P-GaN/AlGaN/GaN enhanced device based on fin-shaped gate structure and manufacturing method thereof

A gate structure and enhanced technology, which is applied in the field of p-GaN/AlGaN/GaN enhanced devices and their fabrication, can solve the problems of not meeting the application requirements of GaN-based electronic devices, poor device reliability and stability, and small forward threshold voltage issues such as good process repeatability and temperature stability, enhanced gate control capability, and high threshold voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

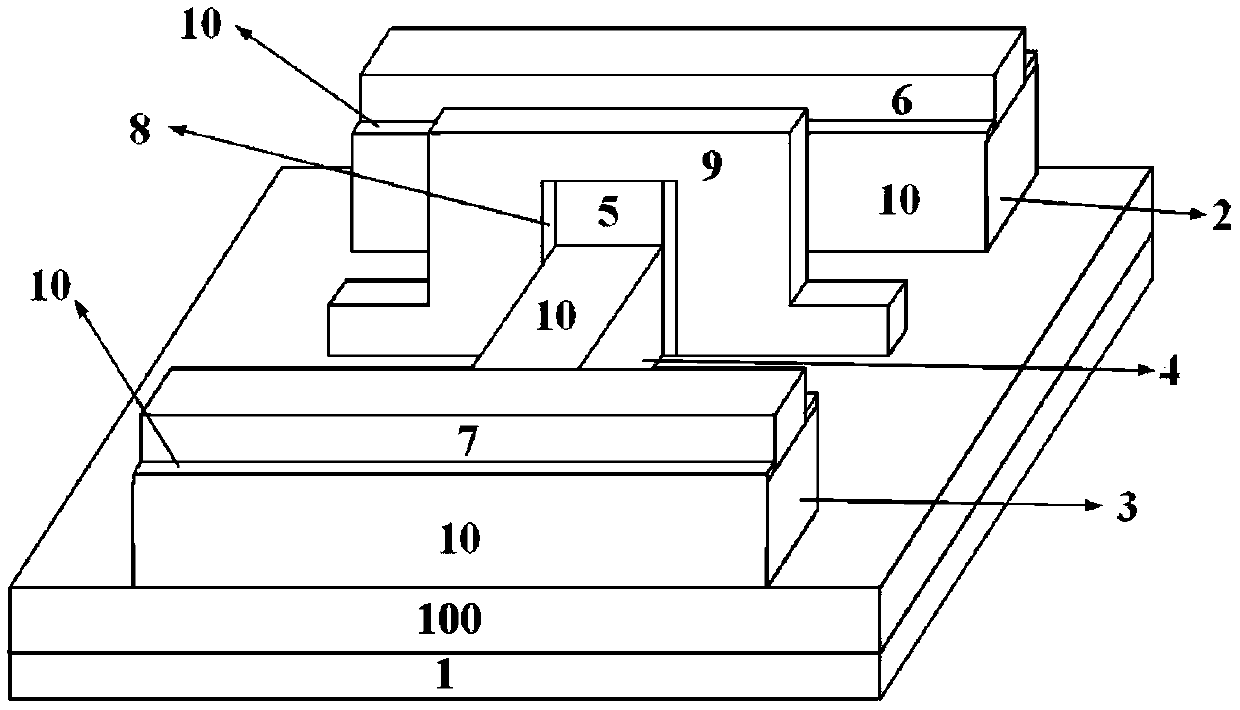

[0056] refer to figure 1 , figure 1 A schematic diagram of a p-GaN / AlGaN / GaN enhancement device based on a fin-shaped gate structure provided by an embodiment of the present invention.

[0057] An embodiment of the present invention provides a p-GaN / AlGaN / GaN enhanced device based on a fin-shaped gate structure, including:

[0058] substrate layer 1;

[0059] The source part 2 is located on one side of the upper layer of the substrate layer 1;

[0060] The drain part 3 is located on the other side of the upper layer of the substrate layer 1 and is opposite to the source part 2;

[0061] a Fin structure 4 located on the upper layer of the substrate layer 1 and located between the source part 2 and the drain part 3;

[0062] A cap layer 5, located on the upper layer in the middle of the Fin structure 4;

[0063] The source electrode 6 is located on the upper layer of the source part 2;

[0064] The drain electrode 7 is located on the upper layer of the drain part 3;

[00...

