Iodine-starch aerogel and preparation method and application thereof

An aerogel and starch technology, applied in the field of aerogel, can solve problems such as poor stability of available iodine, and achieve the effects of excellent antibacterial properties, good biocompatibility and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

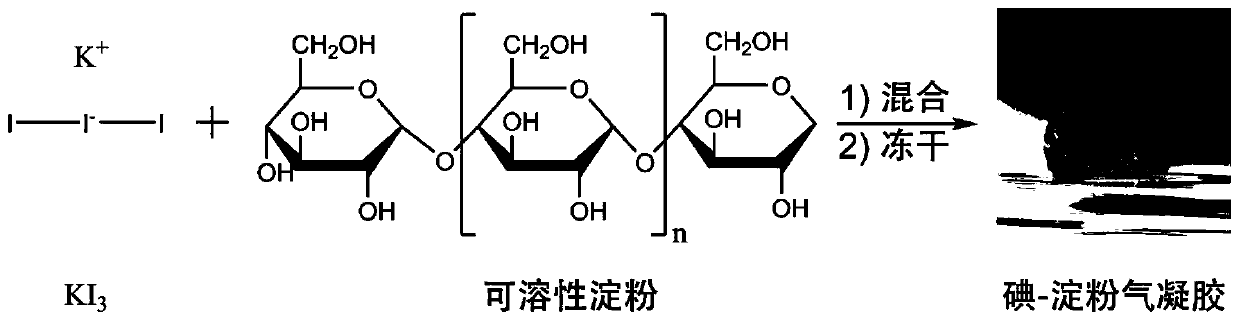

[0037] The preparation of iodine-starch airgel comprises the following steps:

[0038] (1) Mix potassium iodide and iodine element according to the mass ratio of 2:1, add appropriate amount of water to make the iodine concentration 15mg mL –1 , sonicate until all solids are completely dissolved;

[0039] (2) Weigh soluble starch (the molecular weight distribution range is 800–6000), add appropriate amount of water, heat and stir until all solids are completely dissolved, so that the concentration of soluble starch is 30mg mL –1 , naturally cooled to room temperature;

[0040] (3) According to the mass ratio of iodine to starch 1:50, add the solution in (1) to the soluble starch solution obtained in step (2), mix well and take an appropriate amount of liquid in a 96-well plate (200 μL / well), 24-well plate (2mL / well) and 6-well plates (5mL / well), freeze overnight at -80°C, freeze-dry and remove from the above mold to obtain three different sizes of iodine-starch aerogels.

[...

Embodiment 2

[0043] The water dissolution of iodine-starch airgel comprises the following steps:

[0044] Take an appropriate amount of water in any container, add an appropriate volume of iodine-starch airgel to obtain an iodine-starch solution. Available iodine concentration is 10μg mL –1 The UV-Vis absorption spectrum of the iodine-starch solution is shown in Figure 4 .

Embodiment 3

[0046]After storing for a certain period of time, the mensuration of available iodine content in iodine-starch solution, Lugol's iodine solution and povidone-iodine solution comprises the following steps:

[0047] (1) Prepare 3 mL of available iodine to be 50 μg mL –1 Lugol's iodine solution, povidone iodine solution, and iodine-starch solution are stored in centrifuge tubes respectively (all solutions are protected from light);

[0048] (2) Measure the ultraviolet-visible absorption spectra of the above three groups of solutions every day.

[0049] (3) Utilize the ultraviolet-visible absorption spectrum to measure the absorbance at 350nm place to calculate the relative content of remaining available iodine in the solution: available iodine relative content=Abs 350 (day n) / Abs 350 (Day 0)*100%.

[0050] The change curves of the effective iodine concentration of the three iodine-containing fungicides during a one-week storage period are as follows: Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com