Round potted pool recirculating culture system

A technology of recirculating breeding and pools, applied in fish farming, application, animal husbandry, etc., can solve problems such as high operating costs, blockage of equipment sewage pipes, and large daily power consumption, so as to reduce cost input and increase added value , the effect of less land resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

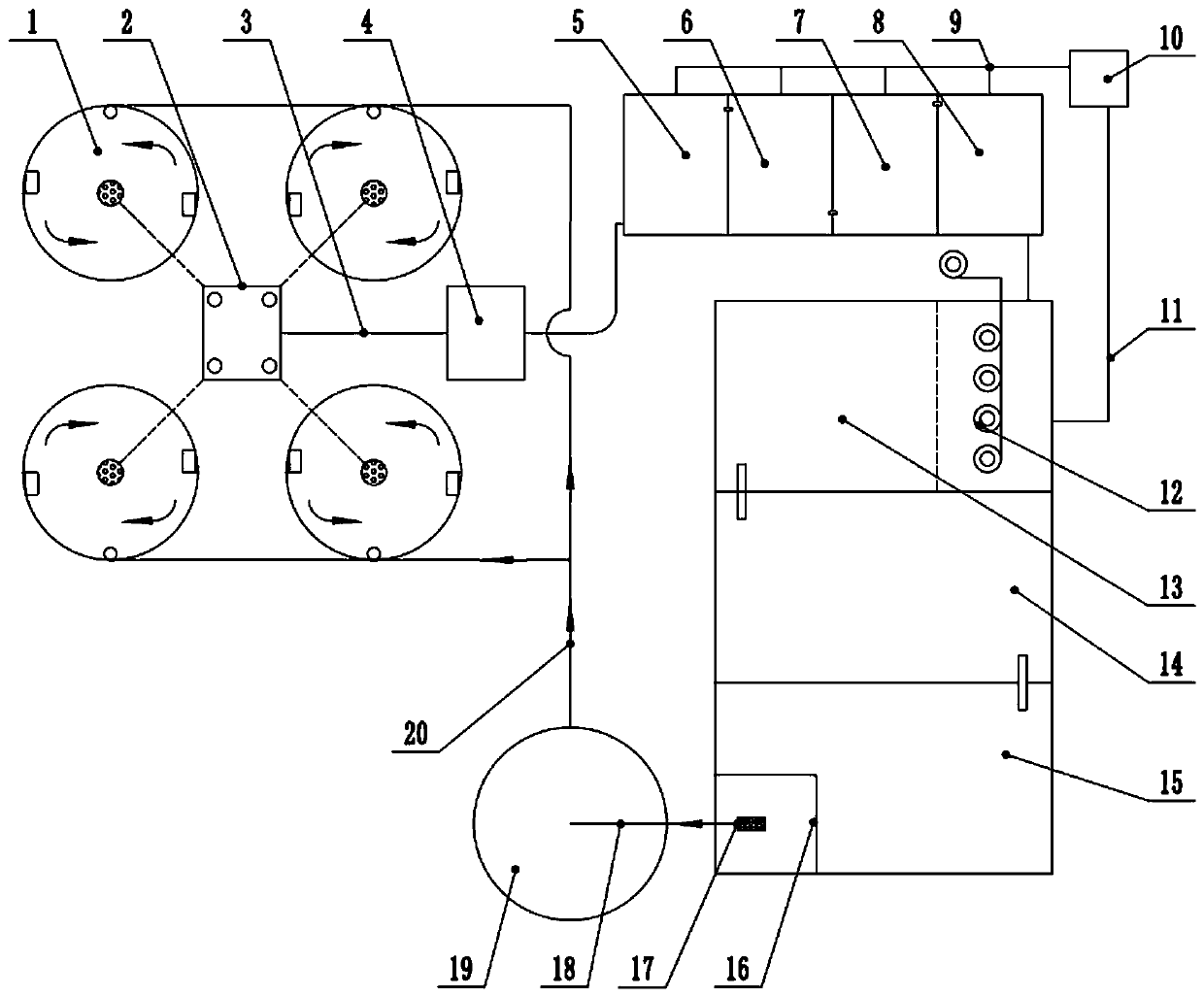

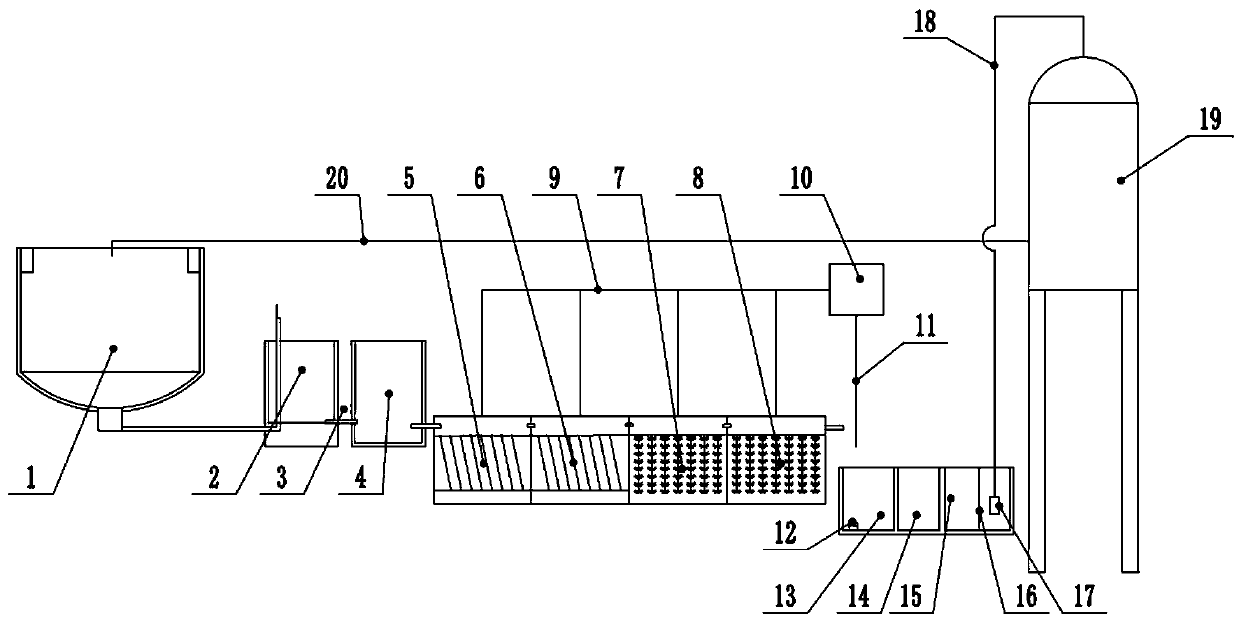

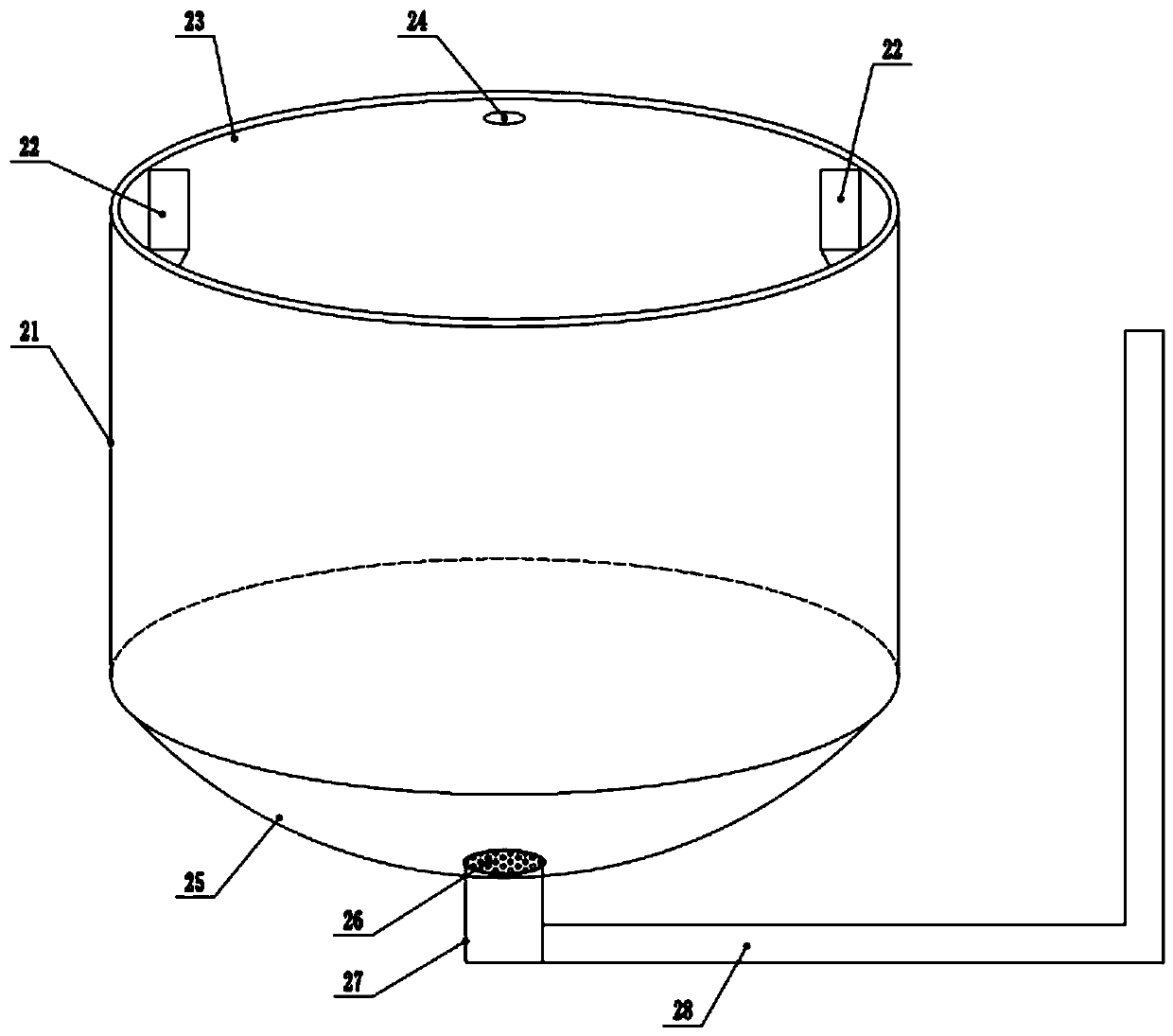

Embodiment 1

[0031] A kind of round pot bottom pool circulation culture system, it comprises round pot bottom pool 1, sewage well 2, water pipe 3, sedimentation well 4, sedimentation tank, purification pond and water storage tower 19, described round pot bottom pool 1 The bottom is connected to the sewage well 2, the sewage well 