Embodiment 2

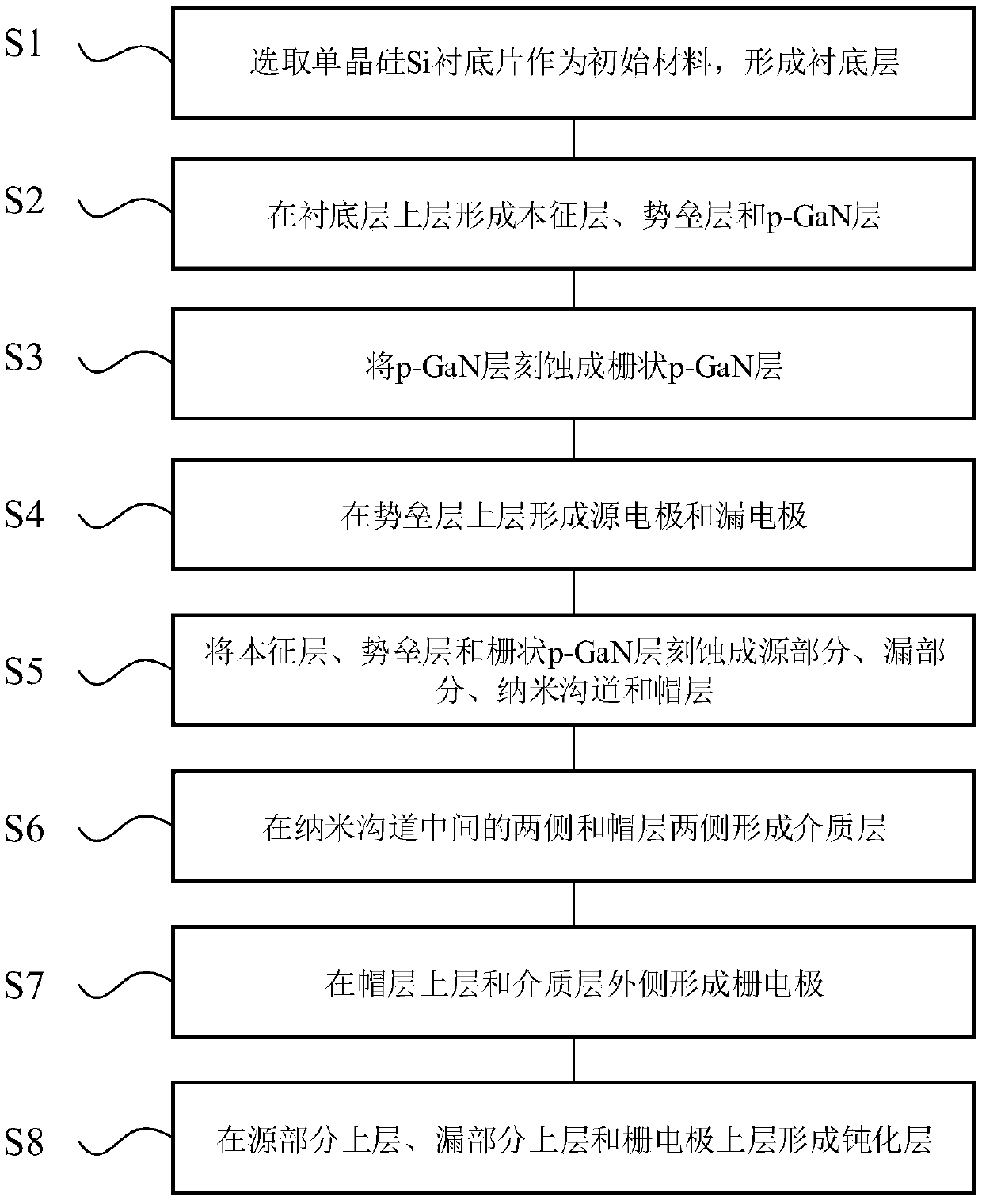

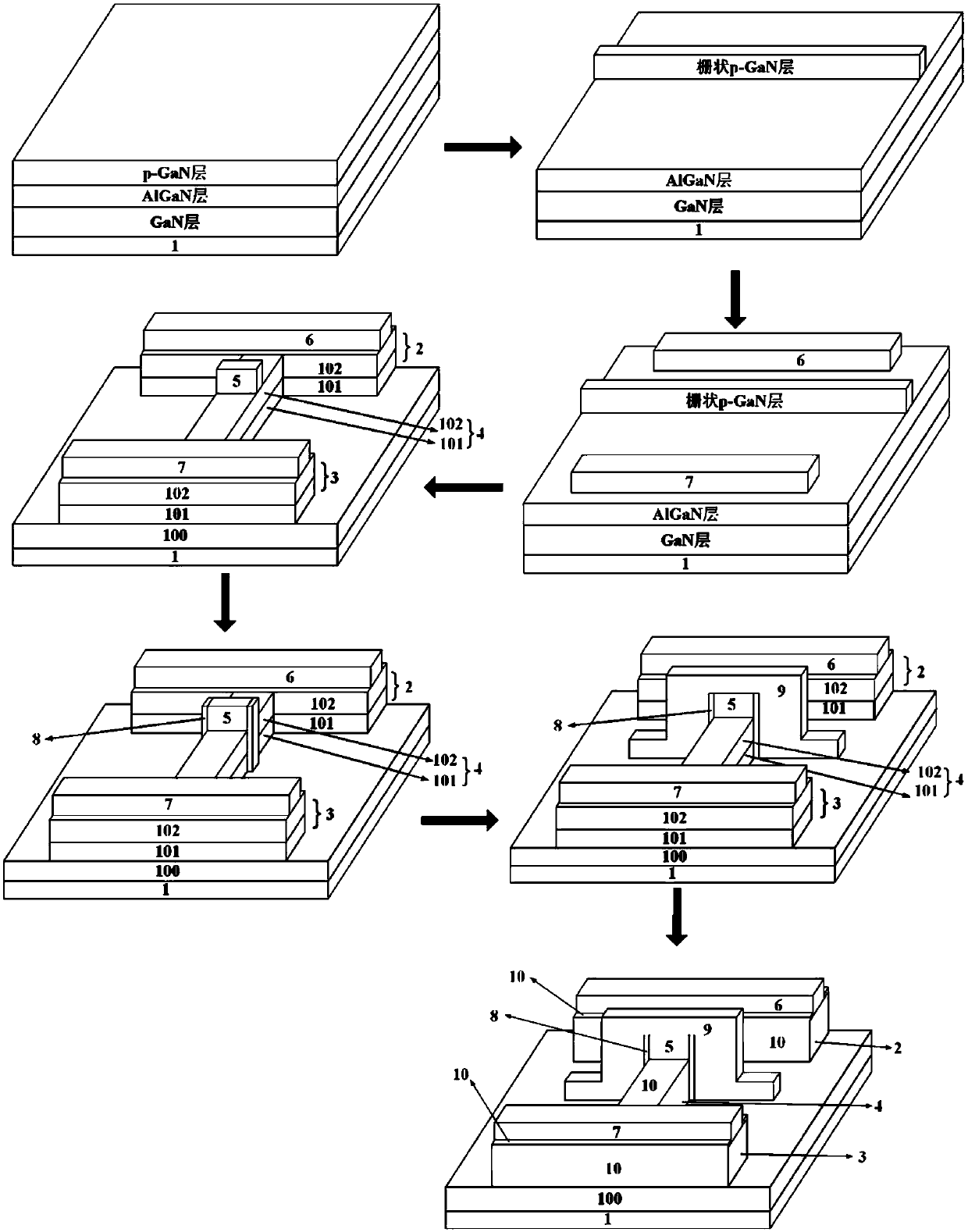

[0081] refer to figure 2 and image 3 , figure 2 A schematic flowchart of a manufacturing method of a p-GaN / AlGaN / GaN enhancement device based on a fin-shaped gate structure provided by an embodiment of the present invention; image 3 It is a schematic diagram of a manufacturing method of a p-GaN / AlGaN / GaN enhancement device based on a fin-shaped gate structure provided by an embodiment of the present invention.

[0082] Another embodiment of the present invention provides a method for manufacturing a p-GaN / AlGaN / GaN enhanced device based on a fin-shaped gate structure, including:

[0083] S1. Selecting a single crystal silicon Si substrate as an initial material to form a substrate layer 1;

[0084] S2, forming a GaN layer, an AlGaN layer and a p-GaN layer on the substrate layer 1;

[0085] S3. Etching the p-GaN layer into a gate-shaped p-GaN layer;

[0086] S4, forming a source electrode 6 and a drain electrode 7 on the upper layer of the AlGaN layer;

[0087] S5, et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com