Interlocking type all-solid-state lithium ion battery membrane blank and forming method and forming device thereof

A technology of lithium ion battery and forming method, which is applied in the direction of secondary battery, electrolyte storage battery manufacturing, non-aqueous electrolyte storage battery, etc., can solve the problem of unsatisfactory interface contact area and interface contact effect between polymer solid electrolyte membrane and positive and negative pole pieces, Affect the overall performance of the flexible battery preparation battery, long battery production cycle, etc., to achieve the effect of shortening the production cycle, large interface contact area, and overall performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

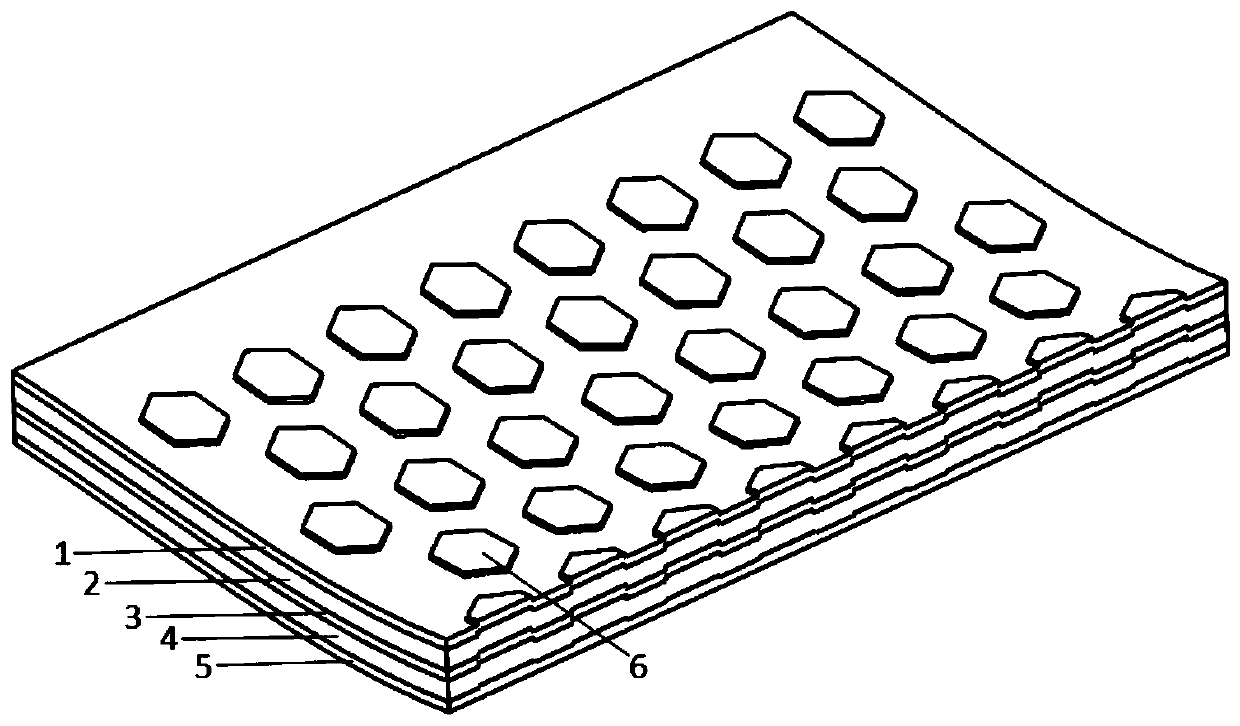

[0045] In this embodiment, an interlocking all-solid-state lithium-ion battery membrane embryo, such as figure 1 As shown, it is an integrated multi-layer structure with an integral interlocking structure 6, including a positive pole piece, a polymer solid electrolyte membrane 3 and a negative pole piece, and the positive pole piece, the polymer solid electrolyte membrane and the negative pole piece are connected in sequence And the three form an integral interlocking structure; the integral interlocking structure is a groove-like or protruding interlocking structure in which multi-layer structures are superimposed, and in this embodiment it is a boss-like structure.

[0046] Wherein, the positive electrode sheet includes a positive electrode current collector 1 and a positive electrode active layer 2, and the positive electrode active layer is arranged between the polymer solid electrolyte membrane and the positive electrode current collector; the negative electrode sheet incl...

Embodiment 2

[0050] This embodiment is a method and device for forming an interlocking all-solid-state lithium-ion battery membrane embryo, which is suitable for jointly processing and forming a polymer solid-state electrolyte membrane, a positive pole piece, and a negative pole piece.

