Sustained-release sodium butyrate suitable for aquatic animals and preparation method of sustained-release sodium butyrate

A slow-release sodium butyrate and aquatic animal technology, which is applied in the molding or processing of animal feed, animal feed, application, etc., can solve the problems of short enzymatic digestion time, high content of unsaturated fatty acids, and incompatibility with the intestinal tract of aquatic animals, etc. problem, to achieve the effect of improving the utilization rate and shortening the enzymatic digestion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

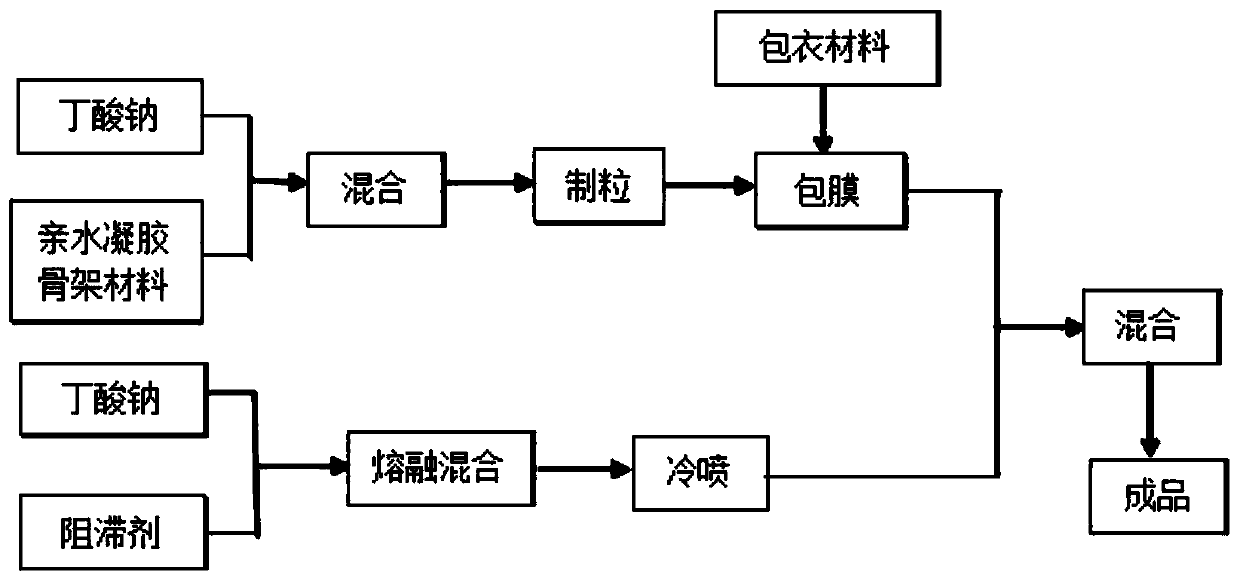

[0039] see figure 1 , a preparation method of slow-release sodium butyrate suitable for aquatic animals, comprising the following steps:

[0040] Preparation of water-soluble matrix sustained-release granules: First, mix sodium butyrate and hydrophilic gel matrix materials evenly to make preliminary granules, then mix and dissolve the film-forming materials and spray on the surface of the prepared granules to form a coating layer to obtain water-soluble Matrix slow-release granules;

[0041] Preparation of fat-soluble sustained-release granules: melt and mix the blocking agent and sodium butyrate, then perform cold-spray granulation to obtain fat-soluble sustained-release granules;

[0042] Mixing: Mix the water-soluble matrix sustained-release granules prepared above with the fat-soluble sustained-release granules evenly to obtain the sustained-release sodium butyrate suitable for aquatic animals.

Embodiment 1

[0044] A preparation method of slow-release sodium butyrate applicable to aquatic animals, the specific steps are as follows:

[0045] 1) In parts by weight, take the raw materials according to the following formula, and set aside:

[0046] Sodium butyrate: 30 parts

[0047] HPMC: 1 part

[0048] Sodium alginate: 15 parts

[0049] J-stearate: 35 parts

[0050] Acrylic resin No. Ⅳ: 10 parts

[0051] Polyethylene glycol: 4 parts

[0053] 2) Granulation: Mix 15 parts of sodium butyrate with hydrophilic gel skeleton material: 1 part of HPMC, 15 parts of sodium alginate, add 10-25 parts of water to prepare a soft material, and extrude in a granulator Made into soft strips and rounded into 300-500 micron preparatory particles in a spherical shot blasting machine. Then dry the prepared granules in a fluidized dryer with an inlet air temperature of 105-110°C for 30-50 minutes to ensure that the material is dry while reducing energy consumption.

...

Embodiment 2

[0058] A preparation method of slow-release sodium butyrate applicable to aquatic animals, the specific steps are as follows:

[0059] 1) In parts by weight, take the raw materials according to the following formula and set aside.

[0060] Sodium butyrate: 50 parts

[0061] HPMC: 1 part

[0062] Gelatin: 10 parts

[0063] J-stearate: 25 parts

[0064] Acrylic resin No. Ⅳ: 7 parts

[0065] Polyethylene glycol: 4 parts

[0067] 2) Granulation: mix 25 parts of sodium butyrate with hydrophilic gel skeleton material: 1 part of HPMC, 9 parts of gelatin, add 10-25 parts of water to prepare a soft material, and extrude it in a granulator Soft strips are rounded into 300-500 micron preparatory particles in a spherical shot blasting machine. Then dry the prepared granules in a fluidized dryer with an inlet air temperature of 105-110°C for 30-50 minutes to ensure that the material is dry while reducing energy consumption.

[0068] 3) Coating: Mix 7 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com