Sodium alginate-based loaded nano-pyrophanite/lignite-based active coke hydrogel and preparation method thereof

A technology of sodium alginate and manganese ore is applied in water/sewage treatment, chemical instruments and methods, adsorbed water/sewage treatment, etc., to achieve the effects of convenient operation, simple preparation process, and avoidance of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

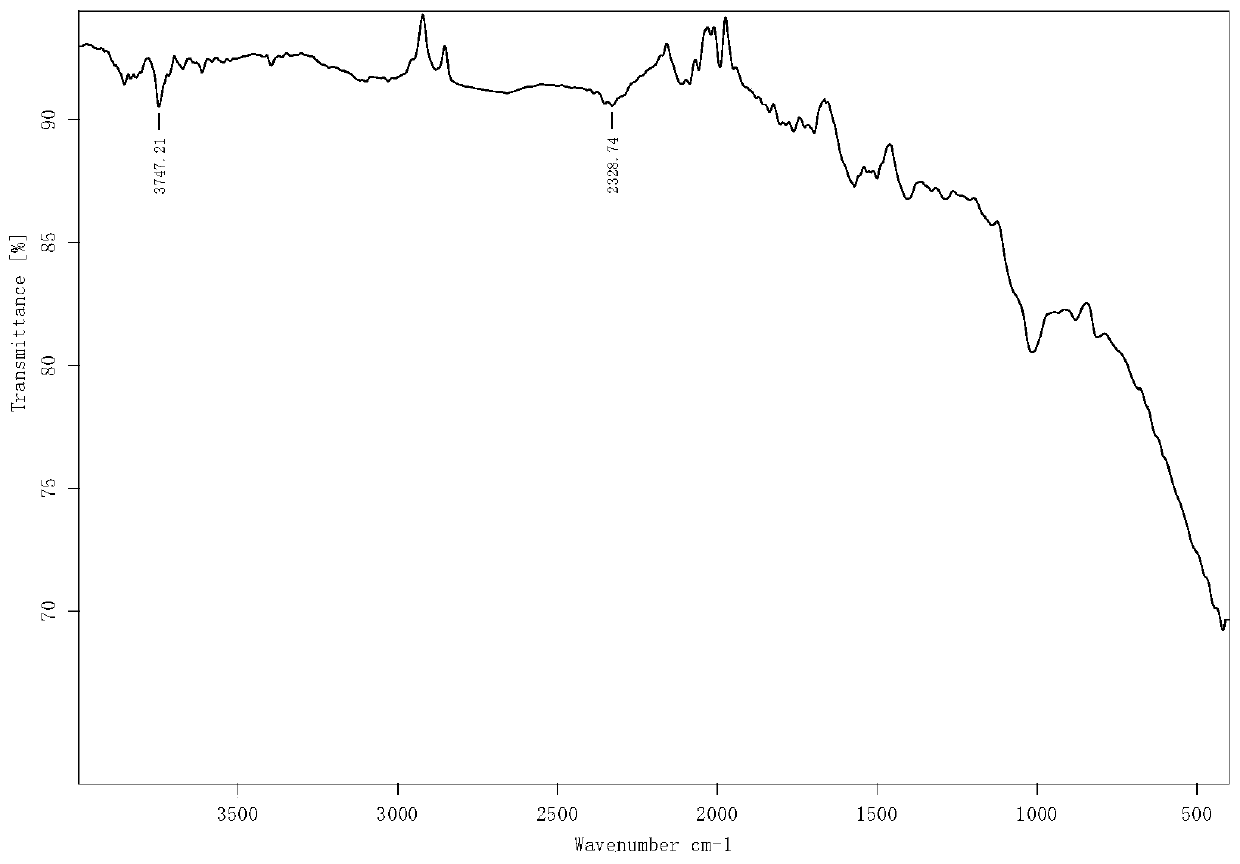

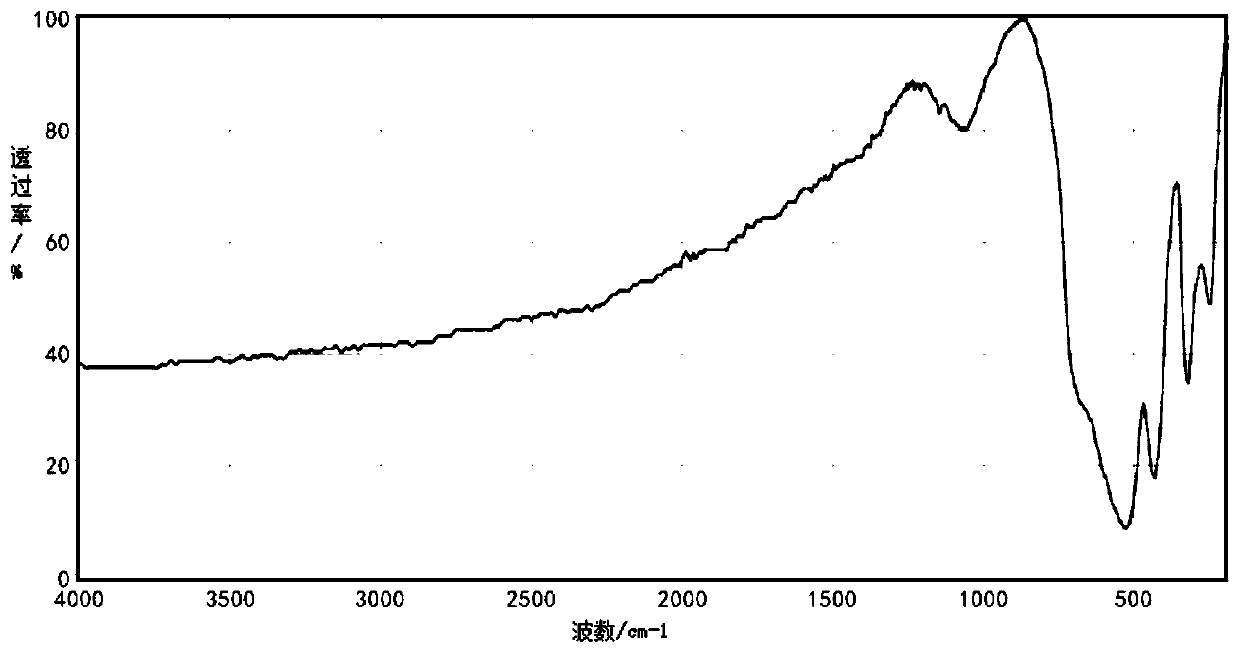

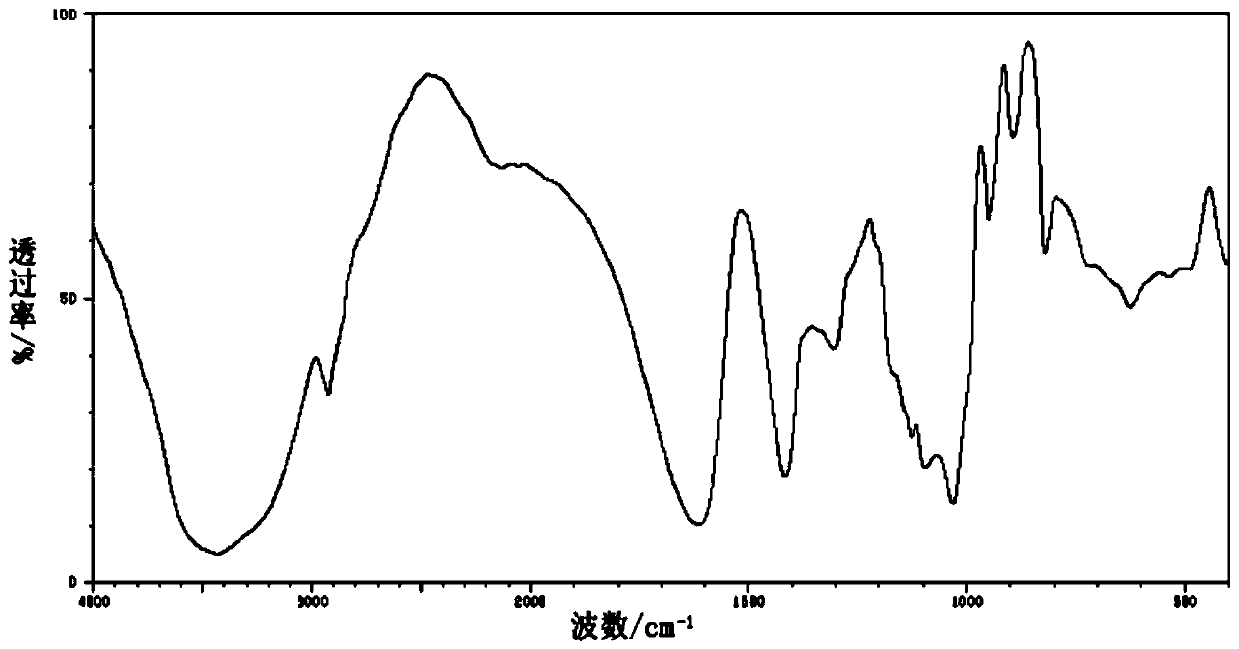

Image

Examples

Embodiment 1

[0035] This embodiment provides a method for preparing a sodium alginate-based loaded nano-red ilmenanite / lignite-based activated coke hydrogel, comprising the following steps:

[0036] S1. Preparation of sodium alginate solution: take an appropriate amount of sodium alginate powder, and then prepare a sodium alginate solution with a concentration of 2wt% with ultrapure water. During the preparation process, an egg beater can be used to continuously stir the solution for 10 minutes to obtain a uniform Sodium alginate solution, spare;

