Spiral roll type electric desalted water treatment system and operation method

A treatment system, spiral coil technology, applied in multi-stage water treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of large floor space, unfavorable installation, unfavorable maintenance, etc., to save The effect of system piping and floor space, reducing scaling, improving salt rejection and working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

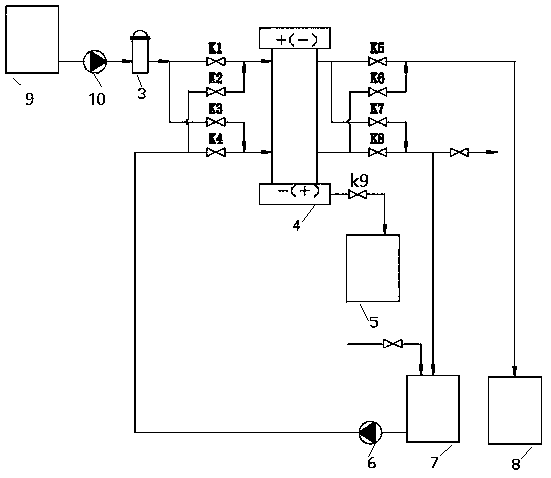

Embodiment 1

[0109] The total hardness of raw water is about 360mg / L, the total alkalinity is 100mg / L, and the conductivity is 2500us / cm. When the spiral-wound electric desalter is running, valves K1 and K4 at the water inlet are opened; K2 and K3 are closed; valves K5 and K8 at the water outlet are opened; K6 and K7 are closed. Adjust the flow rate of influent and concentrated water to 0.5m 3 / h, polar water flow 25L / h. Produced water and polar water are discharged directly, and concentrated water is circulated. After evacuating the air in the module, start the DC power supply and gradually increase the working voltage to 33V. At this time, the working current is 10A. Gradually increase the conductivity of the concentrated water inlet to 7000us / cm. After the system working condition is stable, switch electrode operation every 15 minutes. Specific steps are as follows:

[0110] Valve K5 is closed, K7 is opened, and the fresh water outlet is switched to the concentrated water tank.

...

Embodiment 2

[0118] The total hardness of raw water is about 360mg / L, the total alkalinity is 100mg / L, and the conductivity is 2500us / cm. When the spiral-wound electric desalter is running, valves K1 and K4 at the water inlet are opened; K2 and K3 are closed; valves K5 and K8 at the water outlet are opened; K6 and K7 are closed. Adjust the flow rate of influent and concentrated water to 0.5m 3 / h, polar water flow 25L / h. Produced water and polar water are discharged directly, and concentrated water is circulated. After evacuating the air in the module, start the DC power supply and gradually increase the working voltage to 33V. At this time, the working current is 10A. Gradually increase the conductivity of the concentrated water inlet to 7000us / cm. After the system working condition is stable, switch electrode operation every 20 minutes. Specific steps are as follows:

[0119] Valve K5 is closed, K7 is opened, and the fresh water outlet is switched to the concentrated water tank.

...

Embodiment 3

[0127] The total hardness of raw water is about 360mg / L, the total alkalinity is 100mg / L, and the conductivity is 2500us / cm. When the spiral-wound electric desalter is running, valves K1 and K4 at the water inlet are opened; K2 and K3 are closed; valves K5 and K8 at the water outlet are opened; K6 and K7 are closed. Adjust the flow rate of influent and concentrated water to 0.5m 3 / h, polar water flow 25L / h. Produced water and polar water are discharged directly, and concentrated water is circulated. After evacuating the air in the module, start the DC power supply and gradually increase the working voltage to 33V. At this time, the working current is 10A. Gradually increase the conductivity of the concentrated water inlet to 7000us / cm. After the system working condition is stable, switch electrode operation every 30 minutes. Specific steps are as follows:

[0128] Valve K5 is closed, K7 is opened, and the fresh water outlet is switched to the concentrated water tank.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total alkalinity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Total alkalinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap