Hybrid polymer electrolyte as well as preparation method and application thereof

A polymer and electrolyte technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve problems such as poor mechanical properties, avoid combustion fragmentation, solve poor mechanical properties, and solve low conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] Correspondingly, taking a lithium-ion battery as an example, the method for preparing a cross-linked hybrid polymer electrolyte includes the following steps:

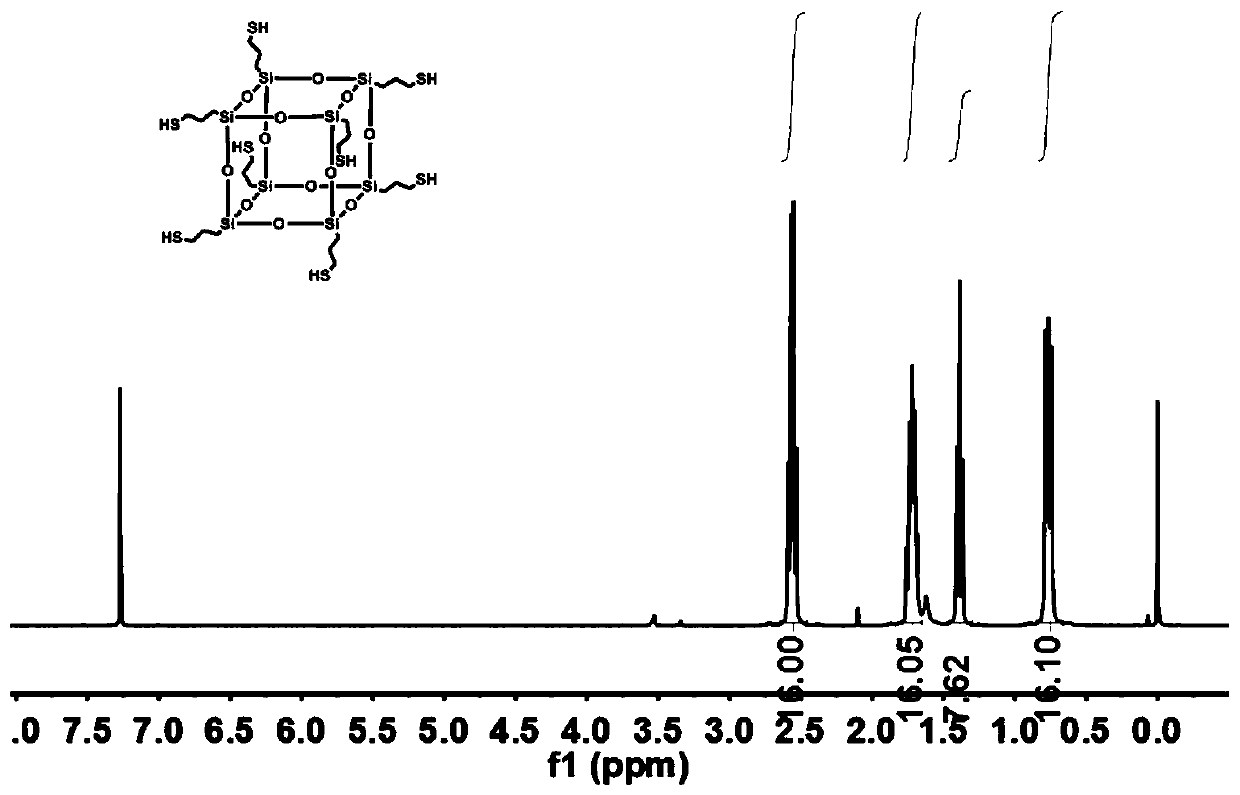

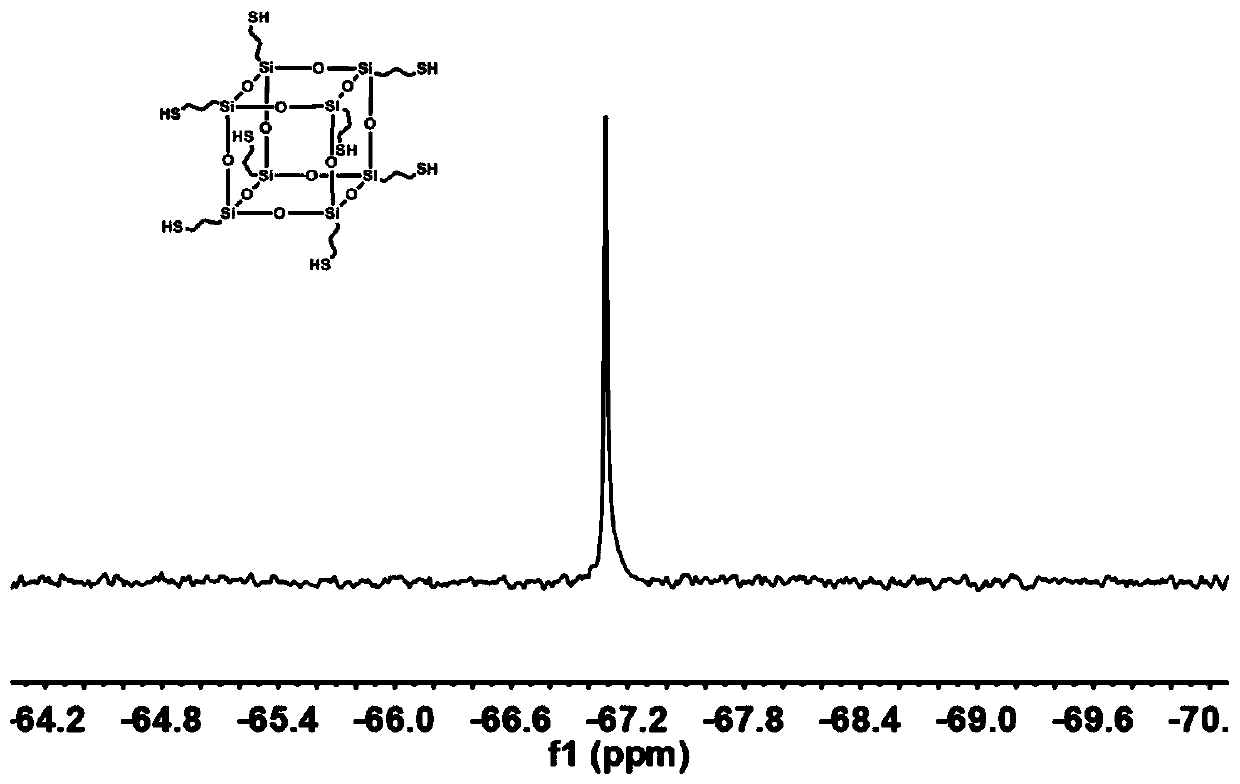

[0074] 1, the synthesis of octamercapto polysilsesquioxane specifically comprises:

[0075] S1: Dissolving γ-mercaptopropyltrimethoxysilane in an organic solvent, adding acid, and stirring to reflux for reaction, standing still to obtain a reaction solution;

[0076] S2: Mix the reaction solution obtained in step S1 with a precipitating agent to form a precipitate, filter and dry to obtain octamercapto polysilsesquioxane;

[0077] II. Synthesis of crosslinking agent polyethylene glycol dimethacrylate:

[0078] S3: Dissolving polyethylene glycol in an organic solvent to obtain a polyethylene glycol solution, adding alkali and methacryloyl chloride to the polyethylene glycol solution, and reacting to obtain a colorless transparent solution;

[0079] S4: Mix the colorless transparent solution obtained in step S3 w...

Embodiment 1

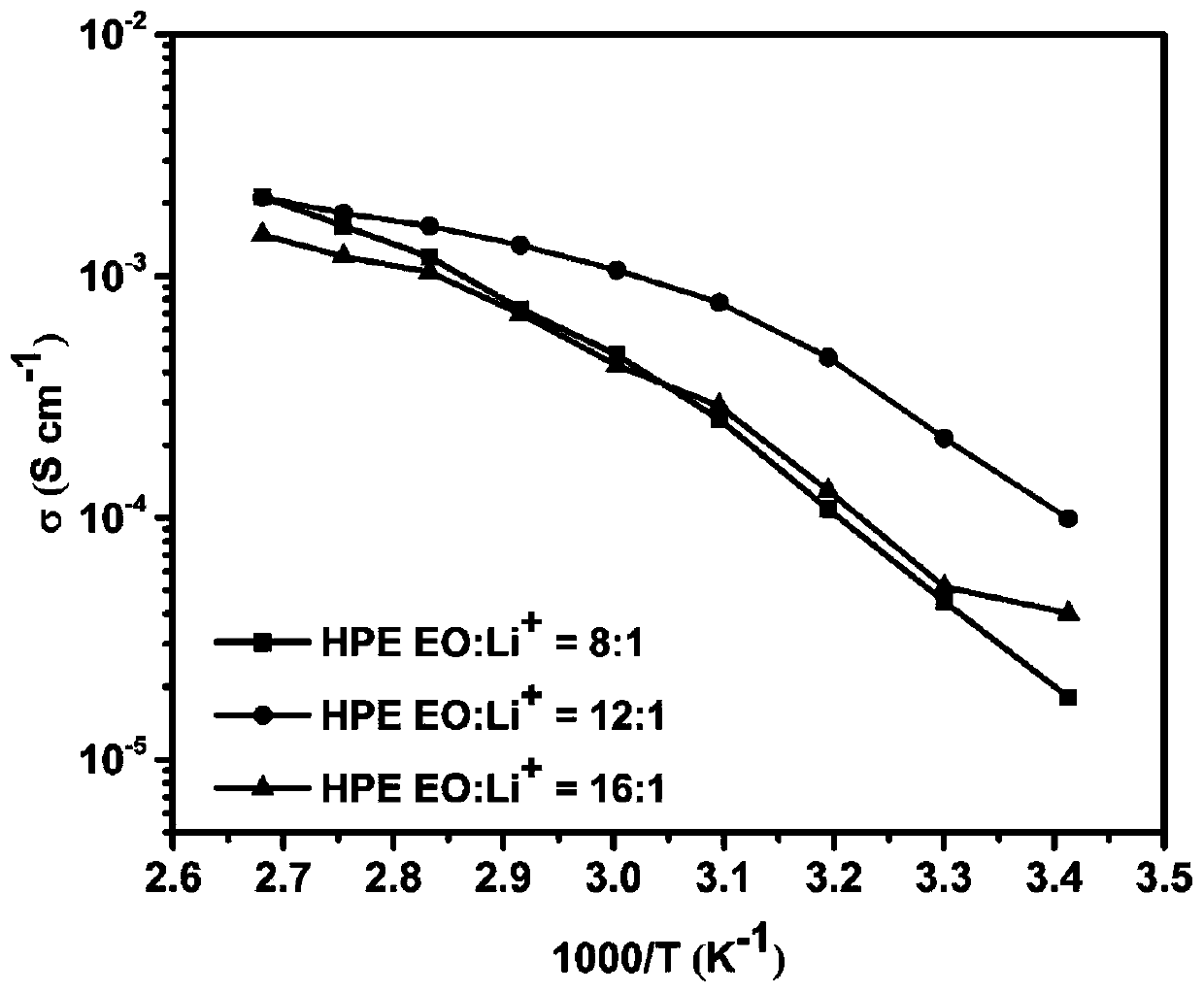

[0106] A hybrid polymer electrolyte, including lithium salt, octamercapto polysilsesquioxane as the core, polyethylene glycol dimethacrylate PEGDMA 200 It is a cross-linked polymer composed of cross-linked arms.

[0107] The preparation method of the hybrid polymer electrolyte is as follows: 15.0ml of γ-mercaptopropyltrimethoxysilane and 30ml of concentrated hydrochloric acid were dissolved in 300mL of methanol solution. Under argon protection, with mechanical stirring, the reaction was refluxed at 50° C. for 5 days. After the reaction is over, let it stand still, and pour out the remaining reaction solution. The white viscous liquid was dissolved in tetrahydrofuran, precipitated with methanol, and dried in a vacuum oven at 50°C for 48 hours to obtain white crystals. After polyethylene glycol 200 is heated and melted, potassium carbonate, tetrahydrofuran and methacryloyl chloride are added to the molten polyethylene glycol, reacted at 0°C, and precipitated with ether to obta...

Embodiment 2

[0111] Octamercapto polysilsesquioxane-polyethylene glycol dimethacrylate PEGDMA 4000 hybrid polymer electrolytes.

[0112] The preparation method of the hybrid polymer electrolyte is as follows: 15.0ml of γ-mercaptopropyltrimethoxysilane and 30ml of concentrated hydrochloric acid are dissolved in 300ml of acetonitrile solution. Under argon protection, with mechanical stirring, the reaction was refluxed at 120° C. for 1 day. After the reaction is over, let it stand still, and pour out the remaining reaction solution. Dissolve the white viscous liquid with dichloromethane, precipitate methanol, and dry in a vacuum oven at 50°C for 48 hours to obtain white crystals. After heating and melting polyethylene glycol 4000, add potassium carbonate, tetrahydrofuran and methacryloyl chloride to the melted polyethylene glycol, react at 50°C, and precipitate from n-heptane to obtain polyethylene glycol dimethacrylate PEGDMA 4000 .

[0113] Put into 254mg octamercapto polysilsesquioxan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com