Broadband plasmon composite structure and preparation method thereof

A technology of plasmons and composite structures, which is applied in the fields of nanomaterials, optoelectronic materials, and optoelectronics, can solve the problems of low degree of freedom in laser wavelength selection, low sensitivity, uniformity, and low reliability, and achieve good consistency and improved The effect of detection sensitivity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

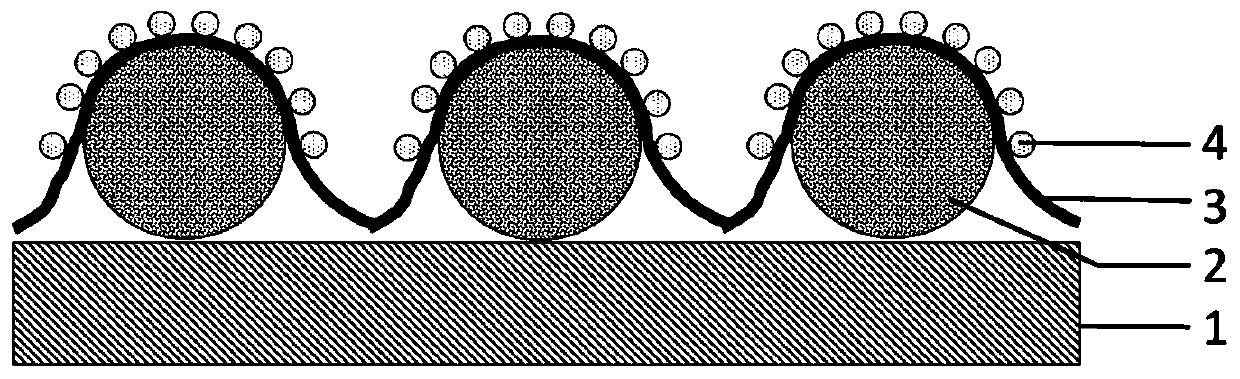

[0030] A method for preparing a broadband plasmonic composite structure, comprising the following steps:

[0031] (1) Depositing a metal film or metal nanoparticle layer on the surface of the substrate;

[0032] The substrate is formed from any suitable material, including:

[0033] Insulators: such as glass, quartz, ceramics (such as alumina), etc.;

[0034] Semiconductors: such as silicon, GaN, GaAs, etc.;

[0035] Silicon-on-insulator (SOI);

[0036] Composite material of SOI, silicon and metal.

[0037] The material of metal thin film or metal nano particle layer can be gold, silver, copper, aluminum, alloy or mixture, and described alloy is the alloy that any two or more forms of gold, silver, copper, aluminum, and described mixture is gold, A mixture of two or more of silver, copper, and aluminum.

[0038] The deposition preparation method of metal thin film or metal nanoparticle layer includes physical vapor deposition method, chemical vapor deposition method, atom...

Embodiment 1

[0043] A composite structure for broadband surface-enhanced spectroscopy comprising the steps of:

[0044] (1) Depositing a metal film or metal nanoparticle layer on the surface of the substrate;

[0045] Select quartz glass as the substrate, and then deposit a gold nano-film on the substrate surface by evaporation method, with a film thickness of 1 nanometer.

[0046] (2) The two-dimensional material is transferred to the surface of the gold nanofilm by PMMA-assisted wet method, and the two-dimensional material is a single-layer graphene material;

