Grounding device composite metal friction disc and production process thereof

A composite metal and grounding device technology, applied in the direction of connection, vehicle connectors, connection contact materials, etc., can solve the problems of poor dimensional stability, heavy friction disc weight, and easy cracks, etc., and achieve good wear resistance and electrical conductivity , good casting performance, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

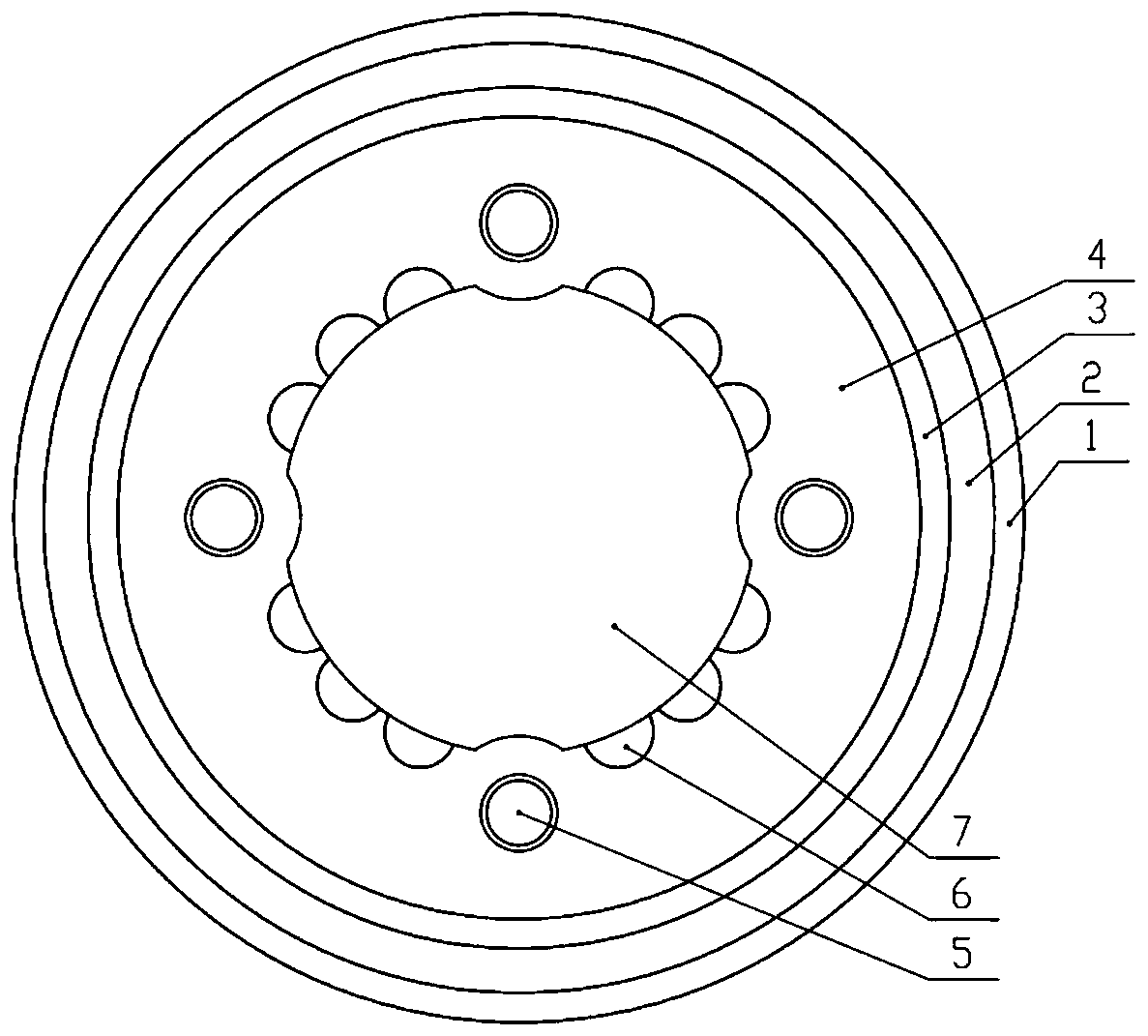

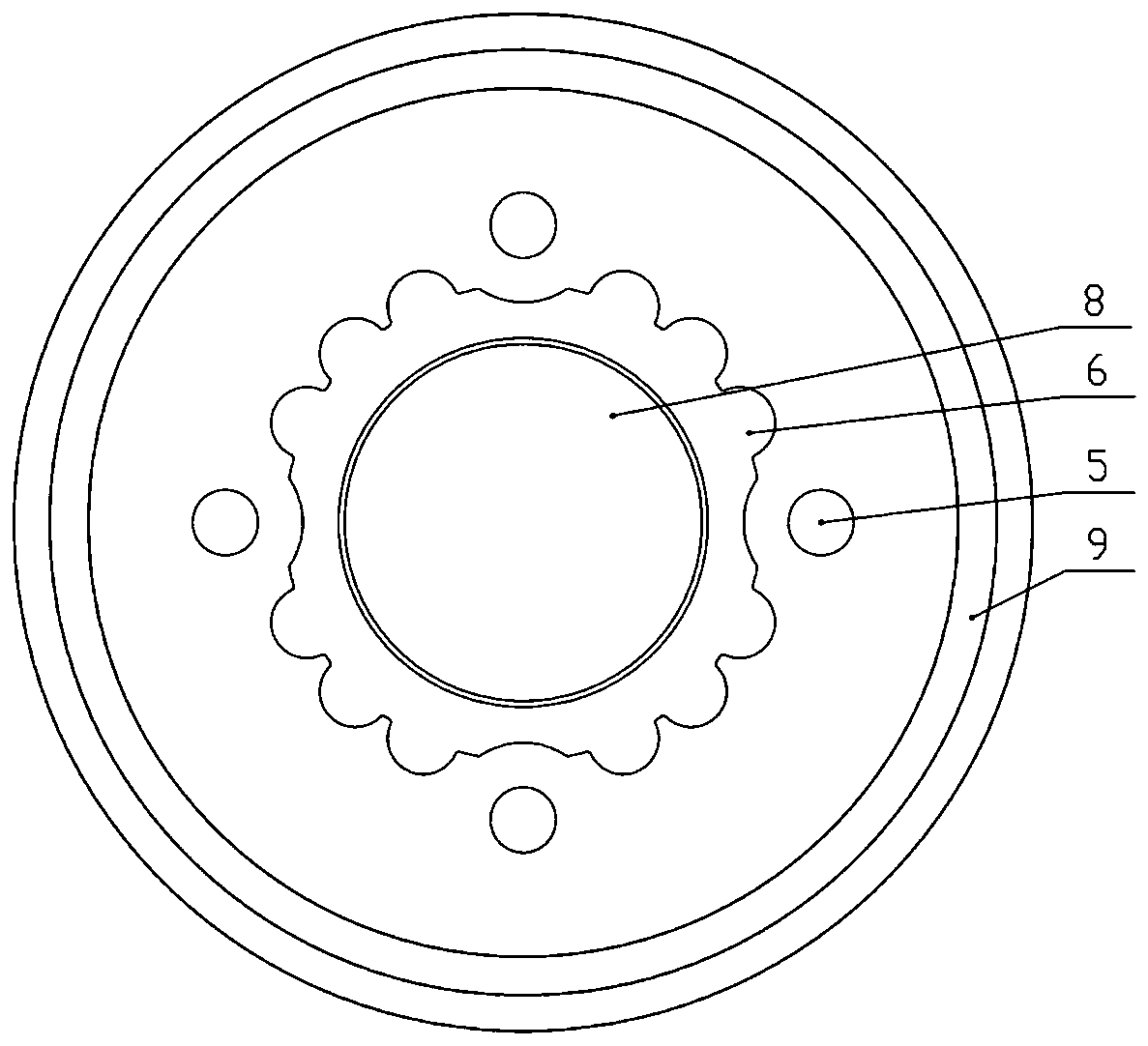

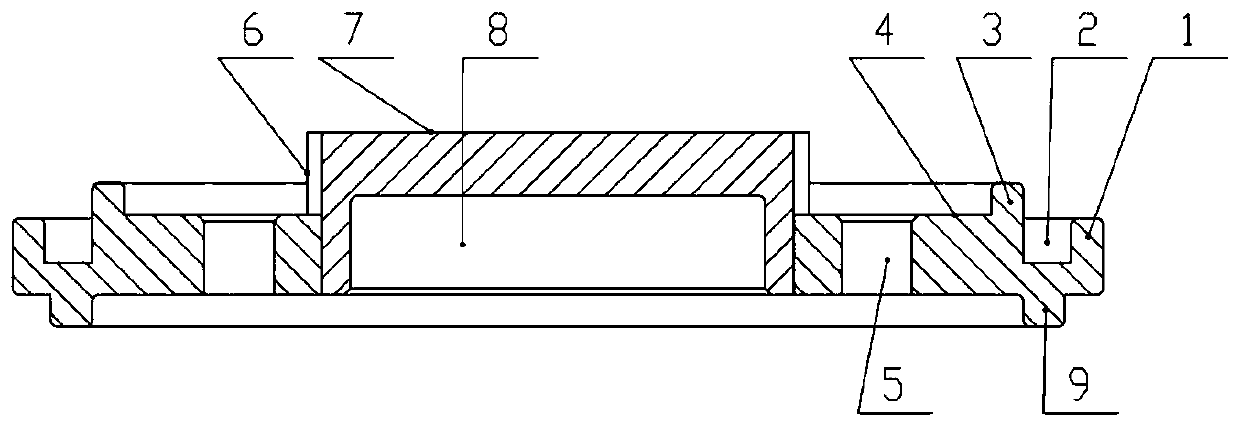

[0041] The production process of producing the above-mentioned a kind of grounding device composite metal friction disc, such as Figure 4 with 5 As shown, the specific steps are as follows:

[0042]In step 1, the copper liquid 10 and the aluminum liquid 12 are subjected to compound continuous casting through a double crystallizer continuous casting method to form a composite billet 14; the specific method is to use two coaxial crystallizers arranged along the direction of drawing the billet, first The prepared copper liquid 10 is solidified in the upper crystallizer to form a disk core blank 11, and the disk core blank 11 enters the aluminum liquid 12 in the lower heat preservation crucible, and then the aluminum liquid is solidified in the lower mold to form a wrapped layer embryo material 13, and then the cladding layer blank material 13 is metallurgically combined with the disk core blank material 11 to form a composite blank material 14, such as Figure 5 shown.

[004...

Embodiment 2

[0054] The production process of producing the described a kind of grounding device composite metal friction disc, such as Figure 4 with 5 As shown, the specific steps are as follows:

[0055] Step 1, metallurgically combining the copper liquid 10 and the aluminum liquid 12 through the double crystallizer continuous casting method to form a composite blank 14; The prepared copper liquid 10 is solidified in the upper crystallizer to form a disk core blank 11, and the disk core blank 11 enters the aluminum liquid 12 in the lower heat preservation crucible, and then the aluminum liquid solidifies in the lower mold to form a coating layer blank 13, then the cladding layer blank 13 is metallurgically combined with the disk core blank 11 to form a composite blank 14, such as Figure 5 shown.

[0056] Wherein, the chemical composition of the copper liquid 10 is Sn 8%, Zn 2%, Pb 1.5%, Ni 0.1%, P 0.04%, Ti 0.3% by mass fraction, the total impurity content is less than 0.2%, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Abrasion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap