Method and device for preparing L-selenocystine by using sodium triacetoxyborohydride as reducing agent

A technology of sodium triacetoxyborohydride and selenocystine, which is applied in the field of chemical conversion, can solve the problems of high risk, severe reaction, troublesome gas post-processing, etc., and achieves high utilization rate of raw materials, green process, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

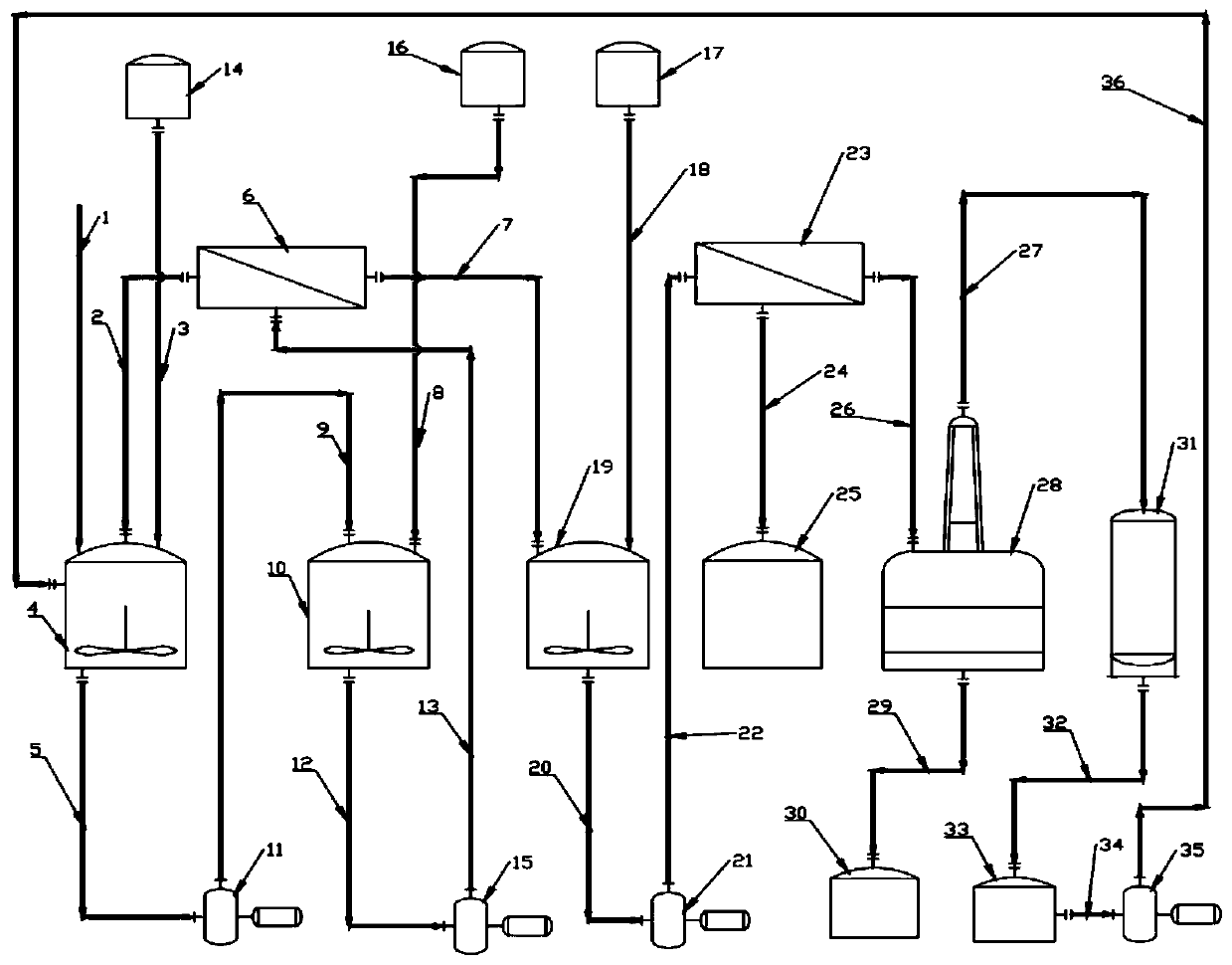

Method used

Image

Examples

Embodiment 1

[0032] Step 1, 3.0 grams of selenium powder, 4.8 grams of potassium hydroxide, and 4.9 grams of sodium triacetoxyborohydride are loaded into the reactor, then 40 mL of distilled water is added, and finally 30 mL of 30 mL of 0.5 g / mL (pH=9.5) of 3 -The aqueous solution of chloro-L-alanine was added to the reactor, and the stirring was continued at room temperature for 28 hours (stirring speed was 600r / min);

[0033] Step 2, transfer the material to the acid mixer after the reaction is completed, adjust the pH of the solution to 2 with dilute sulfuric acid (6.0mol / L), so that a large amount of selenium powder precipitates, filter out the excess selenium powder through the filter, and the filtrate is transferred to the alkali mixer , and add potassium hydroxide to adjust the pH to about 6.5, let it stand for 3 days, then transfer the material to the filter, and the filtrate is evaporated to collect solid waste. The filter residue was selenocystine, weighed 1.63 g after drying, an...

Embodiment 2

[0035] Step 1, 2.0 grams of selenium powder, 2.4 grams of potassium hydroxide, and 2.9 grams of sodium triacetoxyborohydride are loaded into the reactor, then 20 mL of distilled water is added, and then 10 mL of 3 -The aqueous solution of chloro-L-alanine was added to the reactor, and stirred at room temperature for 18 hours (stirring speed was 800r / min);

[0036] Step 2, after completing the reaction, transfer the material to an acid mixer, adjust the pH of the solution to 1 with dilute hydrochloric acid (2.0mol / L), filter out excess selenium powder through a filter, and transfer the filtrate to an alkali mixer, and add potassium hydroxide Adjust the pH to about 7, let it stand for 3 days, then transfer the material to the filter, and the filtrate is evaporated to collect solid waste. The filter residue was selenocystine, weighed 1.15 g after drying, and the yield was 85%.

Embodiment 3

[0038] Step 1, 3.0 grams of selenium powder, 30 mL of an aqueous solution of 2.02 mol / L sodium hydroxide, and 4.2 grams of sodium triacetoxyborohydride are loaded into a reactor, and then 10 mL of a concentration of 1 g / mL (pH=9) is added. The aqueous solution of 3-chloro-L-alanine was stirred at room temperature for 19 hours (stirring speed was 600r / min);

[0039] Step 2, after the reaction is completed, transfer the material to an acid mixer, adjust the pH of the solution to 1 with dilute hydrochloric acid, filter out excess selenium powder through a filter, and transfer the filtrate to an alkali mixer, and add potassium hydroxide to adjust the pH to about 7.0, After standing for 1 day, the material was transferred to a filter, and the filtrate was evaporated to collect solid waste. The filter residue was selenocystine, weighed 1.30 g after drying, and the yield was 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com