Breathable antibacterial insole material for sports and leisure shoes

A technology for casual shoes and insoles, applied in insoles, footwear, applications, etc., can solve the problems of inability to promote dynamic balance maintenance, inability to integrate insole structures, and limited moisture absorption and breathability, so as to promote sustainable development of resources and promote rapid development. Effects of developing and resolving functional deficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

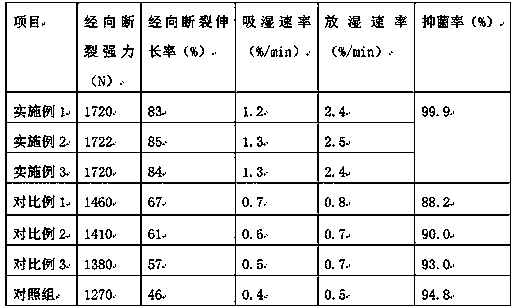

Examples

Embodiment 1

[0019] A breathable and antibacterial sports shoe insole material, which is made of stitched non-woven fabric coated with modified styrene-butadiene latex. The preparation process of the modified styrene-butadiene latex includes the following steps:

[0020] (1) Weigh 20 g of aluminum sulfate, add 2.7 g of calcium chloride and mix it evenly, place it in the reactor, add 120 ml of deionized water, continue to stir and mix for 30 minutes after the exothermic reaction begins, and then add 25 ml of water glass The solution, continue to stir for 20 minutes, mix well with 14 ml of barium chloride aqueous solution, let stand and age for 8 hours, naturally cool to 20°C, use a high-speed centrifuge to separate the solid precipitate, use absolute ethanol to wash to neutral, set Dry in a drying oven at 90°C for 7 hours to obtain a silicate / barium salt composite material;

[0021] (2) Weigh 500 grams of fly ash, grind it through a 0.1 mm sieve, add 3.0 times the volume of water, soak in water ...

Embodiment 2

[0030] A breathable and antibacterial sports shoe insole material, which is made of stitched non-woven fabric coated with modified styrene-butadiene latex. The preparation process of the modified styrene-butadiene latex includes the following steps:

[0031] (1) Weigh 21 g of aluminum sulfate, add 2.75 g of calcium chloride and mix it evenly, place it in the reactor, add 125 ml of deionized water, continue to stir and mix for 35 minutes after the exothermic reaction begins, and then add 25-30 ml of Water glass solution, continue to stir for 25 minutes, mix well with 16 ml of barium chloride aqueous solution, let stand and age for 9 hours, naturally cool to 22°C, use a high-speed centrifuge to separate the solid precipitate, use absolute ethanol to wash until neutral , Placed in a 95°C drying oven for 7.5 hours to obtain a silicate / barium salt composite material;

[0032] (2) Weigh 505 grams of fly ash, grind it through a 0.15 mm sieve, add 3.2 times the volume of water, soak in wat...

Embodiment 3

[0041] A breathable and antibacterial sports shoe insole material, which is made of stitched non-woven fabric coated with modified styrene-butadiene latex. The preparation process of the modified styrene-butadiene latex includes the following steps:

[0042] (1) Weigh 22 g of aluminum sulfate, add 2.8 g of calcium chloride and mix it evenly, place it in the reactor, add 130 ml of deionized water, continue to stir and mix for 40 minutes after the exothermic reaction begins, and then add 30 ml of water glass The solution, continue to stir for 30 minutes, mix well with 18 ml of barium chloride aqueous solution, let stand for 10 hours, naturally cool to 25°C, use a high-speed centrifuge to separate the solid precipitate, use absolute ethanol to wash to neutral, set Dry in a drying oven at 100°C for 8 hours to obtain a silicate / barium salt composite material;

[0043] (2) Weigh 510 grams of fly ash, grind it through a 0.2 mm sieve, add 3.5 times the volume of water, soak in water for 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com