Method for treating xanthate-containing heavy metal flotation wastewater

A technology of flotation wastewater and treatment method, applied in mining wastewater treatment, water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of complex treatment steps, high operating cost, large energy consumption and chemical consumption, etc. Achieve the effect of recyclability, broad market prospects and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The processing method of the xanthate-containing heavy metal flotation wastewater of the present embodiment may further comprise the steps:

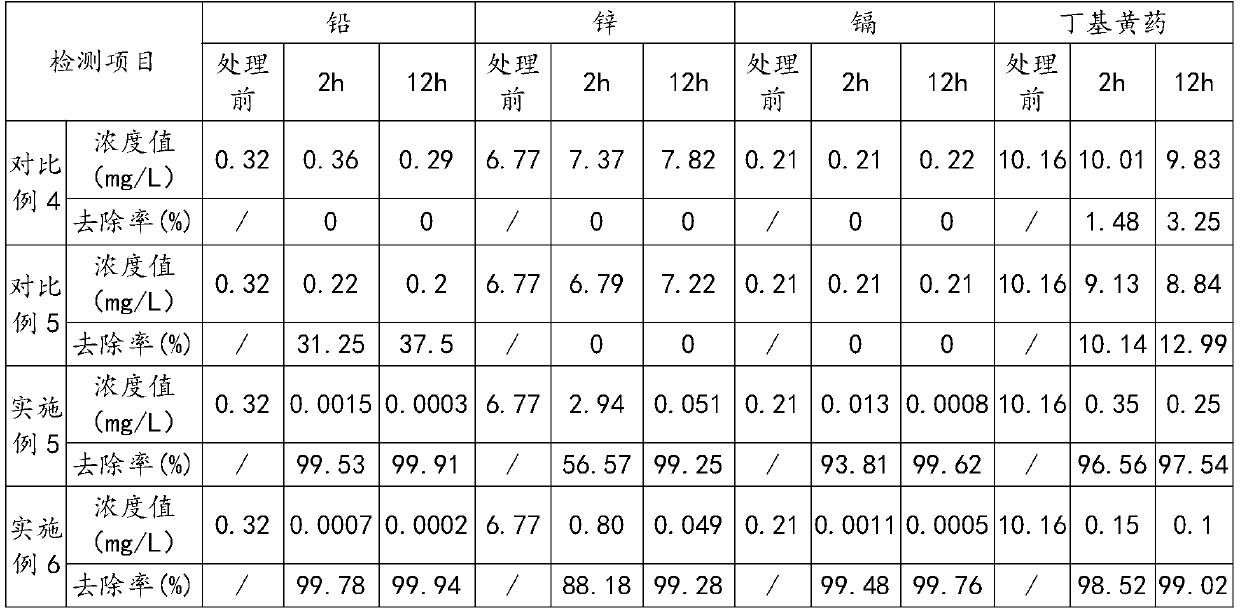

[0036] Take iron filings with a particle size of 0.075mm-0.83mm, and add them to the flotation wastewater to be treated at a weight ratio of 0.5:1000. In the flotation wastewater to be treated, the content of xanthate is 10.16mg / L, the content of heavy metal lead is 0.32mg / L, the content of heavy metal zinc is 6.77mg / L, and the content of heavy metal cadmium is 0.21mg / L.

[0037] Then stir, the stirring rate is 50r / min, and the time is 120min; aging for 6h, filtering to obtain filtrate and sediment respectively, the filtrate is the treated flotation wastewater, and the sediment is recycled. In the treated flotation wastewater, the content of xanthate is 0.1 mg / L, the content of heavy metal lead is 0.0003 mg / L, the content of heavy metal zinc is 0.049 mg / L, and the content of heavy metal cadmium is 0.0005 mg / L.

[0038] It can be...

Embodiment 2

[0040] The processing method of the xanthate-containing heavy metal flotation wastewater of the present embodiment may further comprise the steps:

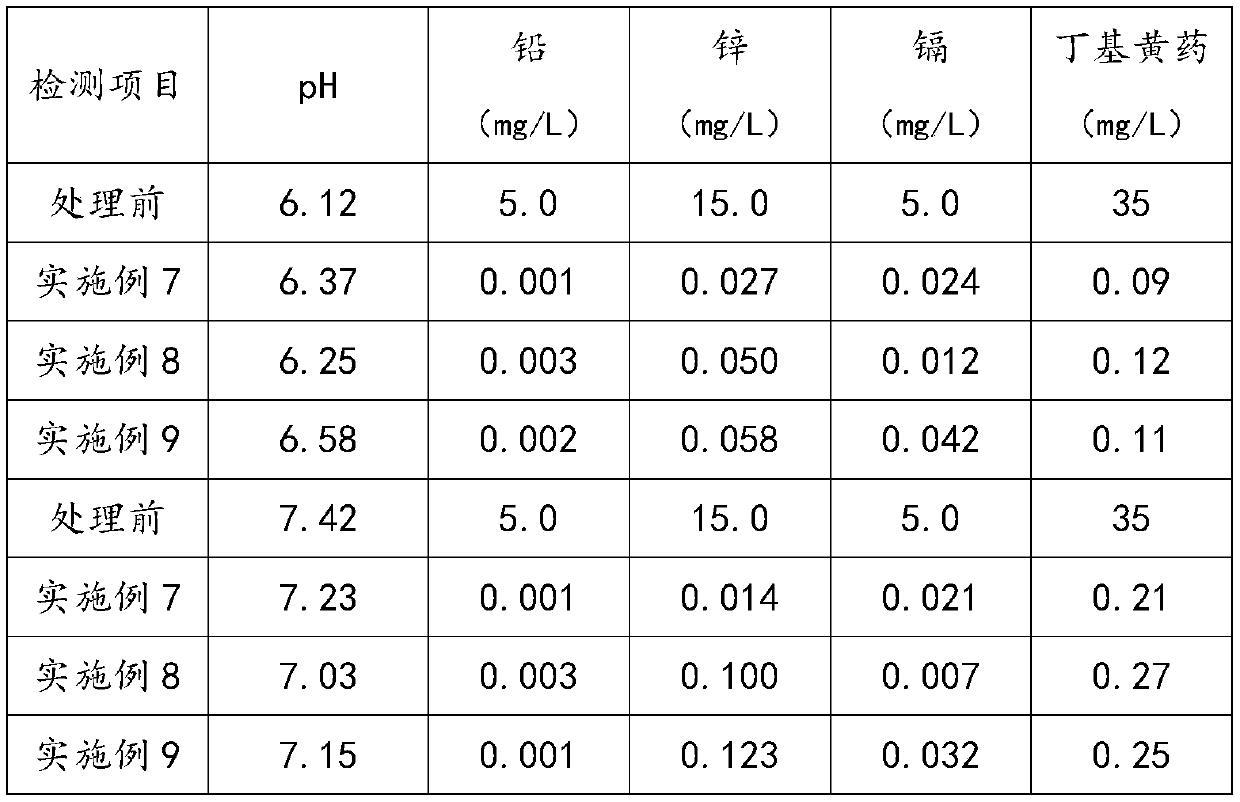

[0041]Take manganese dioxide with a particle size of 0.075mm-0.83mm, and add it to the flotation wastewater to be treated at a weight ratio of 1:1000. In the flotation wastewater to be treated, the content of xanthate is 25mg / L, the content of heavy metal lead is 5mg / L, the content of heavy metal zinc is 15mg / L, and the content of heavy metal cadmium is 4.9mg / L.

[0042] Then carry out aeration, the intensity of the aeration is 0.45m 3 / (m 2 min), the time is 90 minutes; aging for 15 hours, filtering to obtain the filtrate and sediment respectively, the filtrate is the treated flotation wastewater, and the sediment is recycled. In the treated flotation wastewater, the content of xanthate is 2.55 mg / L, the content of heavy metal lead is 0.001 mg / L, the content of heavy metal zinc is 0.027 mg / L, and the content of heavy metal cad...

Embodiment 3

[0045] The processing method of the xanthate-containing heavy metal flotation wastewater of the present embodiment may further comprise the steps:

[0046] Take iron particles with a particle size of 0.075mm-0.83mm, and add them to the flotation wastewater to be treated at a weight ratio of 10:1000. The content of xanthate in the flotation wastewater to be treated is 35mg / L , the content of heavy metal lead is 20mg / L, the content of heavy metal zinc is 20mg / L, and the content of heavy metal cadmium is 20mg / L.

[0047] Then stir, the stirring rate is 200r / min, and the time is 60min; aging for 24h, filtering to obtain filtrate and sediment respectively, the filtrate is the treated flotation wastewater, and the sediment is recycled. In the treated flotation wastewater, the content of xanthate is 0.27 mg / L, the content of heavy metal lead is 0.069 mg / L, the content of heavy metal zinc is 0.361 mg / L, and the content of heavy metal cadmium is 0.21 mg / L.

[0048] It can be seen that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com