A kind of asphalt mixture production equipment and its manufacturing preparation process

A technology of production equipment and preparation technology, which is applied in the field of asphalt mixture production equipment and its manufacturing preparation technology, can solve problems such as easy cracks on the road surface, poor uniformity of asphalt raw materials, and short service life of the road surface, so as to improve various performances, The effect of maintaining the low temperature performance and reducing the temperature sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

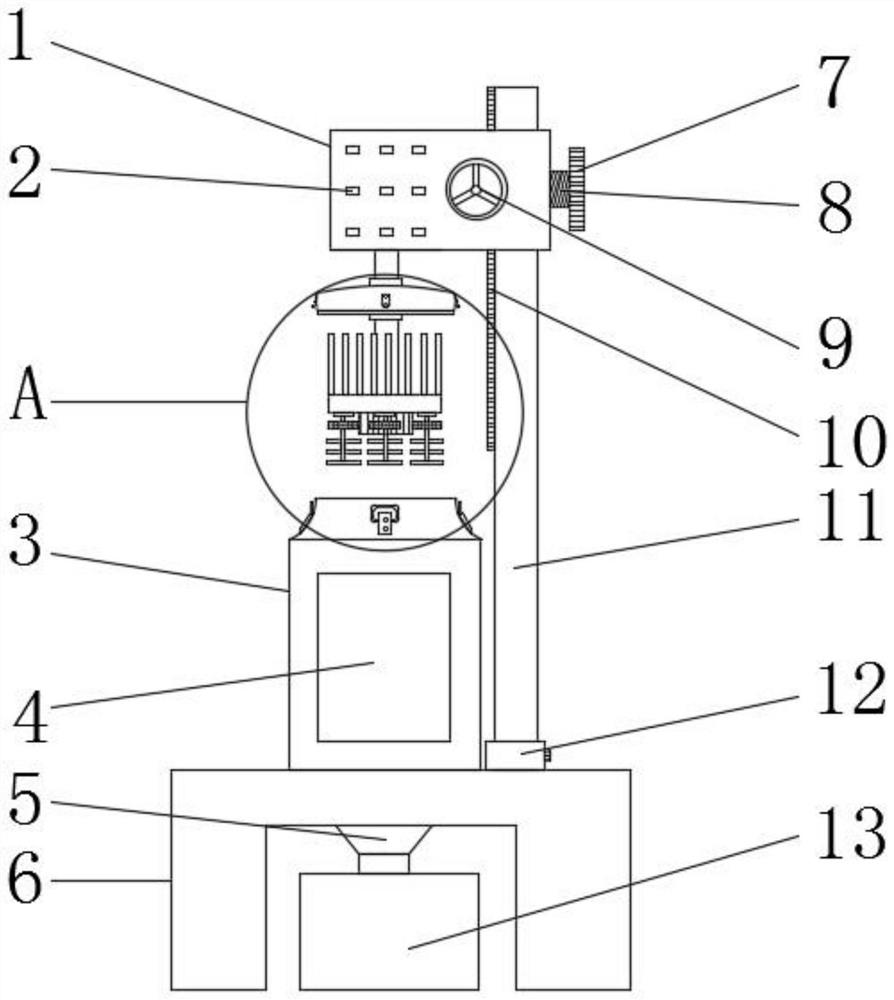

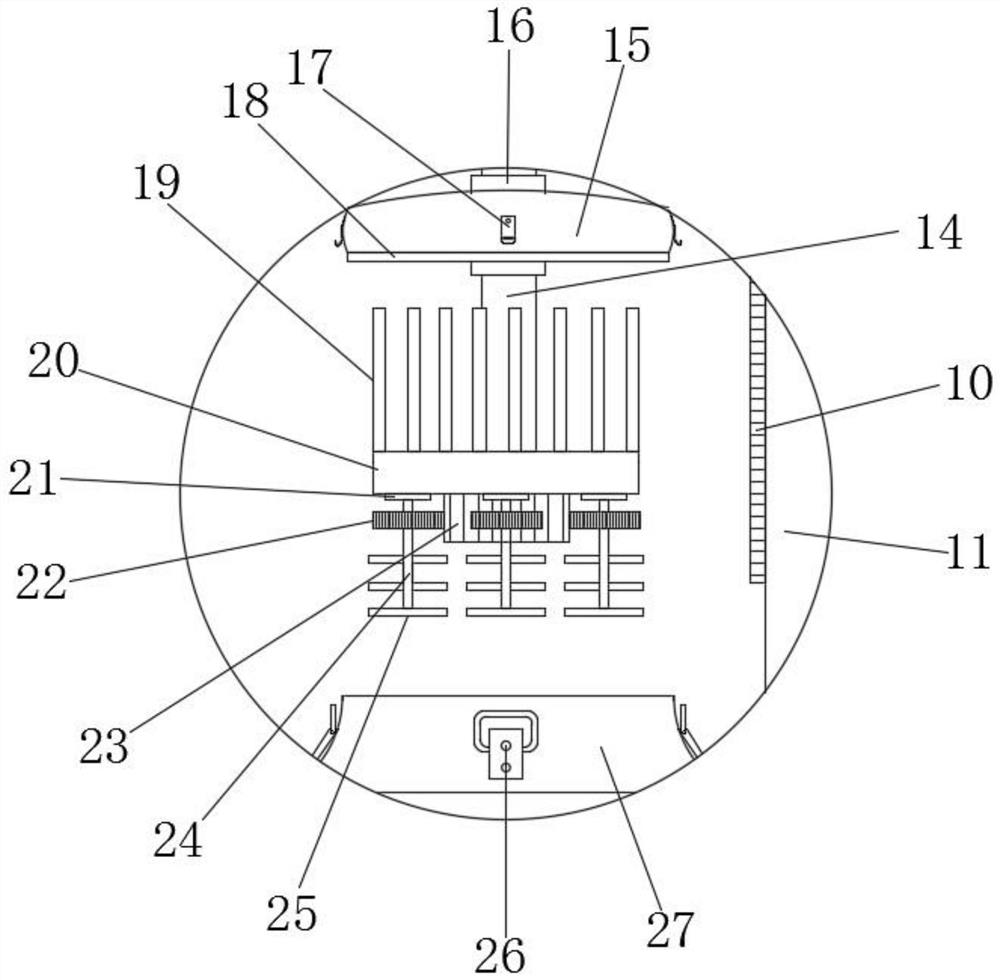

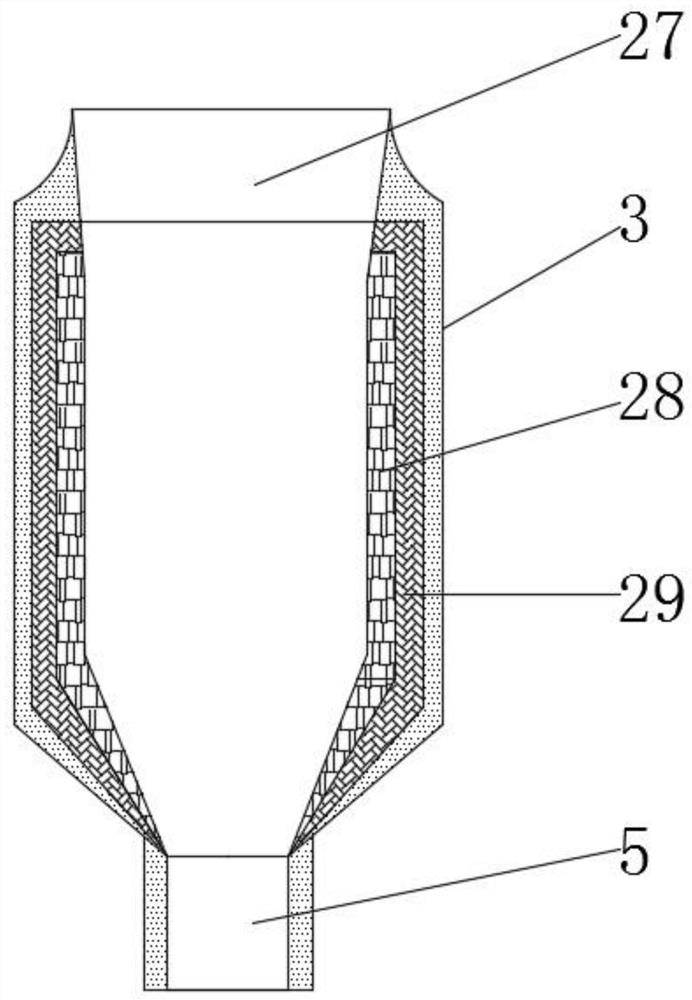

[0041] see Figure 1-6 As shown, the present embodiment is a kind of asphalt mixture production equipment, including a power box 1, a shear box 3, a discharge hopper 5 is installed at the bottom of the shear box 3, and the discharge hopper 5 is installed on the top of the support platform 6 through. The bottom is provided with storage box 13, and shear case 3 one side is provided with movable groove 12, and movable groove 12 is installed on support table 6 top, and movable groove 12 inside vertically is equipped with guide column 11, and guide column 11 top side is