High-fiber spicy gluten and preparation method thereof

A technology of spicy and spicy strips, which is applied in the field of high-fiber spicy strips and its preparation, can solve the problems of lack of high-quality protein and dietary fiber, and health hazards of children and adolescents, achieve strong fragrance, increase intake, and promote the dissolution of ingredients Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

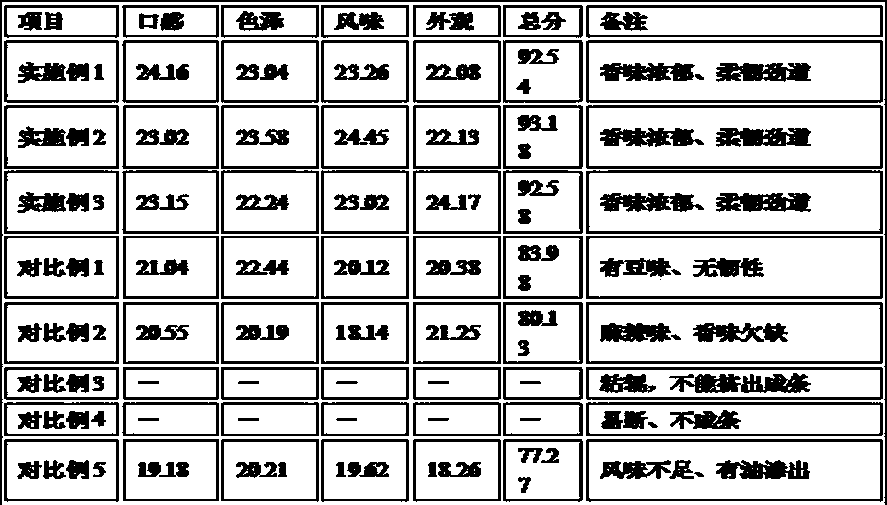

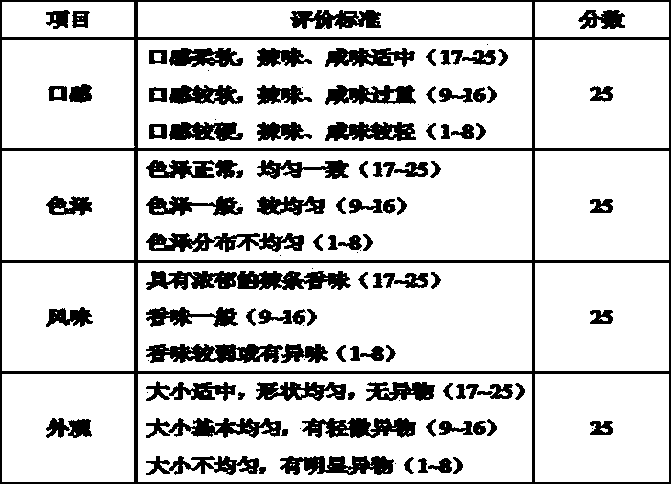

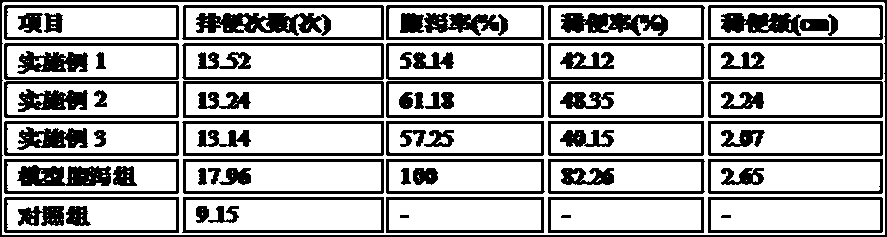

Examples

Embodiment 1

[0029] A high-fiber spicy noodle, prepared from the following parts by weight: 70 parts of high-gluten wheat flour, 30 parts of peeled okara powder, 40 parts of eggs, 6 parts of salt, 3 parts of sugar, 4 parts of monosodium glutamate, 1 part of casein, 40 parts flavoring agent, 20 parts water;

[0030] The seasoning agent is 2 parts of pepper powder, 2 parts of pepper powder, 8 parts of chili powder, 3 parts of star anise, and 25 parts of edible oil.

[0031] The method for preparing the high-fiber spicy noodles includes the following steps:

[0032] (1) First crush the peeled okara to 150 mesh;

[0033] (2) First, fully mix the peeled okara powder, eggs, salt, monosodium glutamate, sugar, casein, and water, then add 80% flour, stir until flocculent, and finally add the remaining 20% flour, and mix quickly;

[0034] (3) Pour the mixture into the extruder within 5 minutes, extrude and expand at high temperature, and then cut into strips to obtain the high-fiber spicy strips; the proce...

Embodiment 2

[0038] A high-fiber spicy noodle prepared from the following parts by weight: 80 parts high-gluten wheat flour, 20 parts dehulled okara powder, 50 parts egg, 4 parts salt, 5 parts sugar, 2 parts MSG, 3 parts casein, 55 parts of flavoring agent, 15 parts of water;

[0039] The seasoning agent is 4 parts of pepper powder, 4 parts of pepper powder, 10 parts of chili powder, 2 parts of star anise, and 35 parts of edible oil.

[0040] The method for preparing the high-fiber spicy noodles includes the following steps:

[0041] (1) First crush the peeled okara to 150 mesh;

[0042] (2) First, fully mix the peeled okara powder, eggs, salt, monosodium glutamate, sugar, casein, and water, then add 80% flour, stir until flocculent, and finally add the remaining 20% flour, and mix quickly;

[0043] (3) Pour the mixture into the extruder within 5 minutes, extrude and expand at high temperature, and then cut into strips to obtain the first high-fiber spicy strip; the process parameters of the extr...

Embodiment 3

[0047] A high-fiber spicy noodle prepared from the following parts by weight: 75 parts of high-gluten wheat flour, 25 parts of peeled okara powder, 45 parts of eggs, 5 parts of salt, 4 parts of sugar, 3 parts of MSG, 2 parts of casein, 50 parts of flavoring agent, 17 parts of water;

[0048] The seasoning agent is 3 parts of pepper powder, 3 parts of pepper powder, 9 parts of chili powder, 2 parts of star anise, and 33 parts of edible oil.

[0049] The method for preparing the high-fiber spicy noodles includes the following steps:

[0050] (1) First crush the peeled okara;

[0051] (2) First, fully mix the peeled okara powder, eggs, salt, monosodium glutamate, sugar, casein, and water, then add 80% flour, stir until flocculent, and finally add the remaining 20% flour, and mix quickly;

[0052] (3) Pour the mixture into the extruder within 5 minutes, extrude and expand at high temperature, and obtain the first high-fiber spicy strip after cutting; the process parameter of the extruder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com