Flue gas purification method for negative electrode material coating section

A flue gas purification process and a technology for negative electrode materials, which are applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of complex purification methods, reduce flue gas purification costs, and poor purification effects, and simplify flue gas. Purification process, reducing the cost of flue gas purification, and improving the effect of purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

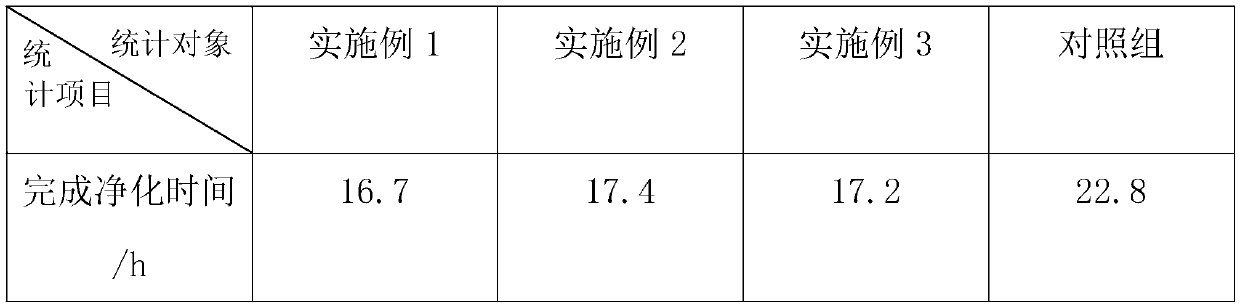

Embodiment 1

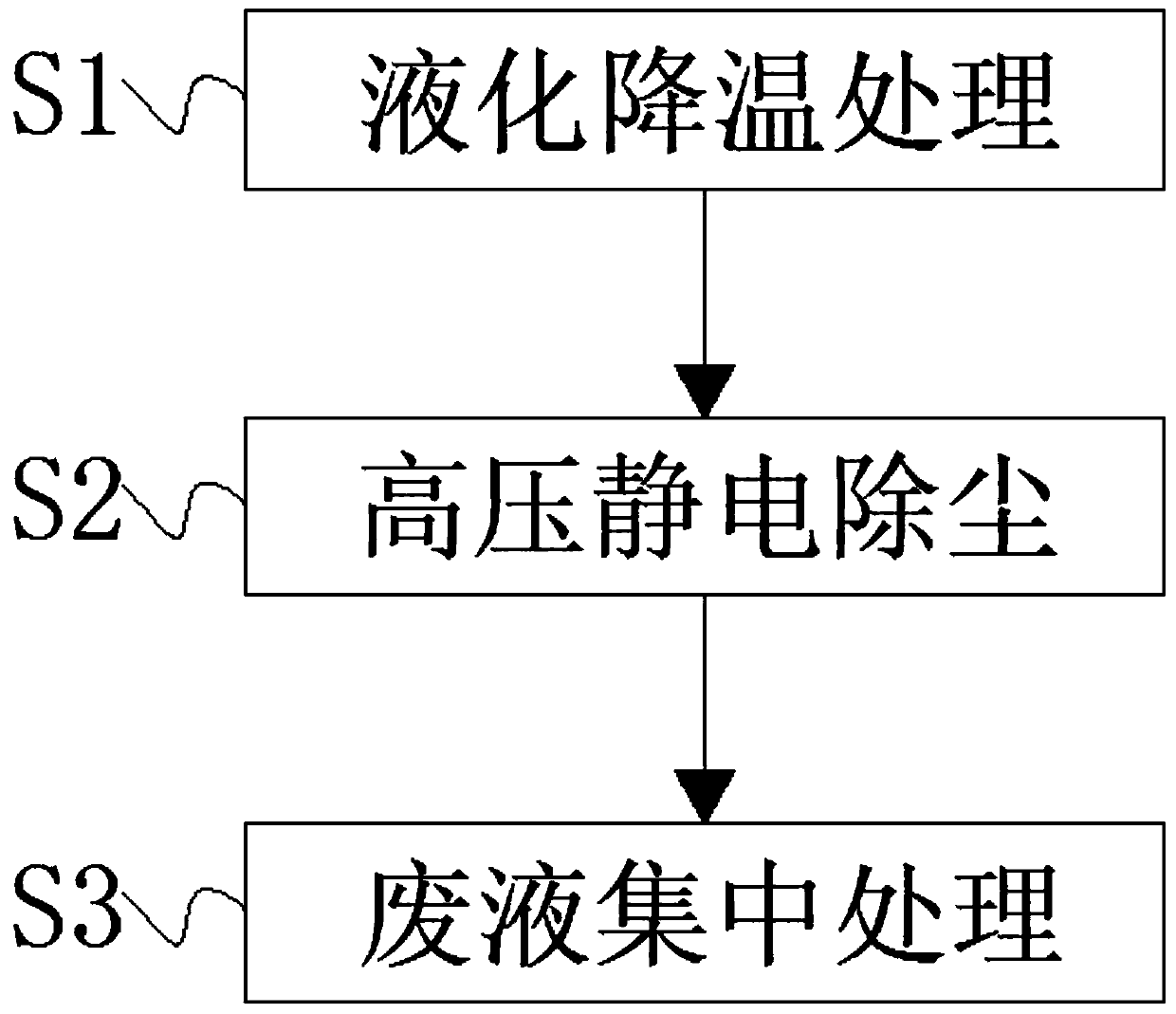

[0025] S1. Liquefaction and cooling treatment: firstly, the generated flue gas enters the pre-sedimentation dust collector in the form of negative pressure. The pre-settling dust collector is equipped with porous plate dust retention and flame arrester. At the same time, the high-pressure pump is started through the thermal control system to spray and atomize the industrial water through the nozzle to cool down, so as to play the role of fire resistance and cooling to remove large particles, and change the organic gas in the flue gas from gaseous to liquid. The model is SP- 6 negative pressure fans with an air volume of 11500m 3 / H, the rated power is 245W, the thermal control system includes temperature sensor, PLC controller, high pressure pump and electromagnetic throttle valve, the temperature sensor is fixedly installed on the inner wall of the dust collector, and the PLC controller and high pressure pump are fixedly installed with the dust collector On the shell of the P...

Embodiment 2