2 is connected to the sand sinking well 4 through the water pipe 3, the sand sinking well 4 is connected to the sedimentation tank through the pipeline, the sedimentation tank is connected to the purification pond through the pipeline, and the water discharged from the round pot bottom pool 1 passes through the sand sinking well 4 Filtration, sedimentation in the sedimentation tank, and purification in the purification pond are transported to the water storage tower 19 by the water pump 17 and the suction pipe 18, and then transported to the round bottom pool 1 by the water delivery pipe 20 after passing through the water storage tower 19 to realize circulation farm...

Embodiment 2

[0038] A kind of round pot bottom pool circulation culture system, it comprises round pot bottom pool 1, sewage well 2, water pipe 3, sedimentation well 4, sedimentation tank, purification pond and water storage tower 19, described round pot bottom pool 1 The bottom is connected to the sewage well 2, the sewage well 2 is connected to the sand sinking well 4 through the water pipe 3, the sand sinking well 4 is connected to the sedimentation tank through the pipeline, the sedimentation tank is connected to the purification pond through the pipeline, and the water discharged from the round pot bottom pool 1 passes through the sand sinking well 4 Filtration, sedimentation in the sedimentation tank, and purification in the purification pond are transported to the water storage tower 19 by the water pump 17 and the suction pipe 18, and then transported to the round bottom pool 1 by the water delivery pipe 20 after passing through the water storage tower 19 to realize circulation farm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com