of the coating liquid with UV irradiation viscosity-reducing function used in this embodiment is: under dust-free and yellow light environment, 972g solvent (ethyl acetate, butanol and cyclohexanone by mass ratio 1:1:1 mixture ), 20g UV resin (WDS-9500 and DSM2421 mixed at a mass ratio of 1:1), 4g UV monomer (trimethylolpropane triacrylate), and 2g hydroxyethyl acrylate were added to the dispersion tank in turn, at 1000r / min Speed mechanical stirring for 30min; then add 1g of photoinitiator (photoinitiator 184) and 1g of crosslinking agent (1,6-hexamethylene diisocyanate) in sequence, and continue to stir for 10min to obtain a UV-viscosity-reducing Coating solution.

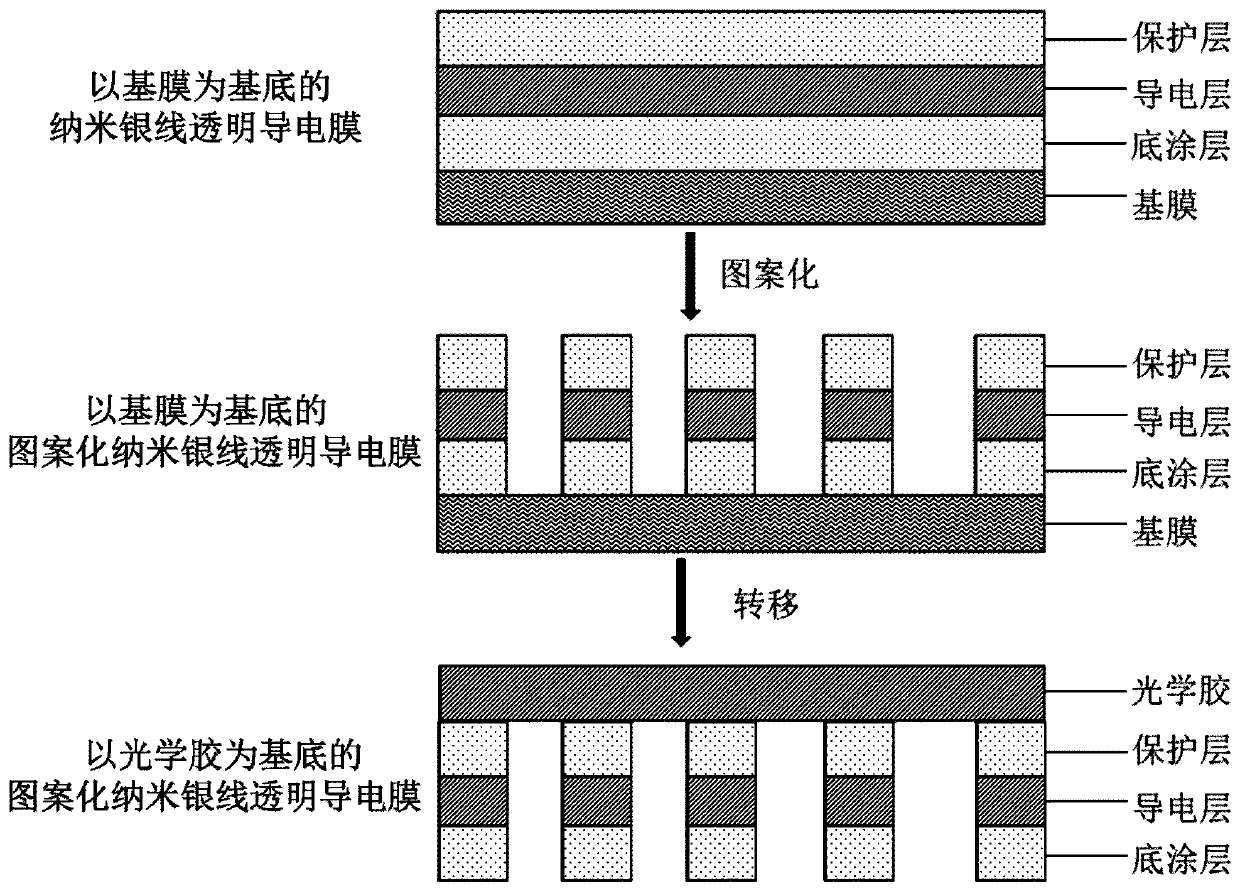

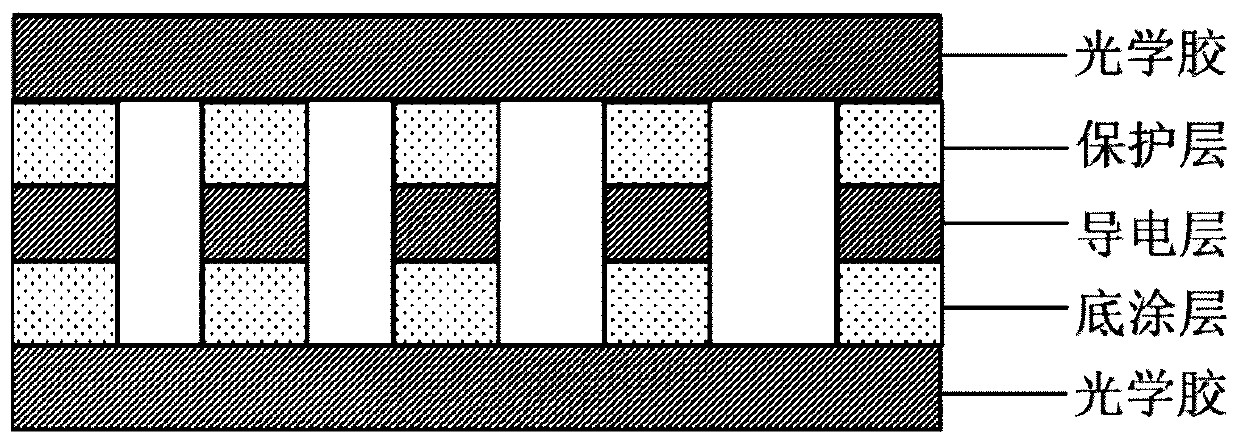

[0085] like figure 1 As shown, the present embodiment makes the nano-silver wire transparent conductive film with desired pattern according to the following steps:

[0086] Step 1, setting the nano-silver wire transparent conductive film based on the PET base film

[0087] 11. C...

Embodiment 3

[0098] In this embodiment, the nano-silver wire transparent conductive film with the required pattern is produced by the same method as in Example 2, the difference is only that the preparation method of the coating liquid with UV irradiation viscosity-reducing function used is: under dust-free and yellow light environment, 972g solvent (mixture of ethyl acetate, butanol and cyclohexanone in mass ratio 1:1:1), 20g UV resin (CN9013NS and CN9010 in mass ratio of 1:1), 4g UV monomer (trimethylol Propane triacrylate), 2g hydroxyethyl acrylate were added into the dispersing cylinder in turn, and mechanically stirred at a speed of 1000r / min for 30min; then 1g photoinitiator (photoinitiator 184) and 1g crosslinking agent (1,6-hexaethylene Methyl diisocyanate), and continue to stir for 10 minutes to obtain a coating liquid with UV irradiation viscosity-reducing function.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com