Ceramic shell, method for processing surface thereof, and electronic equipment

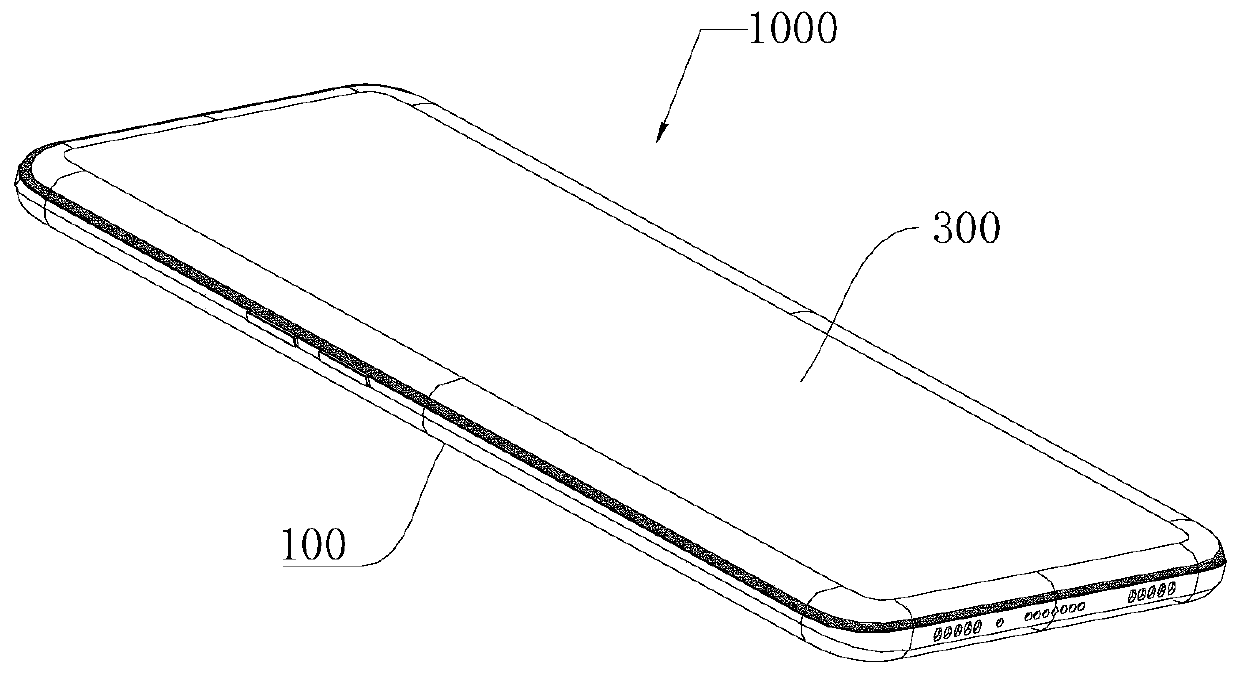

A technology for ceramic shells and processing methods, which is applied in the field of ceramic processing and can solve problems such as surface processing of ceramic shells that needs to be further studied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

