Production method of instant fermented steamed brown rice

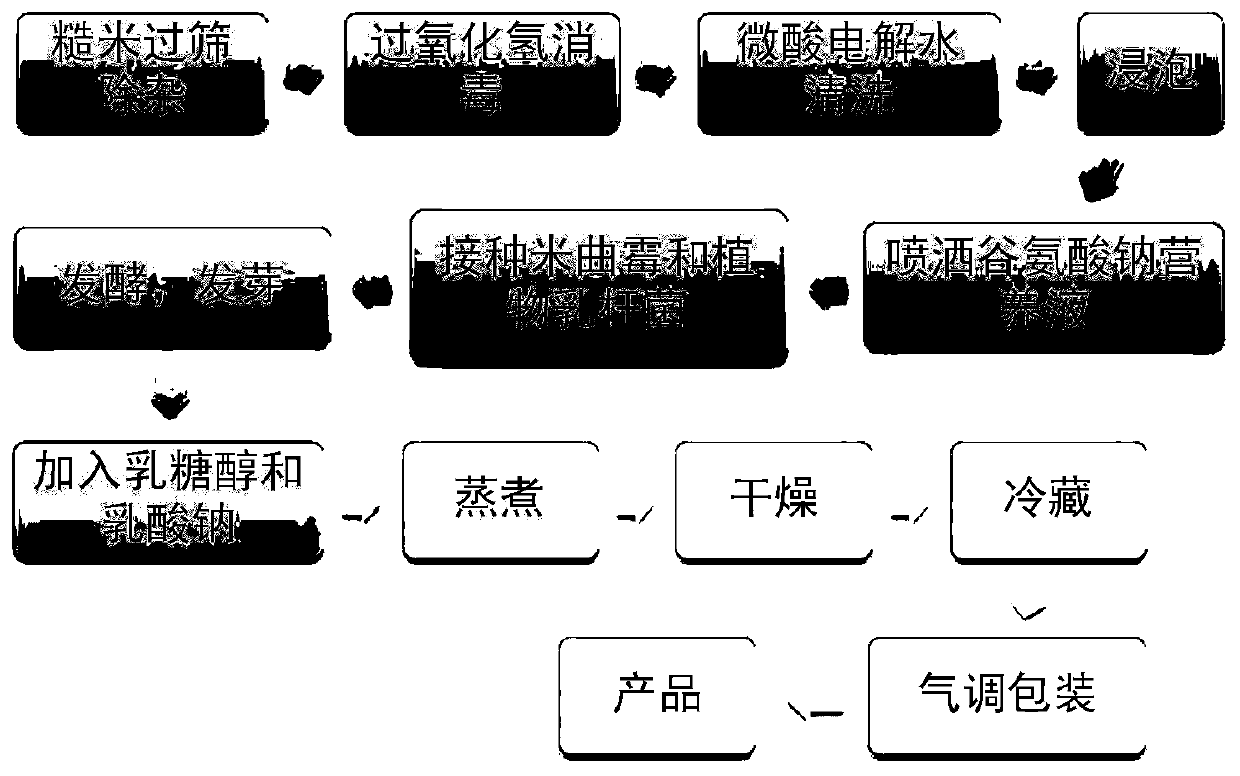

A production method and a technology for germinated brown rice, which are applied in the field of deep processing of grains, can solve the problems of difficulty in determining compound strains, destroy the texture characteristics of germinated brown rice, etc., and achieve the effects of shortening cooking time, eliminating bad flavor and improving nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

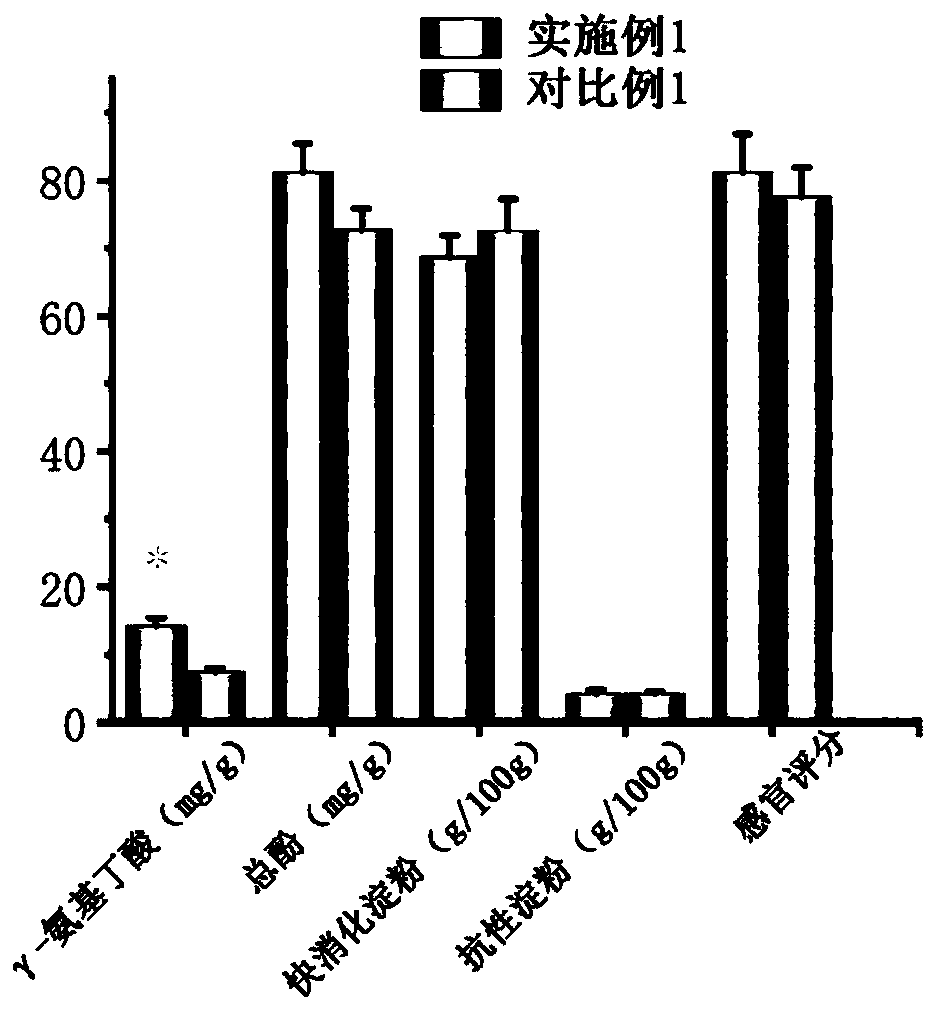

Embodiment 1

[0050] A kind of production method of instant germinated brown rice comprises the following steps:

[0051] S1. Select fresh, non-rotten brown rice, sieve and remove impurities, soak and disinfect with 1% hydrogen peroxide solution for 5 minutes, and then wash twice with slightly acidic electrolyzed water with an effective chlorine concentration of 25mg / L and drain the brown rice grains surface moisture.

[0052] S2. Soak brown rice in slightly acidic electrolyzed water at a temperature of 30° C. for 8 hours, and then wash with slightly acidic electrolyzed water with an available chlorine concentration of 25 mg / L.

[0053] S3, spread the brown rice on gauze and spray 1.5g / L sodium glutamate nutrient solution, the ambient temperature for germination is 32°C, and the relative humidity is 90%. Inoculate 0.1% Aspergillus oryzae and 0.1% Lactobacillus plantarum. Sodium glutamate nutrient solution was sprayed every 6 hours, and the germination time was 24 hours.

[0054] S4. Mix ...

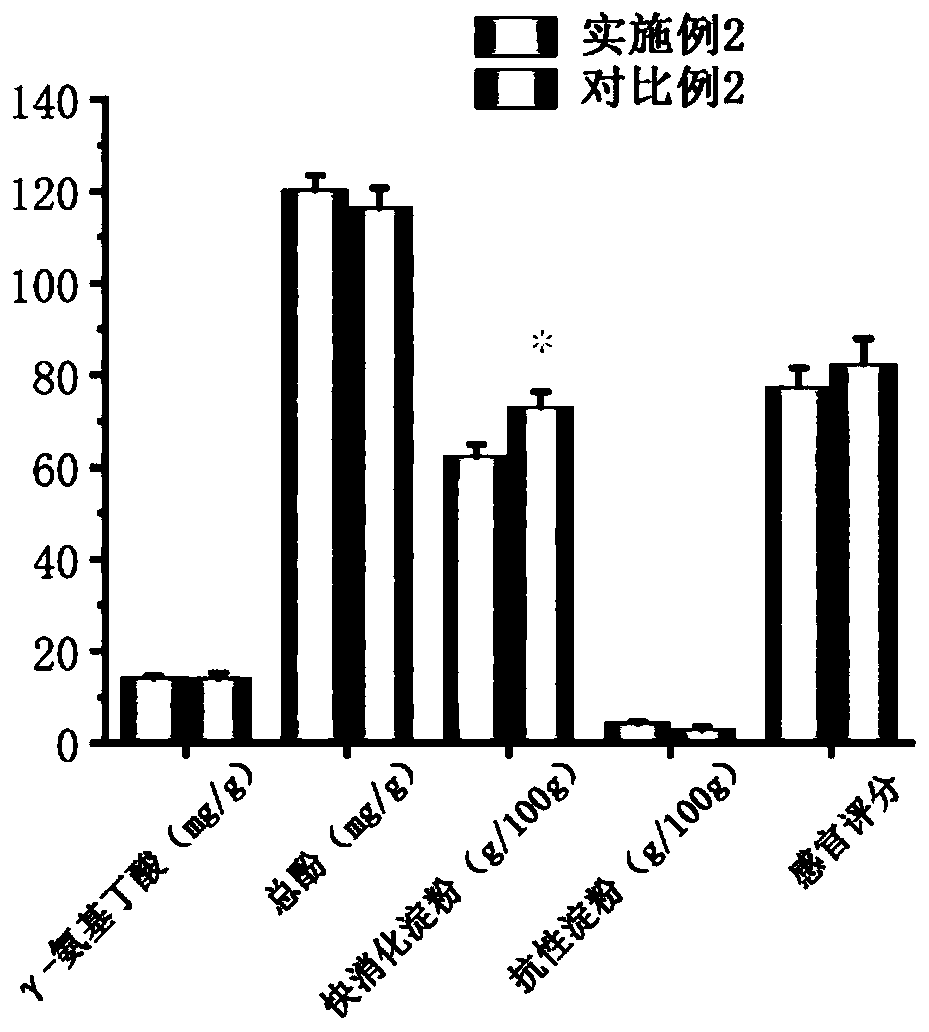

Embodiment 2

[0060] A kind of production method of instant germinated brown rice comprises the following steps:

[0061] S1. Select fresh, non-rotten brown rice, sieve and remove impurities, soak and disinfect with 1.5% hydrogen peroxide solution for 10 minutes, then wash twice with slightly acidic electrolyzed water with an effective chlorine concentration of 30 mg / L and drain the surface of the brown rice grains moisture.

[0062] S2. Soak the brown rice in slightly acidic electrolyzed water with a temperature of 35° C. for 10 hours, and then wash it with slightly acidic electrolyzed water with an available chlorine concentration of 30 mg / L.

[0063] S3, spread the brown rice on gauze and spray 2g / L sodium glutamate nutrient solution, the germination environment temperature is 35°C, and the relative humidity is 95%. Inoculate with 0.2% Aspergillus oryzae and 0.2% Lactobacillus plantarum. Sodium glutamate nutrient solution was sprayed every 6 hours, and the germination time was 22 hours...

Embodiment 3

[0070] A kind of production method of instant germinated brown rice comprises the following steps:

[0071] S1. Select fresh, non-rotten brown rice, sieve and remove impurities, soak and disinfect with 2% hydrogen peroxide solution for 15 minutes, then wash twice with slightly acidic electrolyzed water with an effective chlorine concentration of 25mg / L and drain the surface of the brown rice grains moisture.

[0072] S2. Soak the brown rice in slightly acidic electrolyzed water with a temperature of 32° C. for 13 hours, and then wash it with slightly acidic electrolyzed water with an available chlorine concentration of 25 mg / L.

[0073] S3, spread the brown rice on gauze and spray 1.8g / L sodium glutamate nutrient solution, the germination environment temperature is 33°C, and the relative humidity is 85%. Inoculate 0.15% Aspergillus oryzae and 0.15% Lactobacillus plantarum. Sodium glutamate nutrient solution was sprayed every 6 hours, and the germination time was 26 hours.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com