Preparation method of ceramic matrix composite surface priming coat

A composite material and ceramic-based technology, which is applied in the field of preparation of the surface primer of ceramic-based composite materials, can solve the problems of increasing the service life of the composite surface coating system, low coating bonding strength, and short service life, and achieve physical performance matching , solve the effect of easy falling off and prolong life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The steps of the preparation method using the ceramic matrix composite material surface primer of the present invention are as follows:

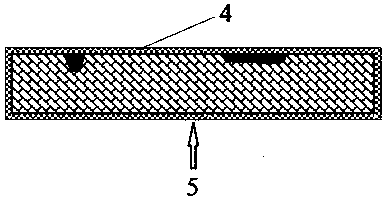

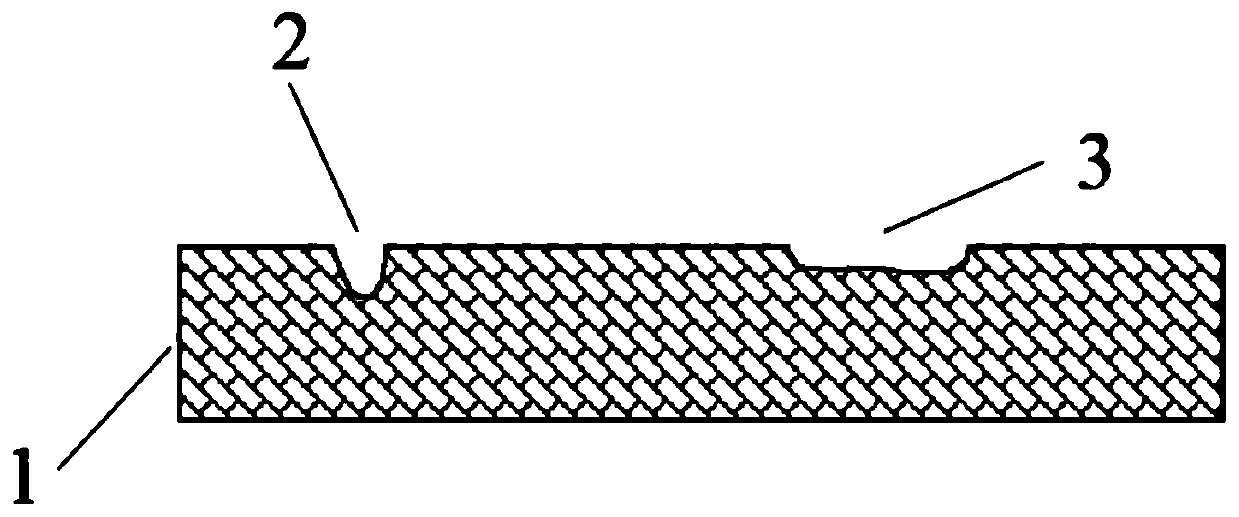

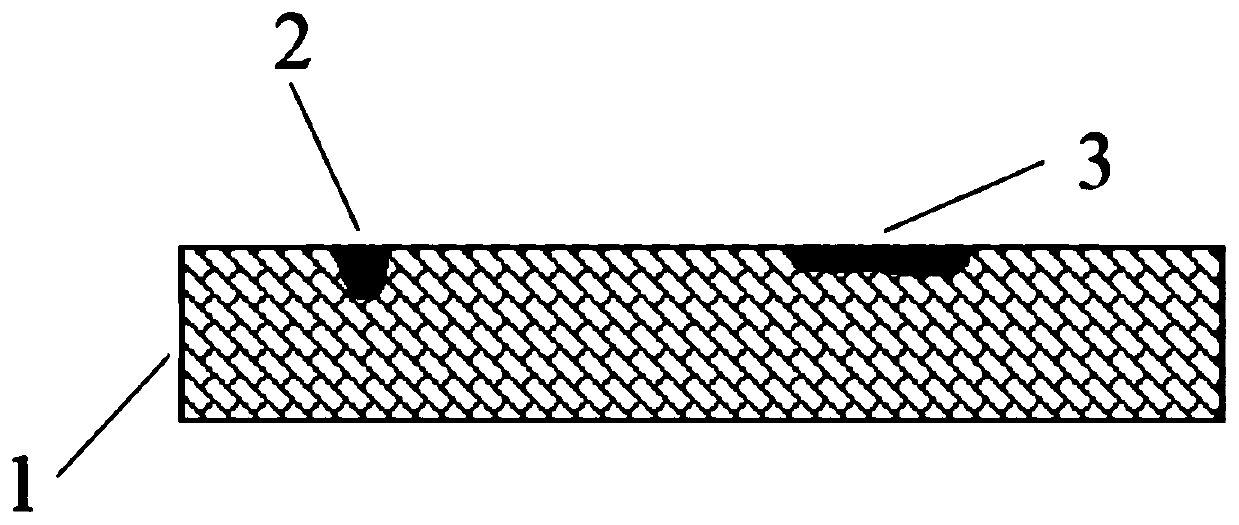

[0039] Step 1, see attached figure 1 As shown, the SiC / SiC and C / SiC composites 1 with small-area, deep-hole surface defects 2 and large-area, shallow-layer surface defects 3 were ultrasonically cleaned with deionized water until clean, and then cleaned with absolute ethanol and acetone for 30 minutes, and finally placed in an oven for 3 hours at 120°C, and then put the composite material 1 in a drying dish for later use;

[0040] Step 2: Prepare the polycarbosilane precursor solution: pour the solid polycarbosilane precursor and xylene with a SiC ceramic yield of 60% into the container according to the weight ratio of 1:1, and stir mechanically at room temperature until the solid polycarbosilane Carbosilane is completely dissolved;

[0041] Step 3. Prepare a slurry precursor for repairing small-area, deep-hole surface defects: firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com