A kind of processing method of cotton Tencel double-sided fleece fabric with improved fluff uniformity

A processing method and cotton tencel technology, applied in the field of fabric processing, can solve the problems of different lengths of hairiness on the cloth surface, strong damage to the fabric, etc., and achieve the effects of simple process, plump hair feeling, and high pile uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

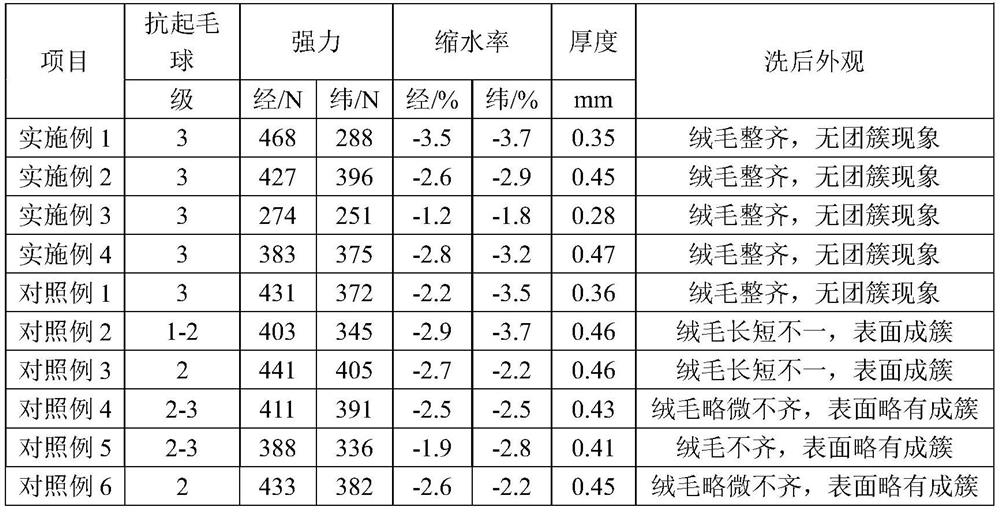

Examples

Embodiment 1

[0021] Gray fabric specification: 106” / 32s*21s / 133*60, 30% cotton 70% Tencel, 1 / 3 twill, weft surface coverage 75%.

[0022] The gray cloth goes through the following processes in turn:

[0023] (1) Singeing: Slightly singeing on the front, with a speed of 115 m / min.

[0024] (2) Enzymatic desizing: amylase 8g / L, stack at 55°C for 7 hours, then wash with hot water for 5 times.

[0025] (3) Rebleaching: 100% hydrogen peroxide 2g / L, sodium carbonate 5g / L, hydrogen peroxide stabilizer 5g / L, chelating dispersant 5g / L, steam with saturated steam for 50min, then wash with hot water for 4 times.

[0026] (4) Soft finishing: bulking agent 10g / L, urea 20g / L, setting temperature 140°C, vehicle speed 35 m / min.

[0027] (5) Brushing: the front side is brushed twice, the reverse side is brushed once, and the sequence of brushing is the front, the back, and the front. Among them, the front napping method is as follows: the speed of the clockwise roller is 220 rpm, and the pressure of the...

Embodiment 2

[0032] On the basis of Example 1, the difference from Example 1 is: gray fabric specification: 106” / 32s*32s / 2 / 133*65, 50% cotton 50% Tencel, 1 / 5 satin weave, weft surface coverage was 83%.

[0033] The difference in method steps (1)~(8) is:

[0034] (1) The speed of singeing is 120 m / min;

[0035] (2) Amylase 10g / L, stack at 60°C for 6h, and then wash with hot water for 5 times.

[0036] (3) Rebleaching: 100% hydrogen peroxide 4g / L, hydrogen peroxide stabilizer 8g / L, chelating dispersant 8g / L, and the rest are the same.

[0037] (4) Soft finishing: bulking agent 15g / L, triethanolamine 15g / L, setting temperature 150°C, vehicle speed 40 m / min.

[0038] (5) Napping: The front napping method is as follows: the speed of the clockwise roller is 200 rpm, and the pressure of the clockwise roller is 0.1Mpa; The cylinder speed is 80 rpm, the cloth feeding speed is 15 m / min, and the tension of the cloth guide roller is 2.0%. The method of napping on the reverse side is: the rotation...

Embodiment 3

[0043] On the basis of Example 1, the difference from Example 1 is: Gray fabric specification: 106" / 40s*40s / 133*72, 70% cotton 30% tencel, 1 / 2 twill, weft surface coverage rate is 66% .

[0044] The difference in method steps (1)~(8) is:

[0045] (1) The speed of singeing is 110 m / min.

[0046] (2) Enzyme desizing: amylase 5g / L, stack at 50°C for 8h.

[0047] (3) Rebleaching: 100% hydrogen peroxide 6g / L, hydrogen peroxide stabilizer 10g / L, chelating dispersant 10g / L.

[0048] (4) Soft finishing: fluffing agent 20g / L, glycerol 5g / L, urea 10g / L, setting temperature 130°C, vehicle speed 30 m / min.

[0049] (5) Napping: The front napping method is as follows: the speed of the clockwise roller is 250 rpm, and the pressure of the clockwise roller is 0.15Mpa; The cylinder speed is 90 rpm, the cloth feeding speed is 25 m / min, and the tension of the cloth guide roller is 2.5%. The method of napping on the reverse side is: the rotation speed of the clockwise roller is 500 rpm, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com