Method for extracting cinnamyl aldehyde-rich composition from cinnamon leaves and device for extracting cinnamyl aldehyde-rich composition from cinnamon leaves

A technology of cinnamaldehyde and cinnamon leaves, applied in separation methods, chemical instruments and methods, solvent extraction, etc., can solve problems such as difficult to completely remove organic solvents, difficult separation of essential oils, and low cinnamaldehyde content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Leaves of Cinnamomum cassia were washed, dried, and then crushed into 1-10 mm pieces.

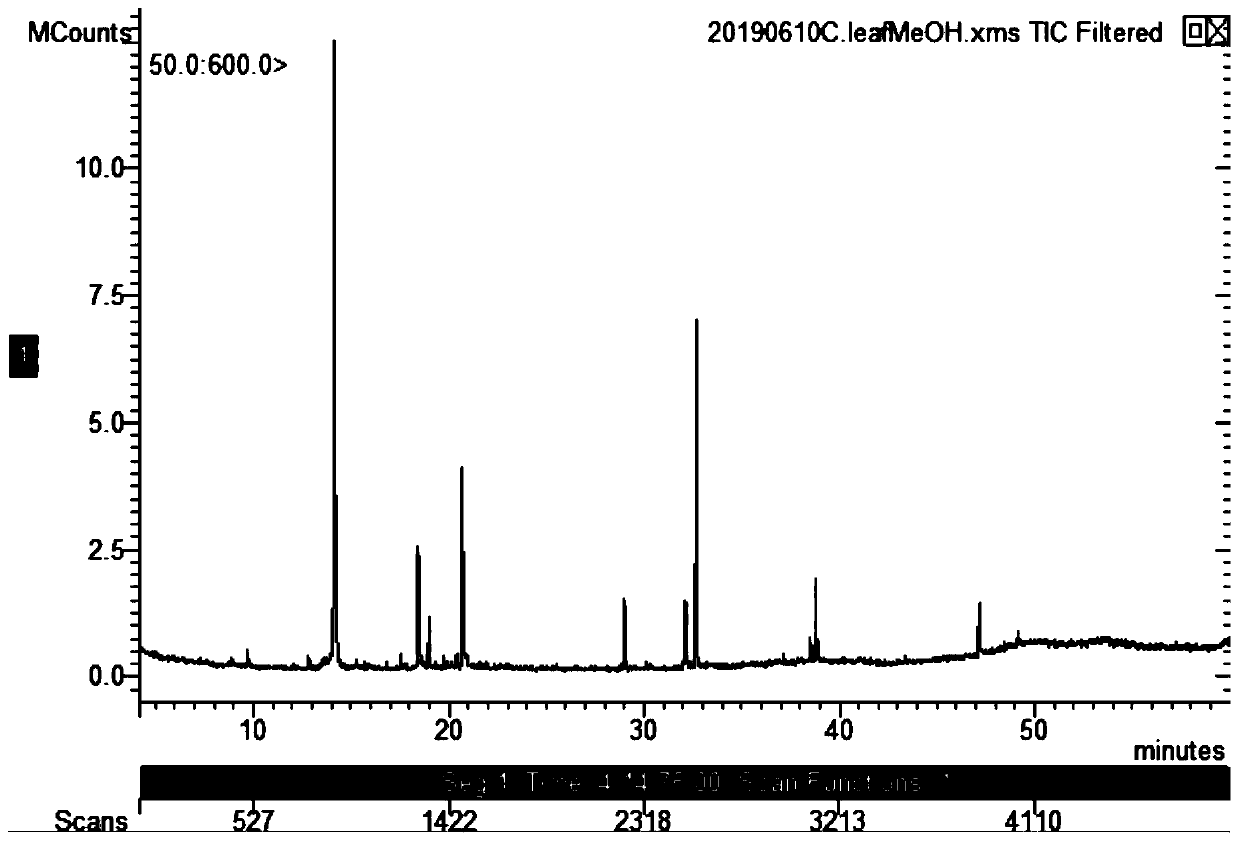

[0074] Weigh 350 grams of cinnamon leaf fragments, pour them into the extraction tank of the subcritical propane fluid extraction device, and then in order: determine the path of the pump, extraction tank, separation tank, etc. to empty the original air; inject propane with the same pressure as the propane storage tank (8 bar); set the extraction conditions as follows: propane flow rate 12 liters / hour, extraction tank pressure 45 bar / temperature 60°C, separation tank pressure 8-10 bar / temperature 50°C. Carry out propane subcritical extraction 2 hours with above-mentioned condition, obtain product 3.7 grams, its GC-MS collection of illustrative plates sees figure 1 , where the main components: cinnamaldehyde content of about 42%, the extraction rate of 86.3% (3.7x0.42 / 1.8); secondary components: o-methoxycinnamic aldehyde (o-methoxycinnamic aldehyde) about 11.2%, stearic acid formald...

