Carbon dot fluorescent probe, and preparation method and application thereof

A carbon dot fluorescence and probe technology, which is applied in the field of organic small molecule fluorescent probes, can solve the problems of not being able to prevent iron ion corrosion well, and the experience cycle cannot be well matched, and achieve the effect of high selectivity detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

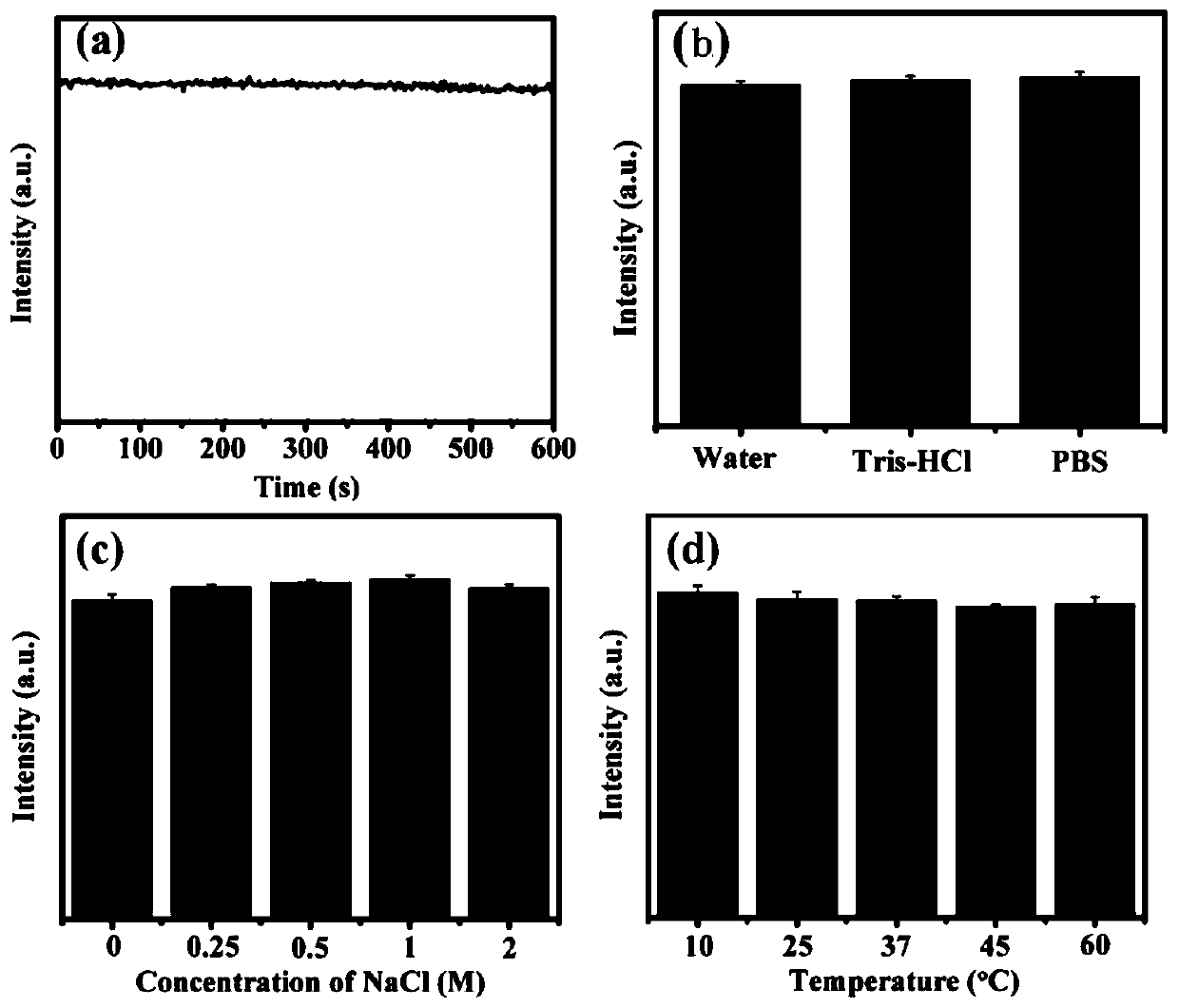

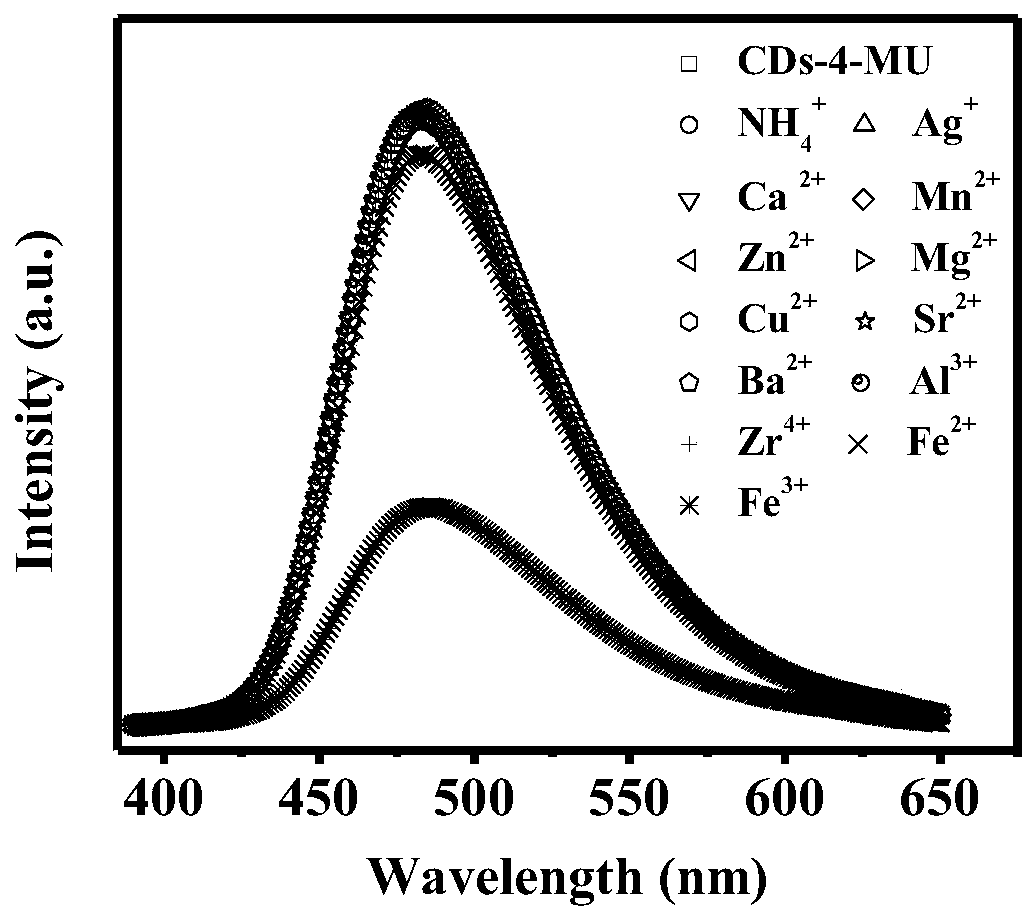

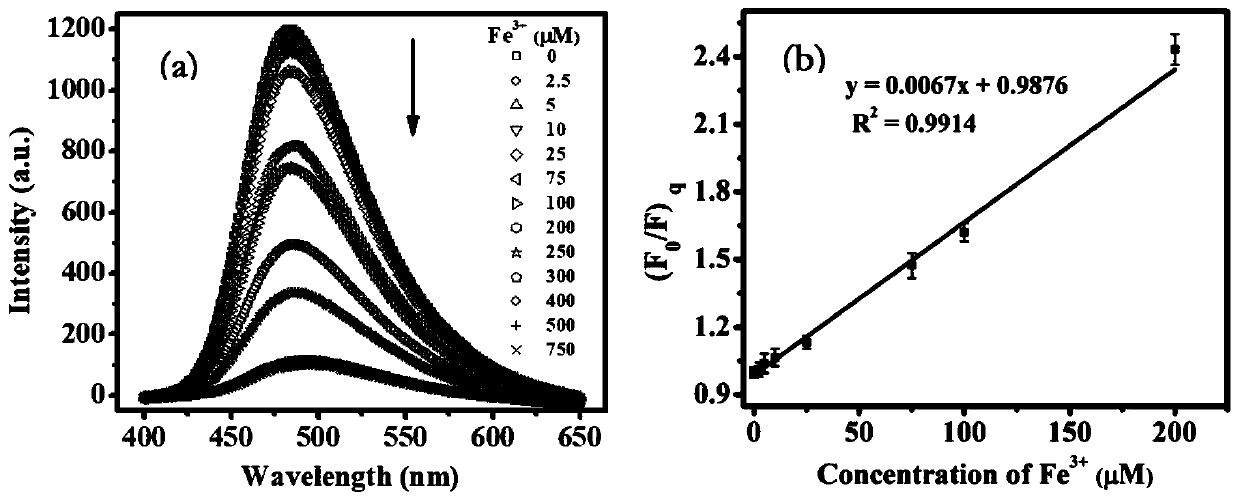

Method used

Image

Examples

Embodiment 1

[0020] Disperse 0.25 mmol of 4-methylumbelliferone in a solution containing 10 mL of ultrapure water and 0.25 mmol of D-arginine under gentle stirring. The mixture was transferred into a 50ml stainless steel autoclave lined with polytetrafluoroethylene, and the temperature of the autoclave was heated to 180°C and maintained for 12h. After naturally cooling to room temperature, the resulting suspension was centrifuged at a speed of 10,000 rpm for 5min to remove Large particles, and then the supernatant is filtered through a 0.22μm water membrane to further remove large particles