Hollow carbon rod, preparation method and application thereof and die head used in preparation process

A hollow, carbon rod technology, applied in other household appliances, electrodes of primary batteries, applications, etc., can solve the problems of poor battery discharge capacity consistency, damage to the positive carbon package structure, and lack of strength of carbon rods, reducing micro Short-circuit phenomenon, uniform compaction density, and avoid the effect of falling powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Preparation method of hollow carbon rod:

[0083] (1) Add polytetrafluoroethylene emulsion and isopropanol with a solid content of 60% into the solvent stirring tank of the mixer, and stir for 10 minutes at a frequency of 10 Hz to obtain a mixed solution;

[0084] (II) Add acetylene black into the mixer, add the mixed solution obtained in step (I) during the mixing process, and stir for 10 minutes to obtain a mixed slurry. In the mixed slurry, acetylene black, polytetrafluoroethylene emulsion and isopropyl The mass ratio of alcohol is 1:0.1:2;

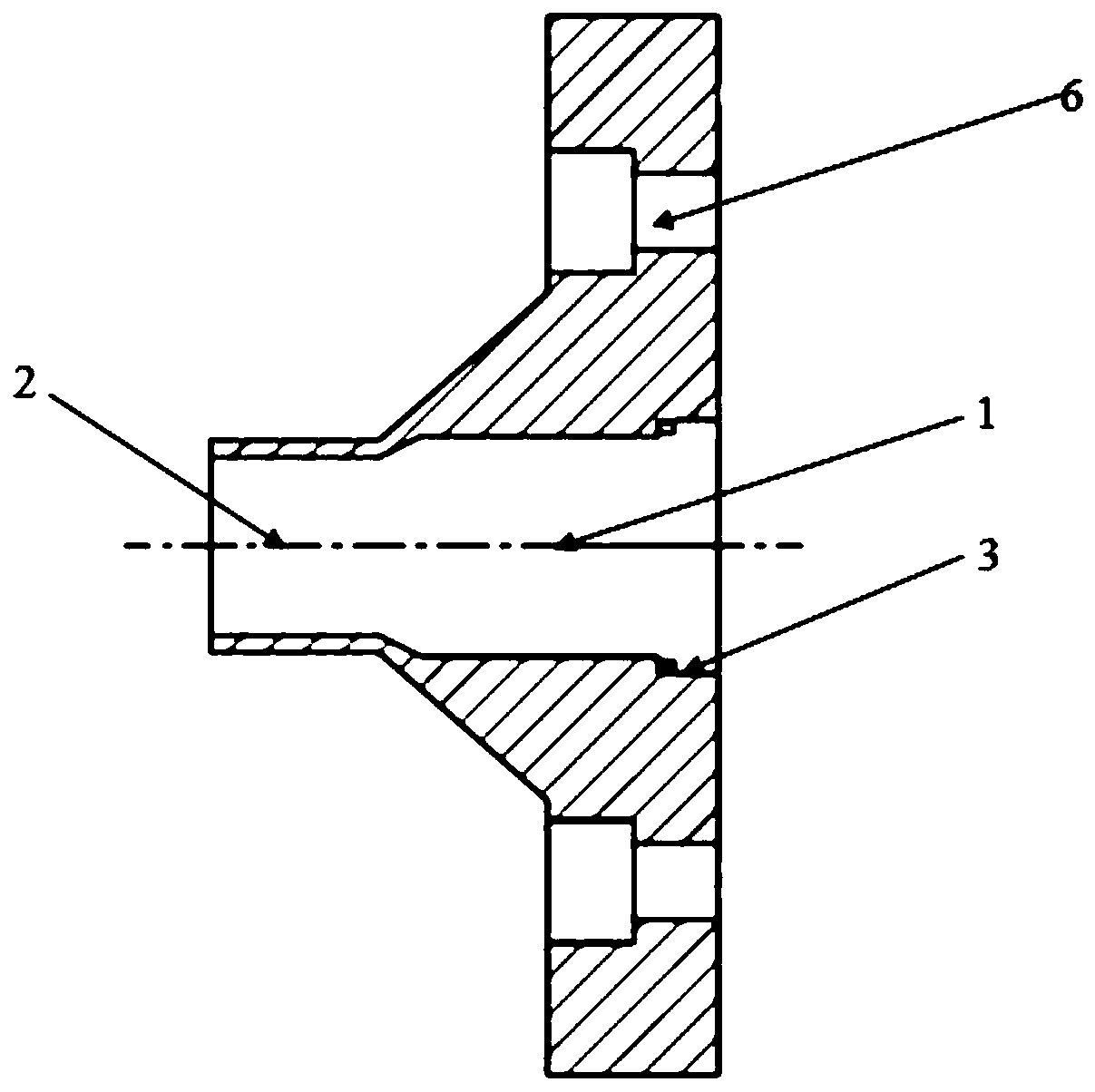

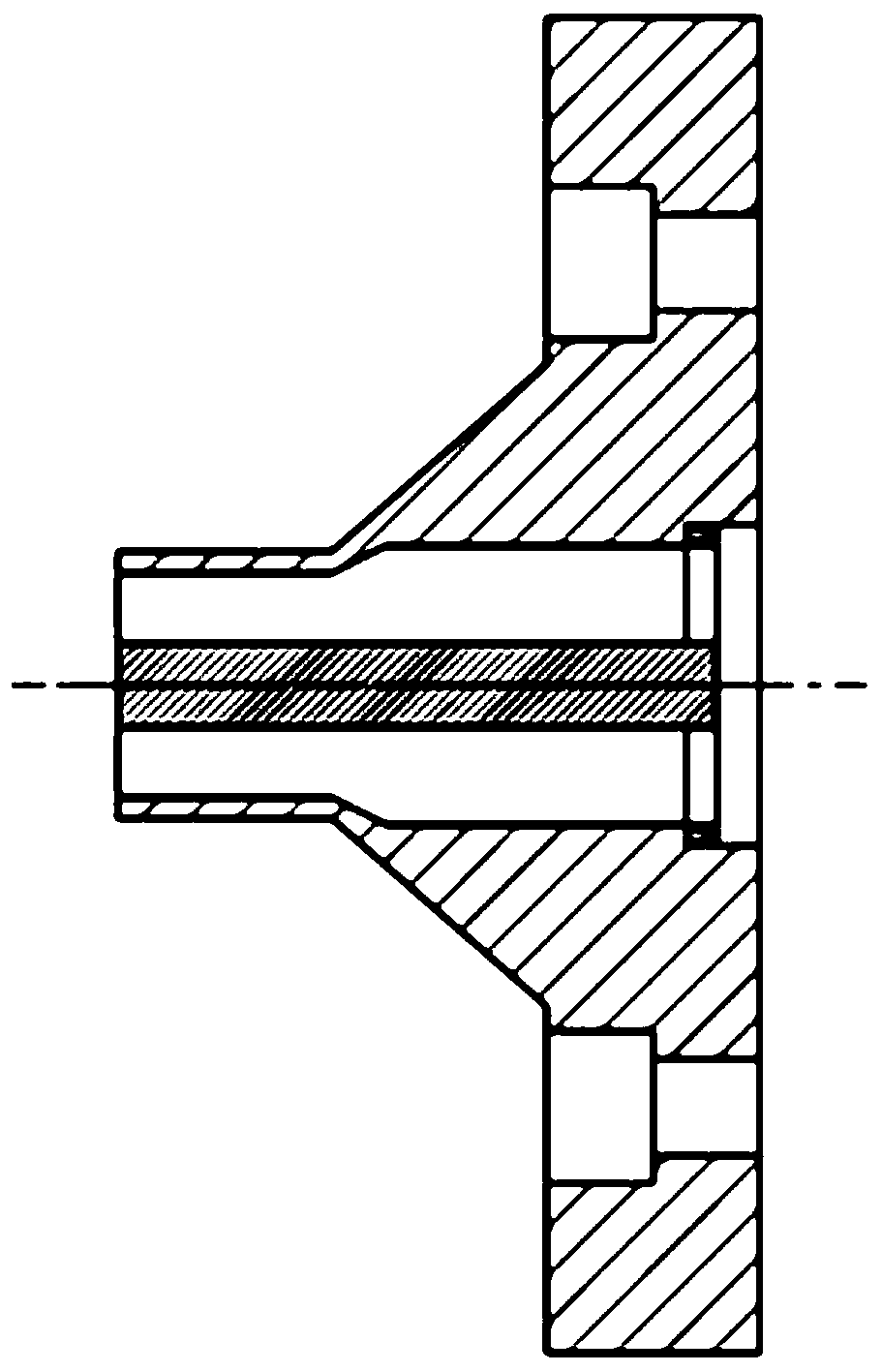

[0085] (Ⅲ) the mixed slurry obtained in step (Ⅱ) is subjected to the following conditions at 30°C image 3 The die head shown is extruded, then conveyed by a conveyor, cut by an automatic cutting machine, and dried at 120°C to obtain a hollow carbon rod.

[0086] The front view and top view of the hollow carbon rod obtained in this embodiment are as follows Figure 6 and Figure 7 As shown, it can be seen from the figure tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com