Embodiment 2~13

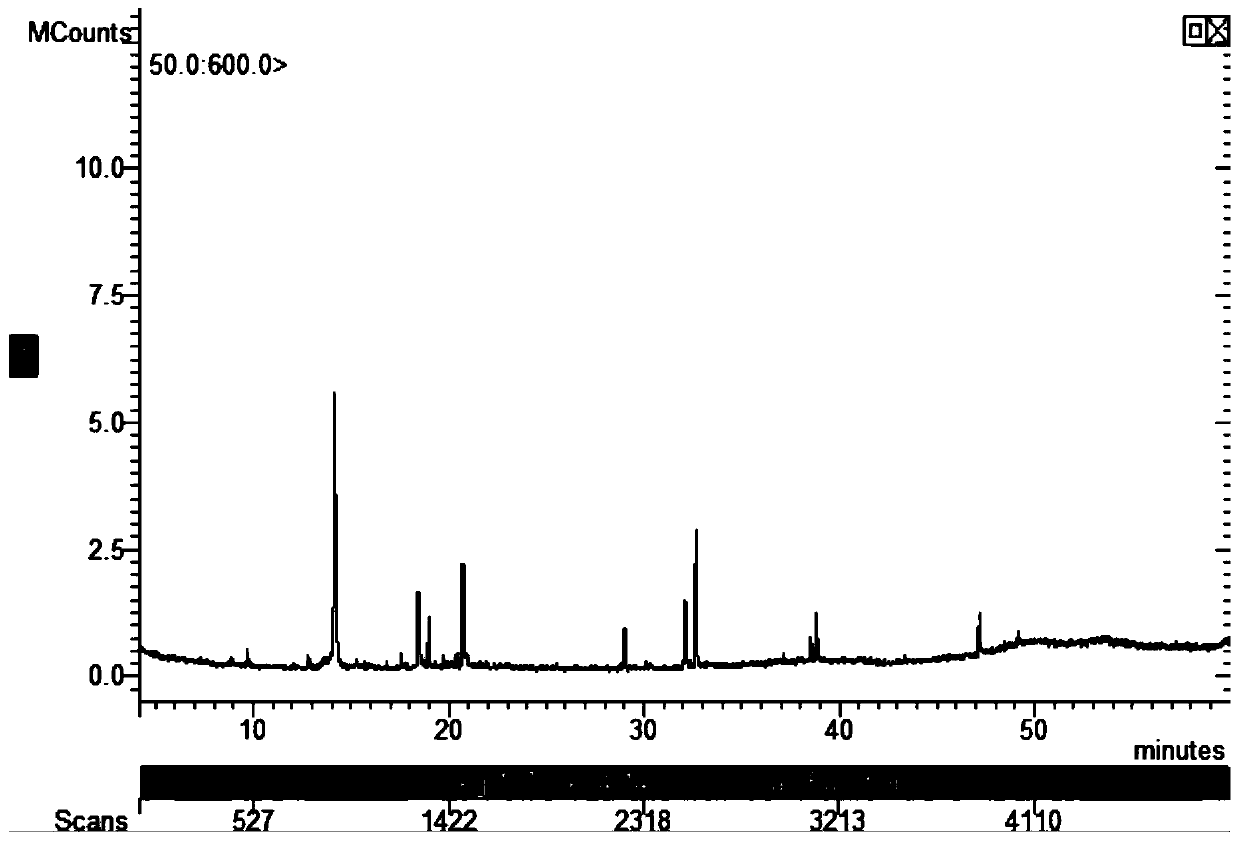

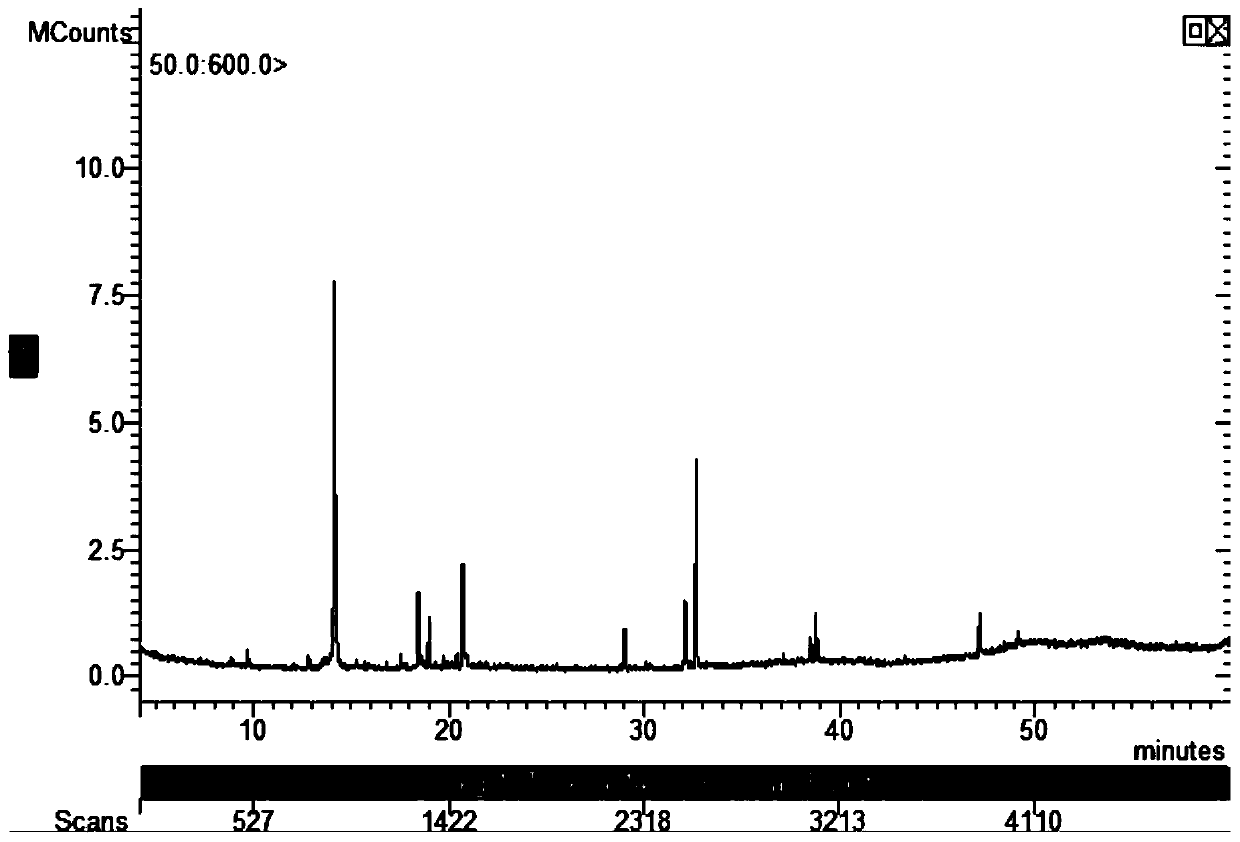

[0079] Similar to Preliminary Example 1, but the subcritical extraction conditions are slightly different, see Table 2, and the amount of the obtained product is also shown in Table 2 below. Wherein the GC-MS collection of illustrative plates of preliminary embodiment 8,9,12,13 see respectively figure 2 , 3, 4, 5, wherein the cinnamaldehyde content is about 36-42%, and the yield is about 2.5-3.5g.

[0080] Table 2: Propane flow rate (L / hr), extraction tank pressure (bar), extraction tank temperature (° C.), product weight (g) in preliminary examples 1 to 13.

[0081]

[0082]

[0083] There are 16 main components, minor components, and other detected components of preliminary examples 2 to 13, all of which are similar to those of preliminary example 1, and the ratio is also similar, with figure 2 , 3, 4, 5 and figure 1 comparison can be confirmed. Also, the content of cinnamaldehyde in preliminary example 8 is 36%, and the yield is 2.5%; the content of cinnamaldehy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com