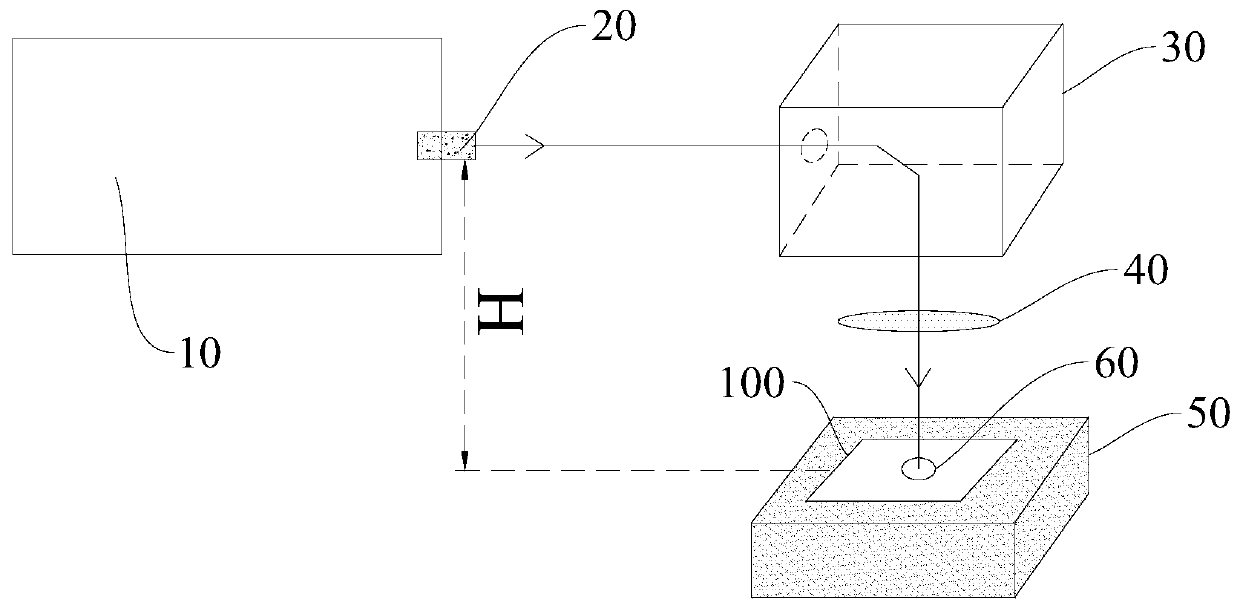

Method used

Image

Examples

preparation example Construction

[0017] Preparation of ceramic blanks: mixing ceramic raw material powders and binders, and then adopting injection molding, tape casting or dry pressing to obtain ceramic green blanks. Among them, according to the type of ceramics, at least one of alumina powder, zirconia powder and zirconium nitride powder can be used, and the purity of the ceramic raw material powder is above 99.99%; the binder can use paraffin wax, polyethylene glycol, stearic acid , one or more of dioctyl phthalate, polyethylene, polypropylene, polymethyl methacrylate, and polyoxymethylene. Based on the total weight of the above-mentioned ceramic raw material powder and binder, the content of the ceramic raw material powder is 70wt% to 99wt%, and the content of the binder is 1wt% to 30wt%. The specific content value can be determined according to the selected ceramic molding process. allow.

[0018] Degumming: put the ceramic blank in the degumming box for degumming or degreasing, the degumming temperatur...

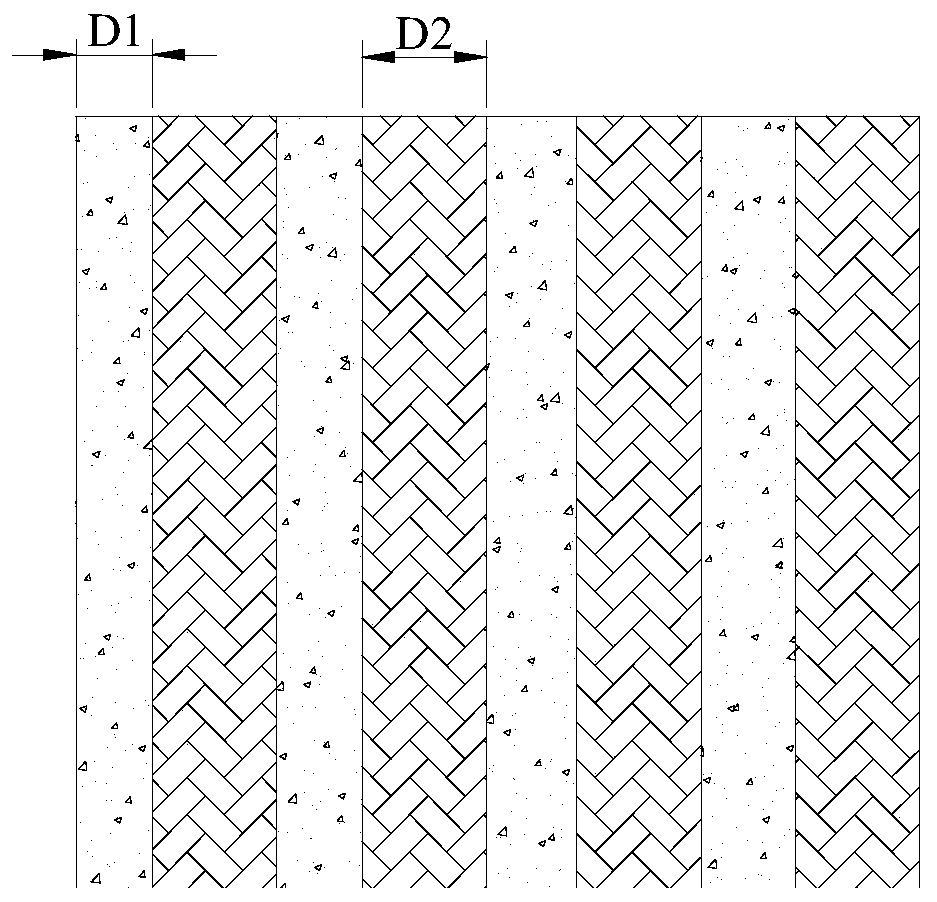

Embodiment 1

[0040] The steps of ceramic shell preparation and surface processing are the same as in Example 1, the difference is that when laser engraving texture patterns, the processing power of the carbon dioxide laser is 3W, and the processing rate of the carbon dioxide laser is 0.2mm / s.

[0041] The textured pattern on the outer surface of the processed ceramic shell has a depth of 0.005 mm, and the ceramic shell has no cracks during processing, and the color of the ceramic surface is uniform.

Embodiment 2

[0043] The steps of preparation and surface processing of the ceramic shell are the same as those in Embodiment 1, the difference being that the processing power of the carbon dioxide laser is 8W and the processing rate of the carbon dioxide laser is 1.0mm / s when the laser is engraving the texture pattern.

[0044] The textured pattern on the outer surface of the processed ceramic shell has a depth of 0.01 mm, and the ceramic shell has no cracks during processing, and the color of the ceramic surface is uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Spot diameter | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com