installed with Rack 10, the top of guide column 11 is provided with power box 1, power box 1 is provided with a number of heat dissipation holes 2 on both sides of the end away from guide column 11, and a second hand wheel 9 is installed on the side of power box 1 close to guide column 11 ;

[0042] A partition plate 32 is installed on the central axis of the power box 1, and a motor box 34 is provided on the side ...

Embodiment 2

[0046] see Figure 1-6 As shown, the present embodiment is a preparation process of an asphalt mixture, which includes the following raw materials in parts by weight: 90 parts of base asphalt, 20 parts of rubber powder, 6 parts of styrene copolymer, 5 parts of tackifier, 3 parts of activator part, 1.5 parts of stabilizer, 1.0 part of Eucommia gum, 0.6 part of ultraviolet absorber, 0.3 part of asphalt modifier:

[0047] The asphalt mixture comprises the following steps:

[0048] Step 1: Weigh raw materials according to parts by weight, and set aside:

[0049] Step 2: Prepare modified asphalt additive:

[0050] S1: after rubber powder, styrene copolymer and eucommia gum are stirred and mixed uniformly, an activator is added and mixed uniformly to obtain a modifier mother liquor;

[0051] S2: Add tackifier, stabilizer, ultraviolet absorber, and asphalt modifier to the mother liquor of the modifier in order to mix, and mix evenly to obtain the first mixture, dissolve the first ...

Embodiment 3

[0059] see Figure 1-6 As shown, the present embodiment is a preparation process of asphalt mixture, which includes the following raw materials in parts by weight: 100 parts of base asphalt, 25 parts of rubber powder, 8 parts of styrene copolymer, 6 parts of tackifier, 5 parts of activator part, 2.5 parts of stabilizer, 2 parts of Eucommia gum, 1.0 part of ultraviolet absorber, 0.4 part of asphalt modifier;

[0060] The asphalt mixture comprises the following steps:

[0061] Step 1: Weigh raw materials according to parts by weight, and set aside:

[0062] Step 2: Prepare modified asphalt additive:

[0063] S1: after rubber powder, styrene copolymer and eucommia gum are stirred and mixed uniformly, an activator is added and mixed uniformly to obtain a modifier mother liquor;

[0064] S2: Add tackifier, stabilizer, ultraviolet absorber, and asphalt modifier to the mother liquor of the modifier in order to mix, and mix evenly to obtain the first mixture, dissolve the first mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elasticity | aaaaa | aaaaa |

| elasticity | aaaaa | aaaaa |

| elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com