Tin oxide modified sensor, preparation method thereof and application thereof in nitrogen oxide gas-sensitive detection

A sensor and gas sensor technology, applied to modified SnO2 sensor and its preparation, and the application field of nitrogen oxide gas detection, can solve the problems of thermal safety, high power consumption, sensor sensitivity reduction, etc., to improve sensitivity and Effect of Gas Sensitive Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] SnO 2 Preparation of / RGOH gas sensor:

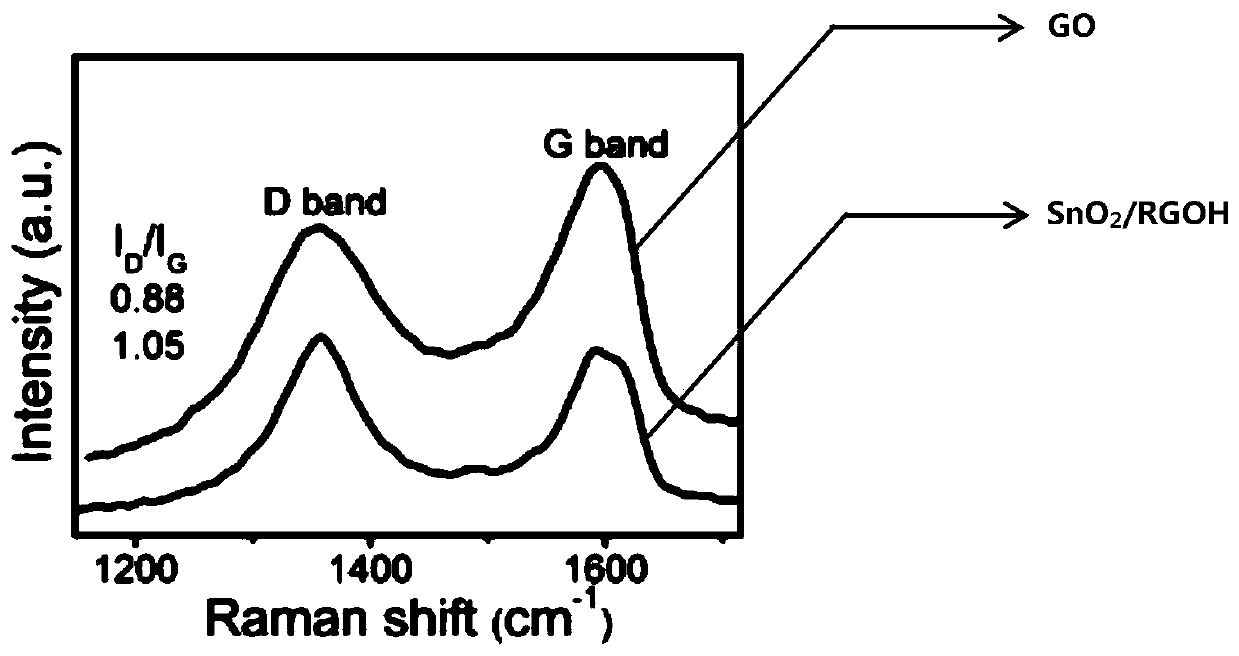

[0061] (1) 3D SnO 2 / Preparation of RGOH

[0062]Graphene is dispersed in deionized water to obtain 1mg / mL graphene aqueous solution, take 10mL graphene aqueous solution and add 90mg SnCl to it 2 2H 2 O, the mixture was sonicated for 10 min, sealed in an autoclave, and heated at 180 °C for 11 h to obtain 3D SnO 2 / RGOH.

[0063] (2) Preparation of chemical resistors

[0064] On Si / SiO 2 Substrate (260nm thick SiO on both sides 2 Layer 300μm silicon wafer) on the spin-coated photoresist, photolithography, sputtering 15nm Ti / 200nm Au layer and lift-off process, to obtain interdigital electrodes.

[0065] (3) Preparation of Micro Heater

[0066] Si / SiO used in said step (2) 2 On the other side of the substrate, photolithography, sputtering 15nm Ti / 300nm Pt layer and lift-off process were performed to obtain serpentine platinum microwires; then photolithography, sputtering 5nm Ti / 300nm Au layer and lift-off process were pe...

Embodiment 2

[0071] Flexible SnO 2 Preparation of / RGOH gas sensor:

[0072] (1) 3D SnO 2 / Preparation of RGOH

[0073] Graphene is dispersed in deionized water to obtain 1mg / mL graphene aqueous solution, take 10mL graphene aqueous solution and add 90mg SnCl to it 2 2H 2 O, the mixture was sonicated for 10 min, sealed in an autoclave, and heated at 180 °C for 11 h to obtain 3D SnO 2 / RGOH.

[0074] (2) Preparation of chemical resistors

[0075] Interdigital electrodes were obtained by spin-coating photoresist on the LCP film (using a 300 μm silicon wafer as the substrate) and then performing photolithography, sputtering 15nm Ti / 200 nm Au layer and lift-off process.

[0076] (3) Preparation of Micro Heater

[0077] Carry out photolithography, sputtering 15nm Ti / 300nm Pt layer and stripping process on the other side of the LCP film used in said step (2) to obtain serpentine platinum microwires; then carry out photolithography, sputtering 5nm Ti / 300nm Au layer and lift-off process, r...

Embodiment 3

[0082] SnO 2 Preparation of / RGOH gas sensor:

[0083] (1) 3D SnO 2 / Preparation of RGOH

[0084] Graphene is dispersed in deionized water to obtain 1mg / mL graphene aqueous solution, take 10mL graphene aqueous solution and add 90mg SnCl to it 2 2H 2 O, the mixture was sonicated for 10 min, sealed in an autoclave, and heated at 180 °C for 10 h to obtain 3D SnO 2 / RGOH.

[0085] (2) Preparation of chemical resistors

[0086] On Si / SiO 2 Substrate (260nm thick SiO on both sides 2 Layer 300μm silicon wafer) on the spin-coated photoresist, photolithography, sputtering 15nm Ti / 200nm Au layer and lift-off process, to obtain interdigital electrodes.

[0087] (3) Preparation of Micro Heater

[0088] Si / SiO used in said step (2) 2 On the other side of the substrate, photolithography, sputtering 15nm Ti / 300nm Pt layer and lift-off process were performed to obtain serpentine platinum microwires; then photolithography, sputtering 5nm Ti / 300nm Au layer and lift-off process were p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com