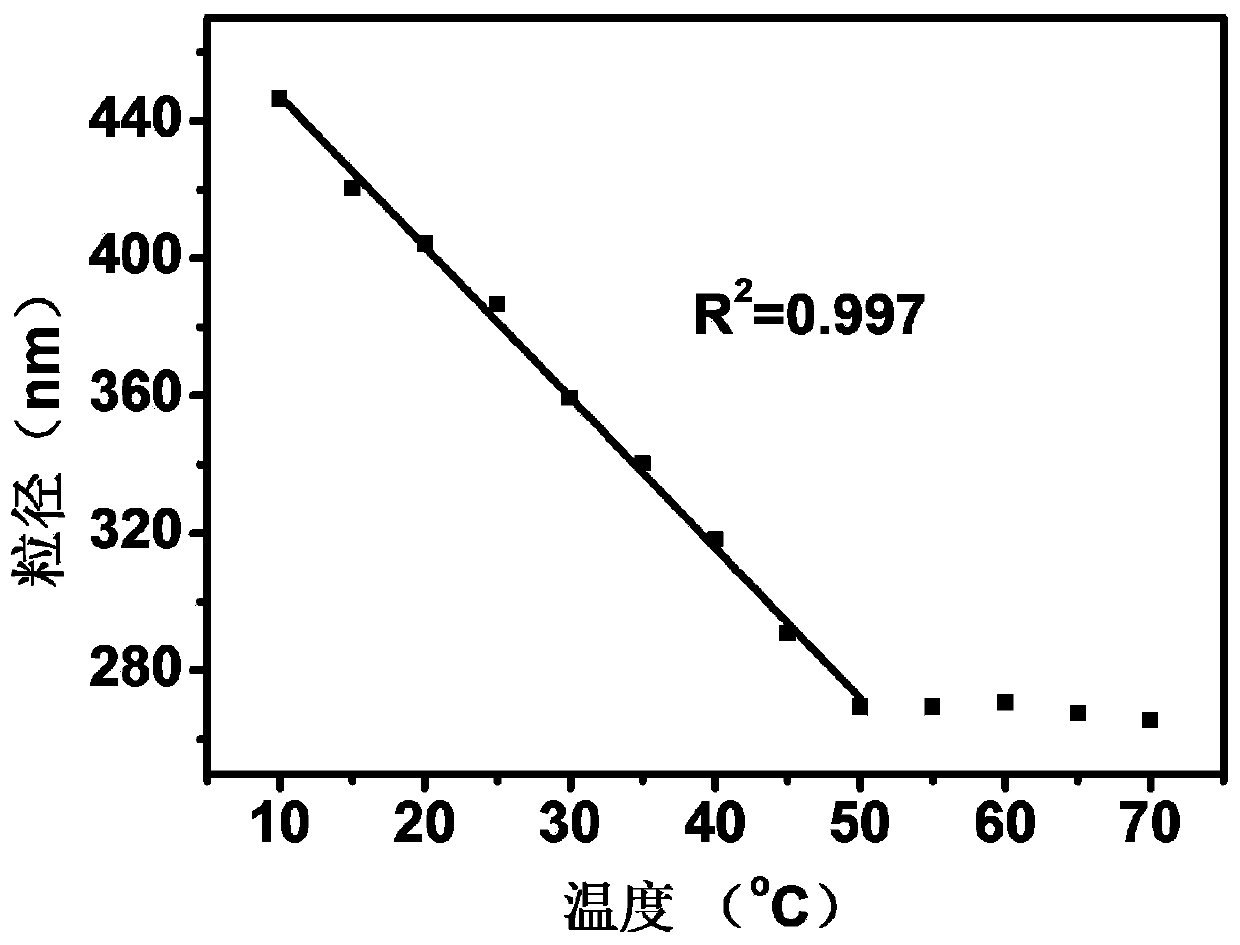

Preparation method of temperature-sensitive microgel uniformly coated with nano iron oxide

A nano-iron oxide, temperature-sensitive technology, applied in the field of preparation of temperature-sensitive microgels, can solve problems such as inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a method for preparing a temperature-sensitive microgel uniformly coated with nanometer iron oxide, comprising the following steps:

[0035] step one

[0036] A determines the amount of added deionized water in the reaction process;

[0037] B According to the amount of deionized water added, three kinds of methoxyethyl acrylate (MEA), oligo(ethylene glycol) methyl ether acrylate (PEGA) and acetoacetate methacrylate (AAEM) were respectively determined. The amount of monomer added;

[0038] C Determine the magnetic iron oxide nanoparticles (γ-Fe 2 o 3 ), polyethylene glycol diacrylate (PEGDA), polyvinylpyrrolidone (PVP) and potassium persulfate (KPS) added (relative to monomer mass).

