Formula and feeding method of concentrate for beef cattle in fattening period

A feeding method and fattening period technology, applied in the field of beef cattle breeding, can solve the problems of waste of feed resources, insufficient nutritional needs and low cost performance, and achieve the effects of eliminating the waste of feed nutrition, shortening the slaughtering cycle and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

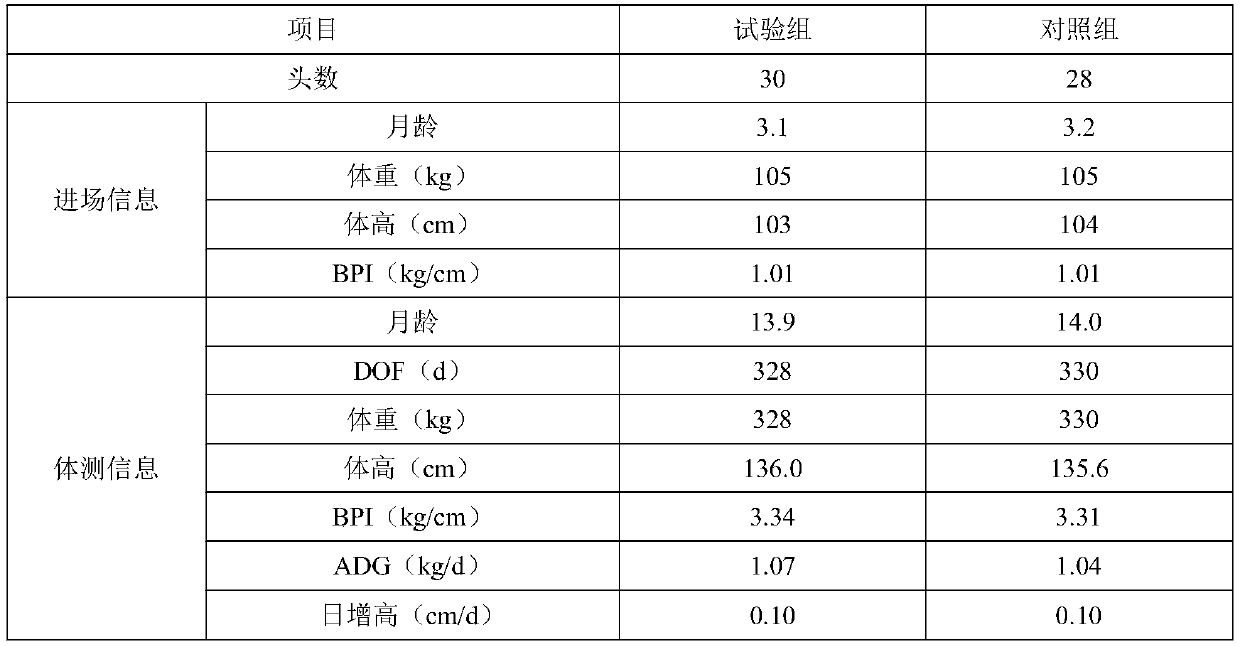

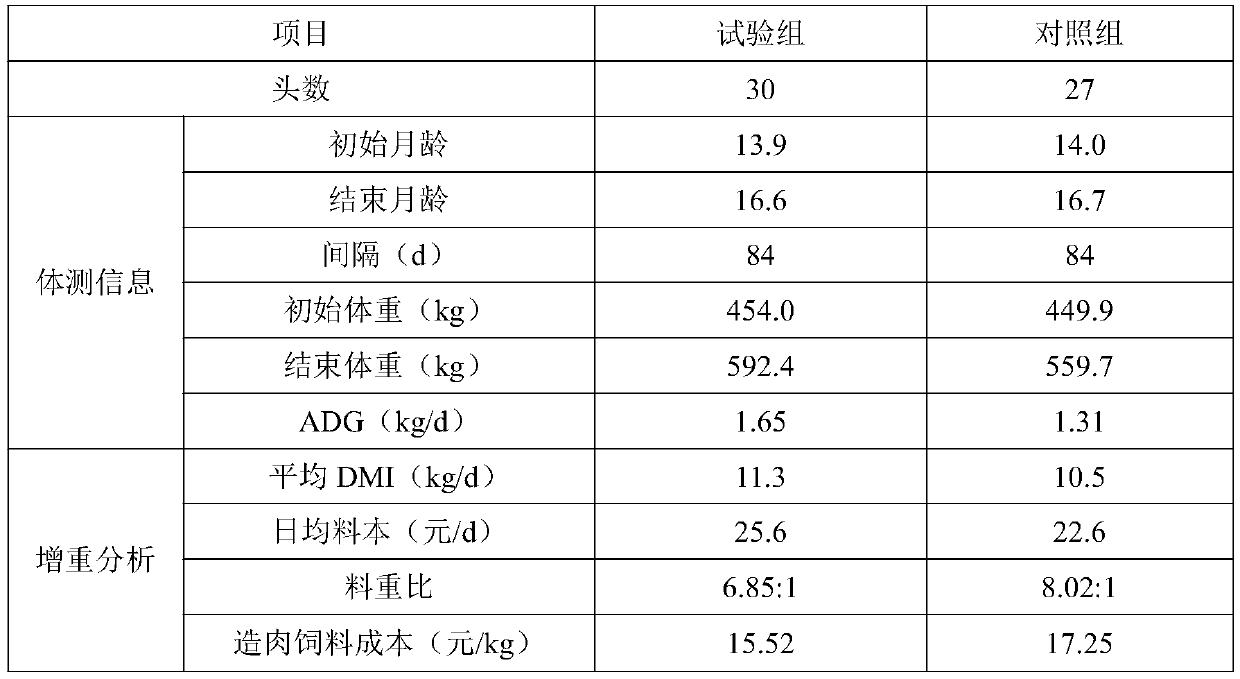

Embodiment 1

[0024] This example provides a concentrate formula for beef cattle fattening period, which includes the following components by weight percentage: 51% corn, 7.0% bran, 4.7% soybean meal, 2.4% rapeseed meal, 9.2% corn DDGS, spray Corn bran 18%, starch gelatinized urea 1.14%, stone powder 0.56%, premix 6%.

[0025] In the concentrate formula for beef cattle fattening period in this embodiment, the addition amount of each raw material in each ton of the premix is: vitamin A 0.21kg; vitamin D 0.04kg; vitamin E 5.0kg; ferrous sulfate 10kg; sulfuric acid 1.9kg copper; 4.5kg manganese sulfate; 6.3kg zinc sulfate; 2.4kg 1% iodine; 0.7kg 1% cobalt; 0.5kg 1% selenium; 36kg calcium hydrogen phosphate; 220kg stone powder; 78kg sodium chloride; Magnesium oxide 90kg; Potassium chloride 84kg; Zeolite powder 330.45kg.

Embodiment 2

[0027] This example provides a concentrate formula for beef cattle fattening period, which includes the following components by weight percentage: 66% corn, 4.6% bran, 3.4% soybean meal, 1.8% rapeseed meal, 6.4% corn DDGS, spray Corn bran 12%, starch gelatinized urea 0.8%, stone powder 0.6%, premix 4.4%.

[0028] In the concentrate formula for beef cattle fattening period in this embodiment, the addition amount of each raw material in each ton of the premix is: vitamin A 0.32kg; vitamin D 0.04kg; vitamin E 4.0kg; ferrous sulfate 10kg; sulfuric acid 2.9kg copper; 4.5kg manganese sulfate; 4.2kg zinc sulfate; 2.4kg 1% iodine; 0.8kg 1% cobalt; 0.7kg 1% selenium; 30kg calcium hydrogen phosphate; 180kg stone powder; 56.14kg sodium chloride; ; Magnesium oxide 60kg; Potassium chloride 56kg; Zeolite powder 492kg.

Embodiment 3

[0030] This embodiment provides a concentrate formula for beef cattle fattening period, which includes the following components by weight percentage: corn corn 54.8%, bran 6.4%, soybean meal 4.5%, rapeseed meal 2.2%, corn DDGS 9.2%, spray Corn bran 15.7%, starch gelatinized urea 1.1%, stone powder 0.6%, premix 5.5%.

[0031] In the concentrate formula for beef cattle fattening period in this embodiment, the addition amounts of each raw material in the premix per ton are: vitamin A 0.24kg; vitamin D 0.03kg; vitamin E 4.6kg; ferrous sulfate 10.5kg; 2.6kg copper sulfate; 3.3kg manganese sulfate; 4.5kg zinc sulfate; 2.8kg 1% iodine; 0.8kg 1% cobalt; 0.55kg 1% selenium; 30kg calcium hydrogen phosphate; 195kg stone powder; 60kg sodium chloride; 100kg sodium bicarbonate ; Magnesium oxide 68.5kg; Potassium chloride 64kg; Zeolite powder 452.58kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com