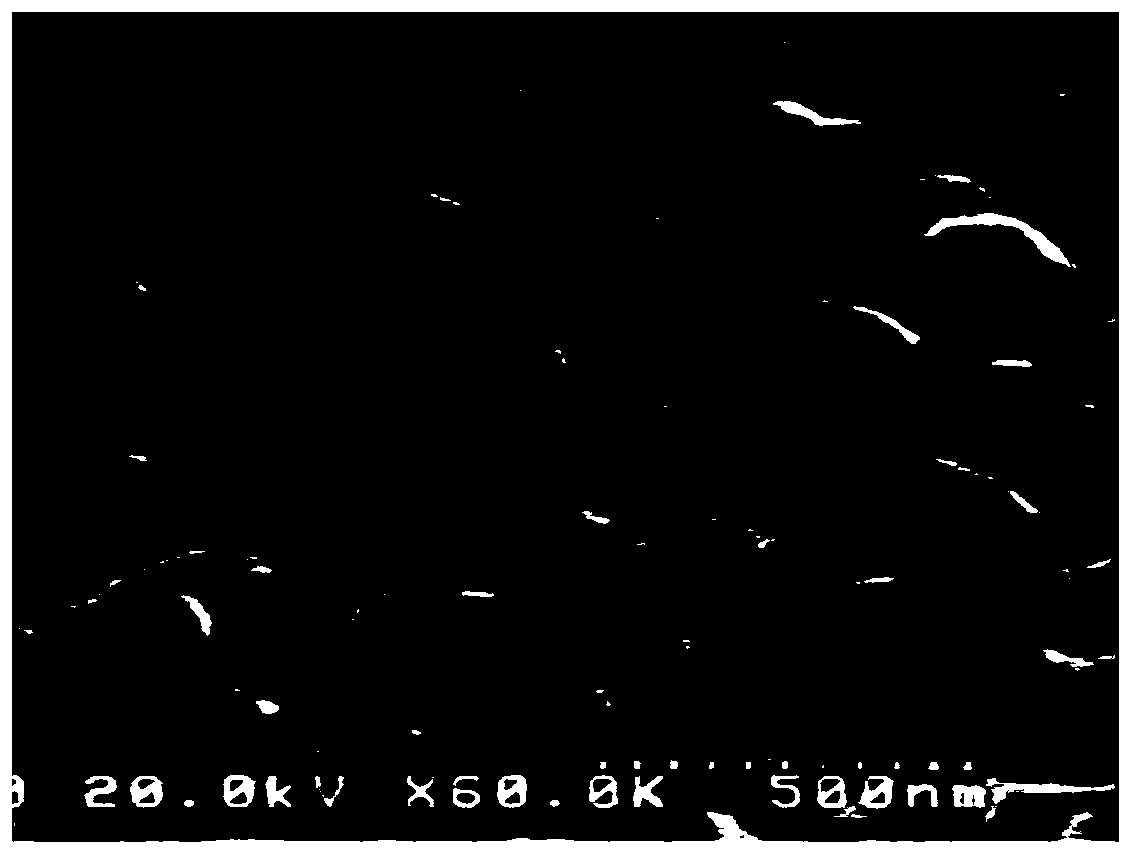

[0047] (3) High temperature annealing, the annealing temperature is 100°C. After high-temperature annealing, the metal nanofilm or the metal nanoparticle layer grows into a large-sized metal nanoparticle layer, and the size of the metal nanoparticle is 10 nanometers;

[0048] (4) Depositing small-sized gold nanoparticles, the small-sized nanoparticles are prepared by an evaporation method, and the size of the small-sized nanopar...

Embodiment 2

[0050] A method for preparing a broadband plasmonic composite structure, comprising the following steps:

[0051] (1) Depositing a metal film or nanoparticle layer on the surface of the substrate;

[0052] Select quartz glass as the substrate, and then use the evaporation method to deposit silver nano-film on the substrate, with a film thickness of 10 nanometers;

[0053] (2) Transfer the two-dimensional material to the surface of the silver nano film by dry method, and the two-dimensional material is a 2-4 layer graphene material;

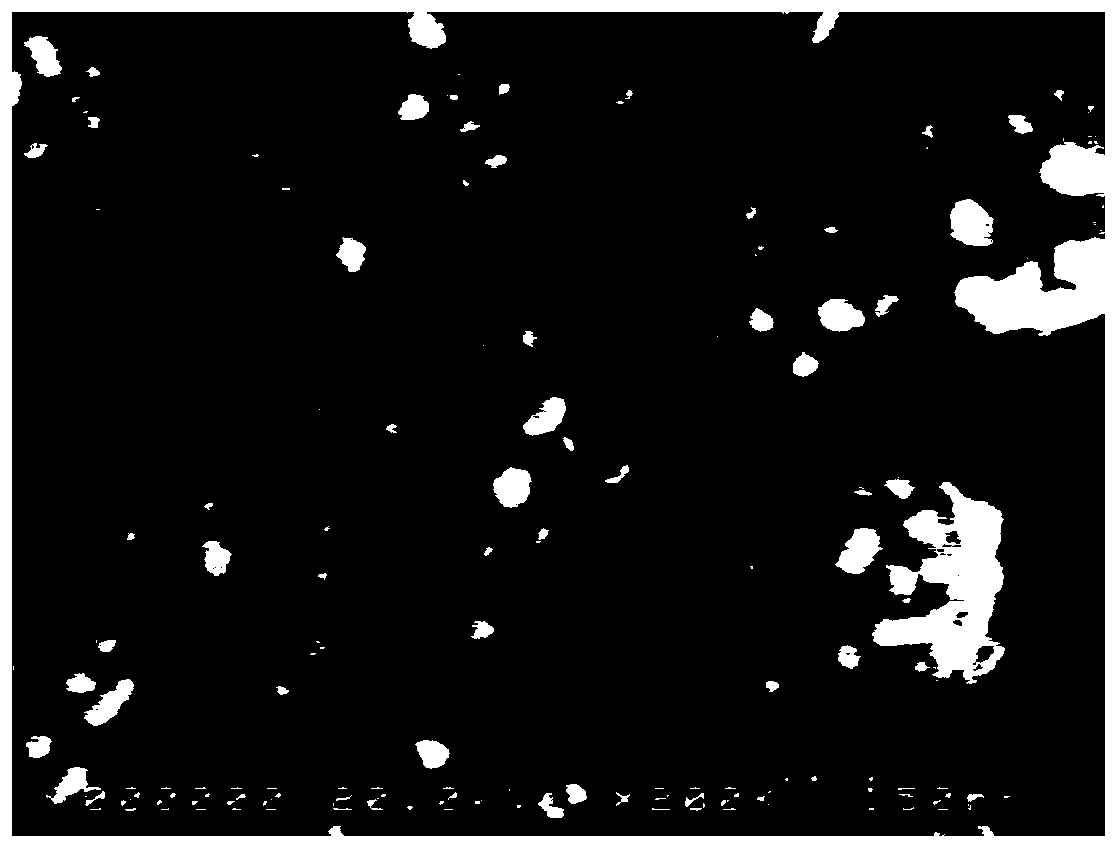

[0054] (3) High temperature annealing, the annealing temperature is 350°C. After high-temperature annealing, the metal nanofilm or the metal nanoparticle layer grows into a large-sized metal nanoparticle layer, and the size of the metal nanoparticle is 100 nanometers;

[0055] (4) Depositing small-sized silver nanoparticles, the small-sized nanoparticles are prepared by a gas aggregation method, and the size of the small-sized nanoparticles is 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com