LiMnxOy-C three-dimensional nanosheet array as well as preparation method and application thereof

A three-dimensional nano-array technology, applied in the field of LiMnxOy@C three-dimensional nanosheet array material and preparation, can solve the problems of uneven thickness and reduced cycle performance, and achieve the effects of uniform morphology, high specific capacity, and low environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

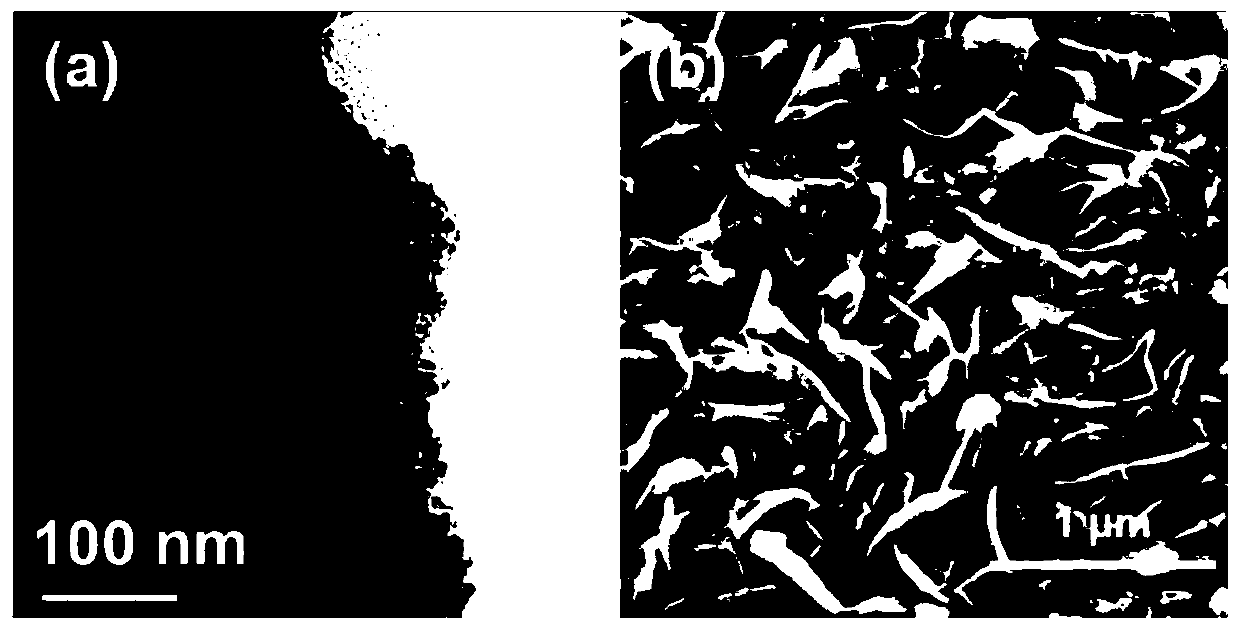

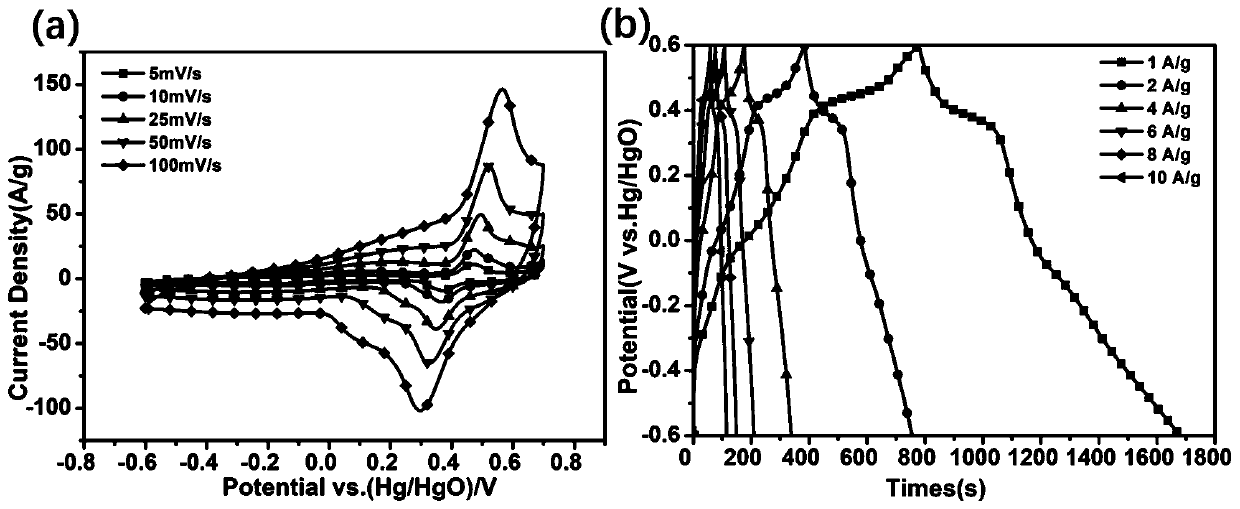

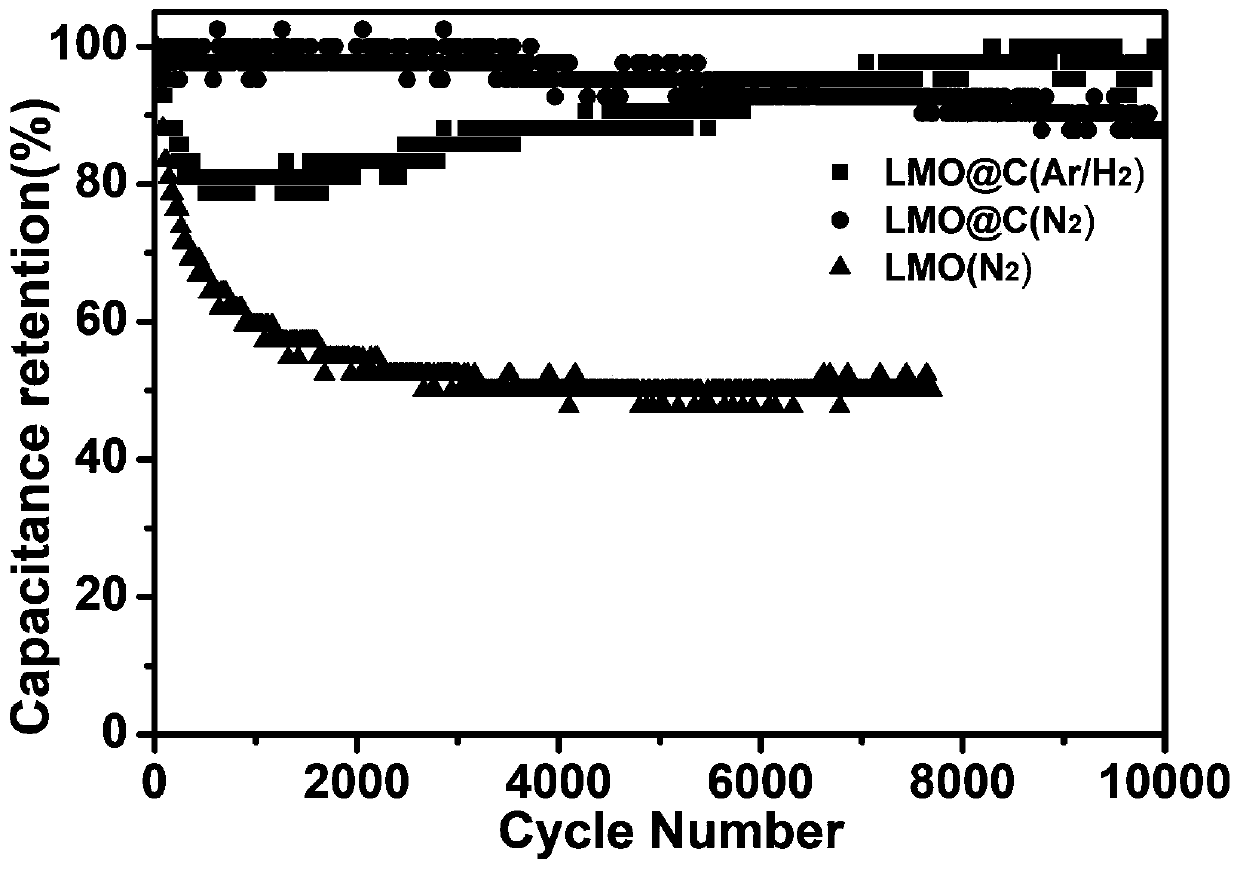

[0024] 0.7353g Mn(CH 3 COO) 2 and 0.42612 g of Na 2 SO 4 Dissolve in 30ml deionized water, stir magnetically for 5 minutes to fully dissolve. Next, place a piece of 1×1cm 2 The nickel foam is used as the working electrode, the Pt sheet is used as the counter electrode, and the saturated calomel electrode is used as the reference electrode. In the prepared solution, cyclic voltammetry electrodeposition is first carried out, the potential interval is 0.5-0.8V, and the deposition time is 30s. Then conduct constant voltage electrodeposition, the deposition potential is 0.7V, the deposition time is 30s, wash, dry and anneal for 2h under nitrogen at 200°C to obtain the precursor. Put the obtained precursor into 30ml to dissolve 0.03776g LiOH·H 2 O aqueous solution in a beaker, then transfer the precursor and the solution to a polytetrafluoroethylene reactor, and react at 200°C for 24h. After the reaction, wash and dry. The obtained sample was soaked in 0.02M glucose aqueous s...

Embodiment 2

[0030] 0.7353g Mn(CH 3 COO) 2 and 0.42612 g of Na 2 SO 4 Dissolve in 30ml deionized water, stir magnetically for 5 minutes to fully dissolve. Next, place a piece of 1x1cm 2 The foamed nickel was used as the working electrode, the Pt sheet was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode. In the prepared solution, cyclic voltammetry electrodeposition was first carried out, the potential interval was 0.6-0.9V, and the deposition time was 60s. Then conduct constant voltage electrodeposition, the deposition potential is 1V, the deposition time is 40s, washed, dried and annealed under nitrogen at 150°C for 1h to obtain the precursor. Put the obtained precursor into a 30ml beaker in which 0.03776g of LiOH·H2O aqueous solution was dissolved, then transfer the precursor and the solution to a polytetrafluoroethylene reactor, and react at 190°C for 18h. After the reaction, wash and dry. The obtained sample was soaked in 0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com