Flat-panel CT machine

A technology of flat-panel and flat-panel detectors, which is applied in medical science, equipment for radiological diagnosis, and diagnosis. Integrity without missing, the effect of real data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

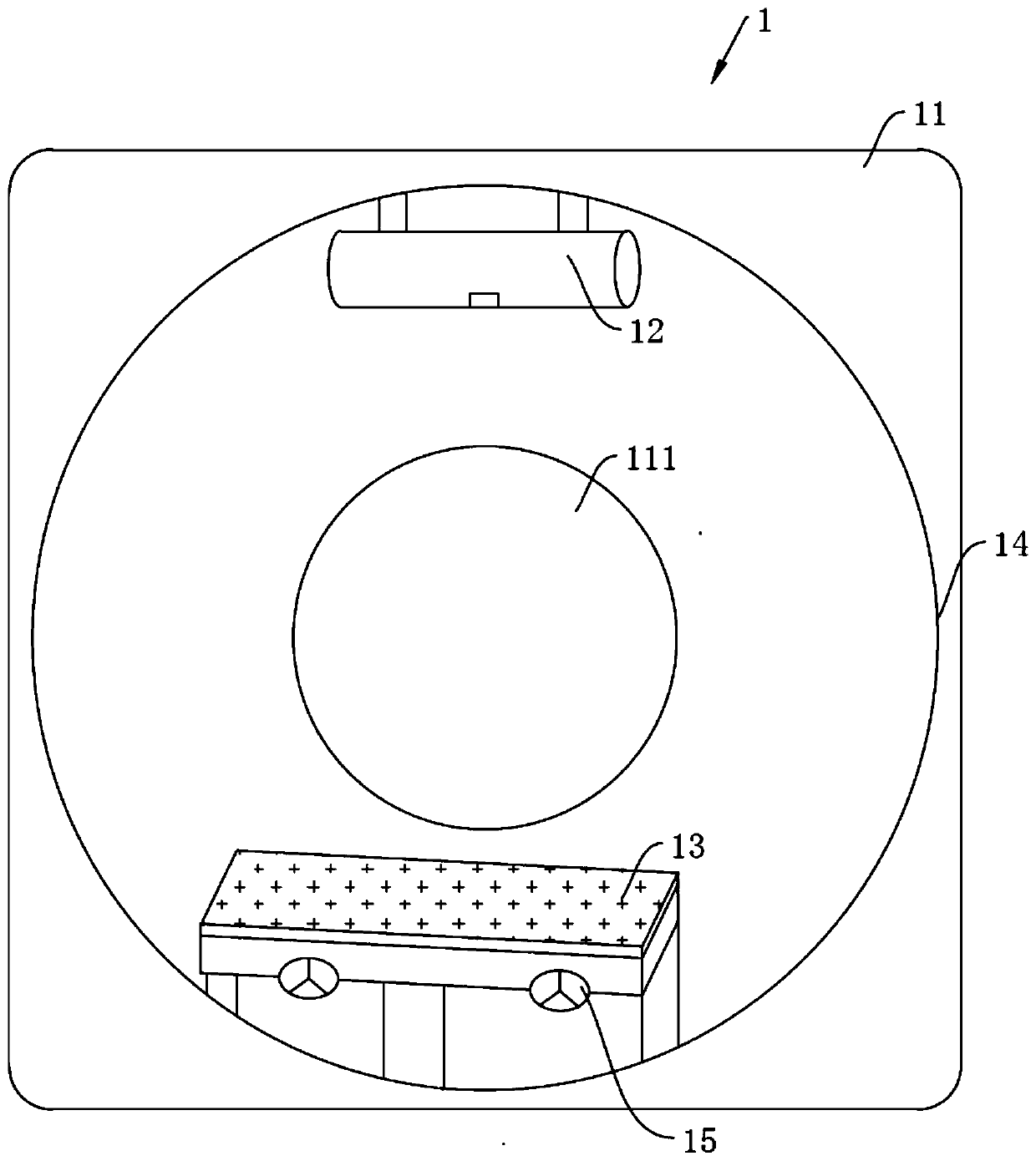

[0045] Such as figure 1 As shown, this embodiment provides a scanning frame 1 of a flat-panel CT machine, including a frame 11 , a radiation emitter 12 , a flat-panel detector 13 , a rotating device 14 and a cooling device 15 .

[0046] An inner hole 111 is formed on the frame 11 , and the radiation emitter 12 and the flat panel detector 13 are relatively arranged in the rotating device 14 and can be driven by the rotating device 14 to move along the axis of the inner hole 111 on a circle.

[0047] In this embodiment, the flat-panel CT machine adopts a 360° scanning mode, and the general structure of the scanning frame 1 is similar to that of the existing third-generation CT machine. In other embodiments, the flat-panel CT machine can also adopt a 180° scanning mode. At this time, its scanning frame 1 can be made into various C-arm structures in addition to a structure similar to that of a traditional CT machine.

[0048] In this embodiment, the scanning frame 1 is the main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com