completely. Finally, the crude solution was diluted with 10 ml of ultrapure water, and dialyzed in a cellulose ester film bag (molecular weight cut-off 200 Da) for 2 hours to obtain a purified product. After lyophilization, the yellow-brown powder was collected and redissolved in ultrapure water as a stock solution at a concentration of 0.5 mg / mL (called CDs-4-MU).

Embodiment 2

[0022] 0.5 mmol of 4-methylumbelliferone was dispersed under gentle stirring in a solution containing 20 mL of ultrapure water and 0.5 mmol of D-arginine. The mixture was transferred into a 100ml stainless steel autoclave lined with polytetrafluoroethylene, and the temperature of the autoclave was heated to 190°C and kept for 14h. After naturally cooling to room temperature, the resulting suspension was centrifuged at a speed of 20,000 rpm for 5min to remove Large particles, and then the supernatant is filtered through a 0.22μm water membrane to further remove large particles completely. Finally, the crude solution was diluted with 20 ml of ultrapure water, and dialyzed with stirring in a cellulose ester film bag (molecular weight cut-off 200 Da) for 2 hours to obtain a purified product. After lyophilization, the yellow-brown powder was collected and redissolved in ultrapure water as a stock solution at a concentration of 0.5 mg / mL (called CDs-4-MU).

Embodiment 3

[0024] 1 mmol of 4-methylumbelliferone was dispersed under gentle stirring in a solution containing 40 mL of ultrapure water and 1 mmol of D-arginine. The mixture was moved into a 200ml stainless steel autoclave lined with polytetrafluoroethylene, the temperature of the autoclave was heated to 200°C and kept for 15h, after cooling to room temperature naturally, the resulting suspension was centrifuged at a speed of 15000 rpm for 5min, Remove large particles, and then the supernatant is filtered through a 0.22 μm water membrane to further completely remove large particles. Finally, the crude solution was diluted with 40 ml of ultrapure water, and dialyzed with stirring in a cellulose ester film bag (molecular weight cut-off 200 Da) for 2 hours to obtain a purified product. After lyophilization, the yellow-brown powder was collected and redissolved in ultrapure water as a stock solution at a concentration of 0.5 mg / mL (called CDs-4-MU).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com