[0037] S2. Prepare mixed solution: add ilmenanite / brignite-based active coke powder to the sodium alginate solution obtained in step S1 to obtain a mixed solution, the mass ratio of sodium alginate solution to ilmenanese / lignite-based active coke powder is 4: 1. Then add ultra-pure water and stir evenly to obtain it; wherein, the concentration of ilmenanite / lignite-based active coke in the above mixed solution is 2wt%;

[0038] S3. Preparation ...

Embodiment 2

[0048] This embodiment provides a method for preparing a sodium alginate-based loaded nano-red ilmenanite / lignite-based activated coke hydrogel, comprising the following steps:

[0049] S1. Preparation of sodium alginate solution: take an appropriate amount of sodium alginate powder, and then prepare a sodium alginate solution with a concentration of 5wt% with ultrapure water. During the preparation process, an egg beater can be used to continuously stir the solution for 20 minutes to obtain a uniform Sodium alginate solution, spare;

[0050] S2. Prepare mixed solution: add ilmenanese / brignite-based active coke powder to the sodium alginate solution obtained in step S1 to obtain a mixed solution, the mass ratio of sodium alginate solution to ilmenanese / lignite-based active coke powder is 3: 1. Then add ultra-pure water and stir evenly to obtain it; wherein, the concentration of ilmenanite / lignite-based active coke in the above mixed solution is 1wt%;

[0051] S3. Preparation ...

Embodiment 3

[0057] This embodiment provides a method for preparing a sodium alginate-based loaded nano-red ilmenanite / lignite-based activated coke hydrogel, comprising the following steps:

[0058] S1. Preparation of sodium alginate solution: Take an appropriate amount of sodium alginate powder, and then use ultrapure water to prepare a sodium alginate solution with a concentration of 2.5wt%. Sodium alginate solution, spare;

[0059] S2. Prepare mixed solution: add ilmenanese / lignite-based active coke powder to the sodium alginate solution obtained in step S1 to obtain a mixed solution, the mass ratio of sodium alginate solution to ilmenanese / lignite-based active coke powder is 2: 1. Then add ultra-pure water and stir evenly to obtain it; wherein, the concentration of ilmenanite / lignite-based active coke in the above mixed solution is 1.25wt%;

[0060] S3. Preparation of hydrogel

[0061] S31. Preparation of calcium chloride solution: take an appropriate amount of calcium chloride, prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com