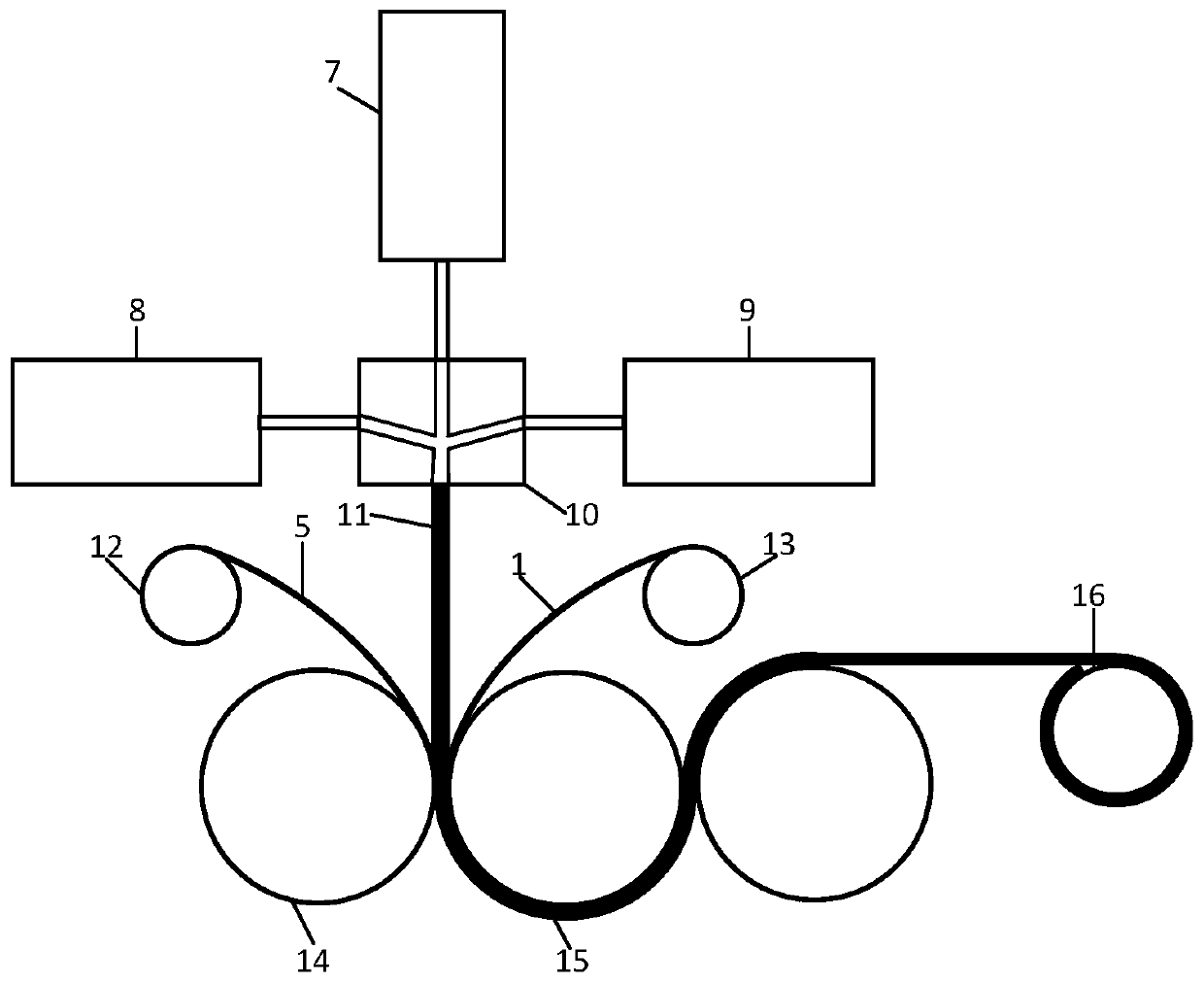

[0051] Such as figure 2 As shown, the forming device of the interlocking all-solid-state lithium-ion battery membrane embryo includes a first extruder 7, a second extruder 8, a third extruder 9, a multi-layer co-extrusion die head 10, and a negative electrode current collector sleeve. Barrel 12, positive electrode current collector sleeve 13 and embossing machine, the head of the first extruder, the head of the second extruder and the head of the third extruder are jointly connected to the multi-layer co-extrusion die head, and the positive electrode The current collector sleeve and the negative electrode current collector sleeve are respectively arranged on the outside of the multi-layer co-extrusion die...

Embodiment 3

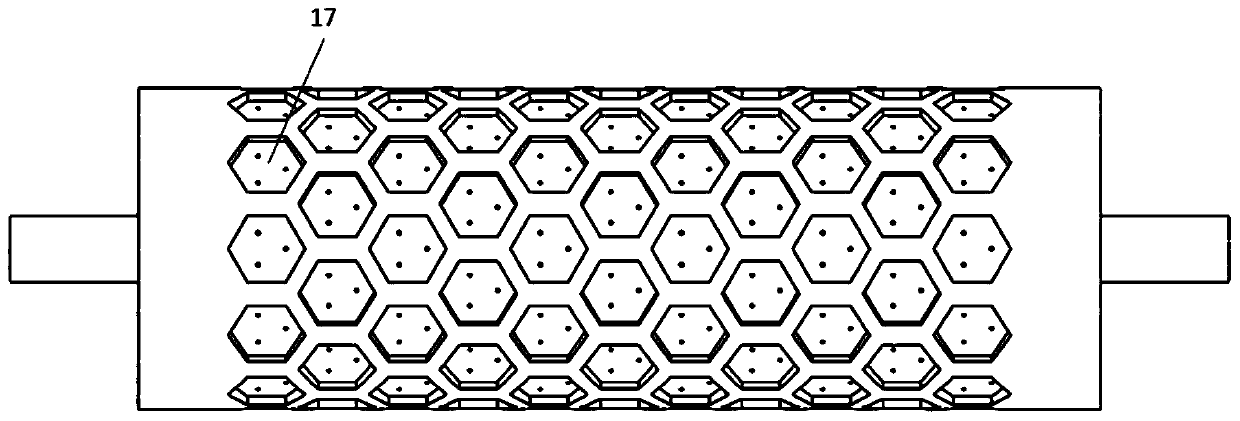

[0060] In this embodiment, a method and device for forming an interlocking all-solid-state lithium-ion battery membrane blank, compared with Embodiment 2, the difference is that: Figure 4 As shown, there is also a vacuum drying oven 18 between the embossing machine and the collection roller. After the interlocking all-solid-state lithium-ion battery membrane embryo is formed, it has a three-dimensional interlocking structure, and then it is further dried in a vacuum drying oven. collect. The molding device is more suitable for use when the positive active layer and the negative active layer are formed by solution extrusion. Among them, each extruder, multi-layer co-extrusion die head, other components of the embossing machine except the vacuum forming roller, vacuum drying oven, etc. can use traditional corresponding devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com