[0029] S1. Liquefaction and cooling treatment: firstly, the generated flue gas enters the pre-sedimentation dust collector in the form of negative pressure. At the same time, the high-pressure pump is started through the thermal control system to atomize the industrial water through the nozzle to cool down, so as to play the role of fire resistance and cooling to remove large particles, and change the organic gas in the flue gas from gaseous state to liquid state. The model is SP- 6 negative pressure fans with an air volume of 11000m 3 / H, the rated power is 240W, the thermal control system includes temperature sensor, PLC controller, high pressure pump and electromagnetic throttle valve, the temperature sensor is fixedly installed on the inner wall of the dust collector, and the PLC controller and high pressure pump are fixedly installed with the dust collector On the shell of the PLC controller, the input end of the PLC controller is electrically connected to the output end ...

Embodiment 3

[0033] S1. Liquefaction and cooling treatment: firstly, the generated flue gas enters the pre-sedimentation dust collector in the form of negative pressure. The pre-settling dust collector is equipped with porous plate dust retention and flame arrester. At the same time, the high-pressure pump is started through the thermal control system to spray and atomize the industrial water through the nozzle to cool down, so as to play the role of fire resistance and cooling to remove large particles, and change the organic gas in the flue gas from gaseous to liquid. The model is SP- 6 negative pressure fans with an air volume of 12000m 3 / H, the rated power is 250W, the thermal control system includes temperature sensor, PLC controller, high pressure pump and electromagnetic throttle valve, the temperature sensor is fixedly installed on the inner wall of the dust collector, and the PLC controller and high pressure pump are fixedly installed with the dust collector On the shell of the P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com