Method for preparing high-purity copper chloride dehydrate by regulating and controlling copper-containing sludge through SiO2

A technology of copper chloride dihydrate, copper sludge, applied in copper chloride, copper halide, nanotechnology for materials and surface science, etc., can solve secondary pollution, high energy consumption, and poor purity of copper chloride. Advanced problems, to achieve the effect of saving usage, short process and saving reaction raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

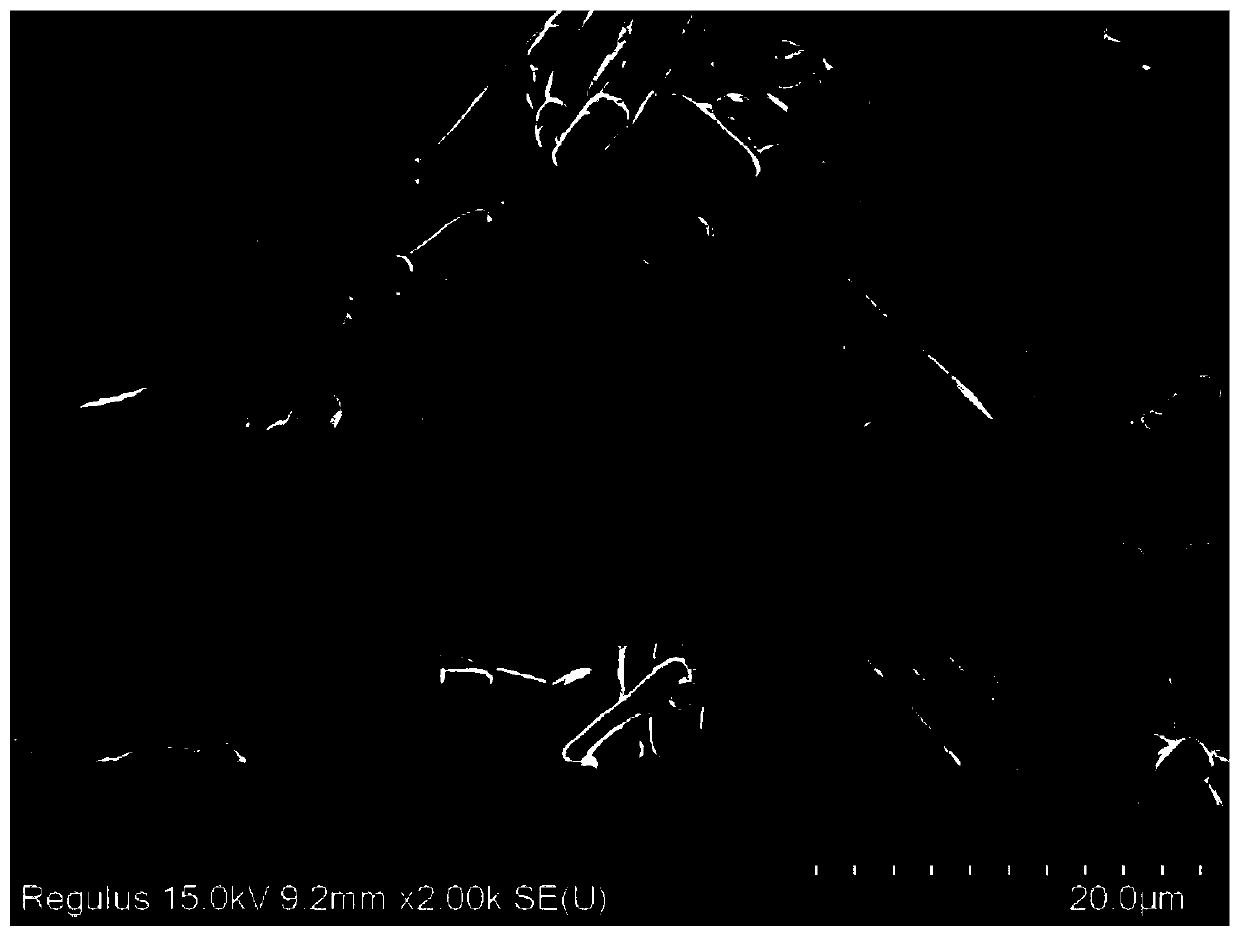

Image

Examples

Embodiment 1

[0028] (1) Place copper-containing sludge in an oven, dry at 105°C for 12 hours, grind, and pass through a 100-mesh sieve. Get the copper-containing sludge after 2g drying, add the concentrated hydrochloric acid of 3.0ml 36wt.% and 0.2g SiO 2 , stir well.

[0029] (2) Put the evenly stirred mixture in a tube furnace (the tube furnace has a built-in quartz tube, the air inlet and the gas outlet are respectively connected to the two ends of the quartz tube, the middle part of the quartz tube is the heating area, and the two ends are the low-temperature condensation area ; the gas outlet is connected to the gas washing bottle for tail gas absorption), in an air atmosphere with a flow rate of 6m / min, the temperature is raised to 700°C for 120min at a heating rate of 10°C / min, and the product CuCl is recovered in the low-temperature condensation zone of the tube furnace after cooling 2 2H 2 O, the recovery efficiency of copper is calculated to be 86.62.%.

Embodiment 2

[0031] (1) Place the copper-containing sludge in an oven, dry at 105°C for 10 hours, grind, and pass through a 100-mesh sieve. Get the copper-containing sludge after 2g drying, add the concentrated hydrochloric acid of 3.0ml 36wt.% and the SiO of 0.2g 2 , stir well.

[0032] (2) Put the evenly stirred mixture in a tube furnace (the tube furnace has a built-in quartz tube, the air inlet and the gas outlet are respectively connected to the two ends of the quartz tube, the middle part of the quartz tube is the heating area, and the two ends are the low-temperature condensation area ; the gas outlet is connected to the gas washing bottle for tail gas absorption), in an air atmosphere with a flow rate of 5m / min, the temperature is raised to 800°C for 60min at a heating rate of 10°C / min, and the product CuCl is recovered in the low-temperature condensation zone of the tube furnace after cooling 2 2H 2 O, the recovery efficiency of copper is calculated to be 96.80%, and its purity ...

Embodiment 3

[0035] (1) Place the copper-containing sludge in an oven, dry at 105°C for 10 hours, grind, and pass through a 100-mesh sieve. Get the copper-containing sludge after 4g drying, add the concentrated hydrochloric acid of 4.0ml 36wt.% and the SiO of 0.4g 2 , stir well.

[0036](2) Put the evenly stirred mixture in a tube furnace (the tube furnace has a built-in quartz tube, the air inlet and the gas outlet are respectively connected to the two ends of the quartz tube, the middle part of the quartz tube is the heating area, and the two ends are the low-temperature condensation area ; The gas outlet is connected to the gas washing bottle for tail gas absorption), and the temperature is raised to 800°C at a heating rate of 10°C / min under an air atmosphere with a flow rate of 6m / min. After being roasted for 120min, the product CuCl is recovered in the low-temperature condensation zone of the tube furnace 2 2H 2 O, the recovery efficiency of copper is calculated to be 95.20%, and it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com