[0039] In the present invention, three monomers and magnetic iron oxide nanoparticles (γ-Fe2 o 3 ), polyethylene glycol diacrylate (PEGDA), polyvinylpyrrolidone (PVP) and potassium persulfate (KPS), all replaced by chemical formula or English letter abbreviation...

Embodiment 1

[0061] In a 20mL reaction bottle, accurately measure 4.7mL deionized water, and then add accurately weighed 139.3mgMEA, 96.3mg PEGA, 14.3mg AAEM, 7.5mg PEGDA, 50mg PVP, 178.6μL γ-Fe 2 o 3 (1.4 mg / mL). After sealing the reaction bottle, pass nitrogen gas to remove oxygen for 30 minutes, then inject 100 μL of the aqueous solution containing 1.88 mg potassium persulfate previously deoxygenated into the above sealed reaction bottle with a micro syringe, and then quickly transfer it into the oil that has been preheated and the temperature is stable at 70 ° C. In the bath, the stirring speed was controlled to be 800r / min under nitrogen atmosphere, and the reaction was continued for 6h.

Embodiment 2

[0063] Whole reaction process is identical with embodiment 1, only gamma-Fe 2 o 3 The amount added was changed to 893 μL.

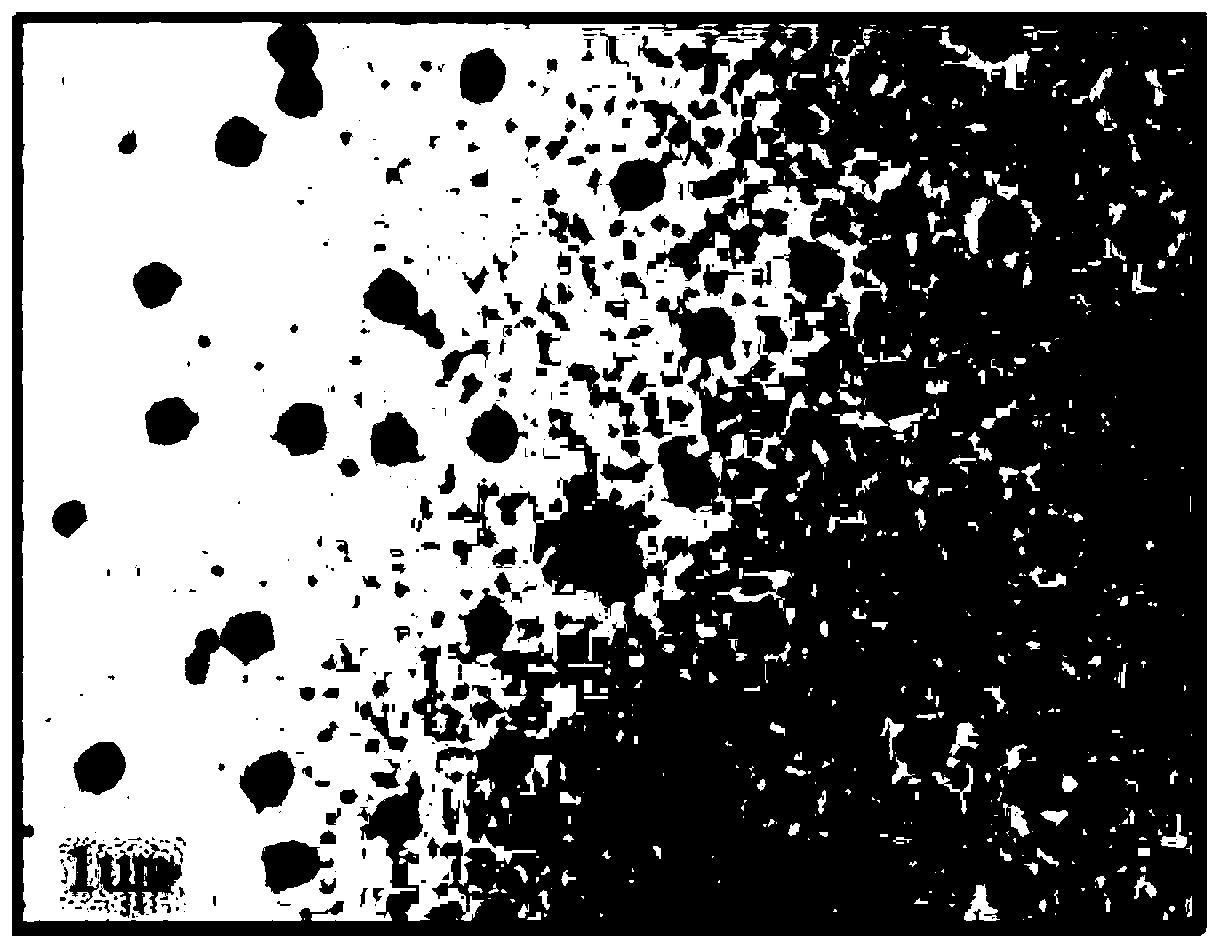

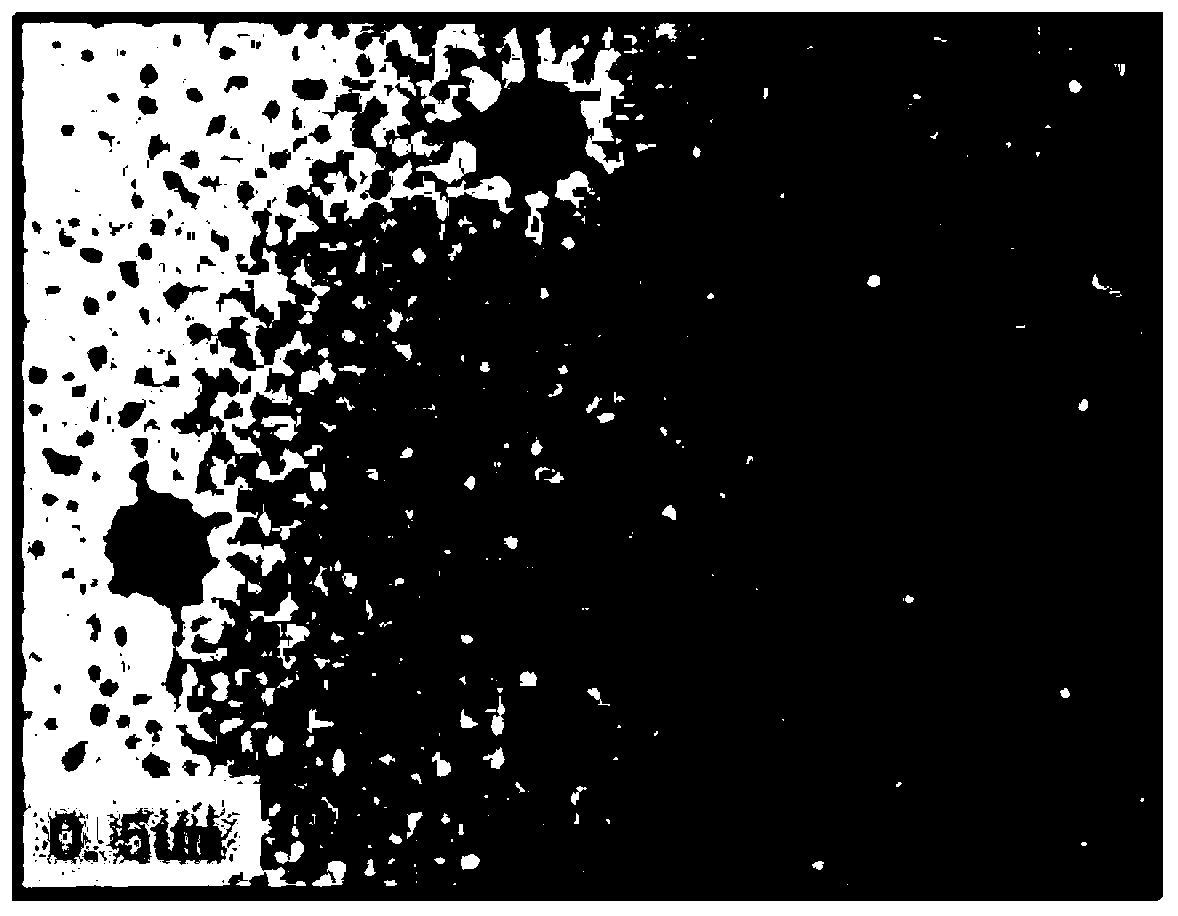

[0064] The TEM spectra of thermosensitive microgels at different magnifications are shown in figure 2 and image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com