A kind of fine-grain tailings surface curing agent and its application method

A technology of fine-grain tailings and surface solidification, which is applied in the field of environmental engineering, can solve the problems of wind migration of heavy metals and environmental hazards, and achieve the effects of improved curing effect, low curing cost and short curing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

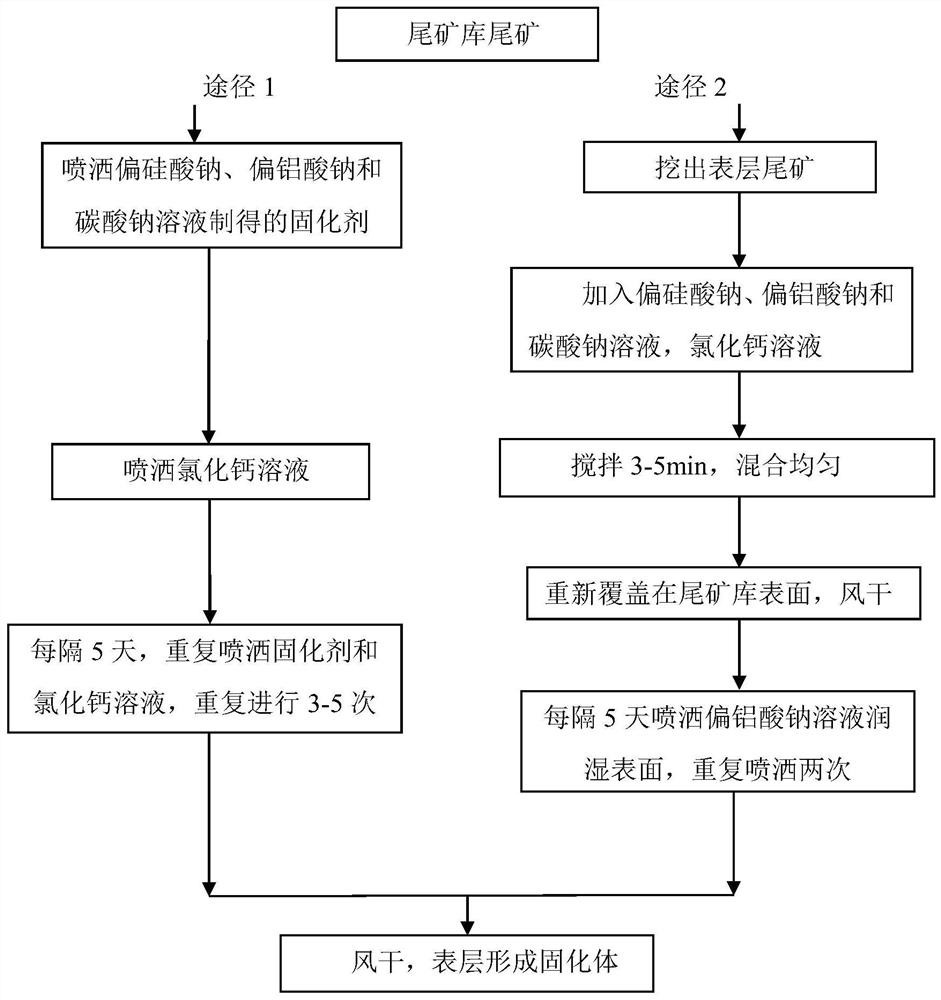

[0035] Embodiment 1 of the present invention is the surface solidification method of gold tailings, comprising the following:

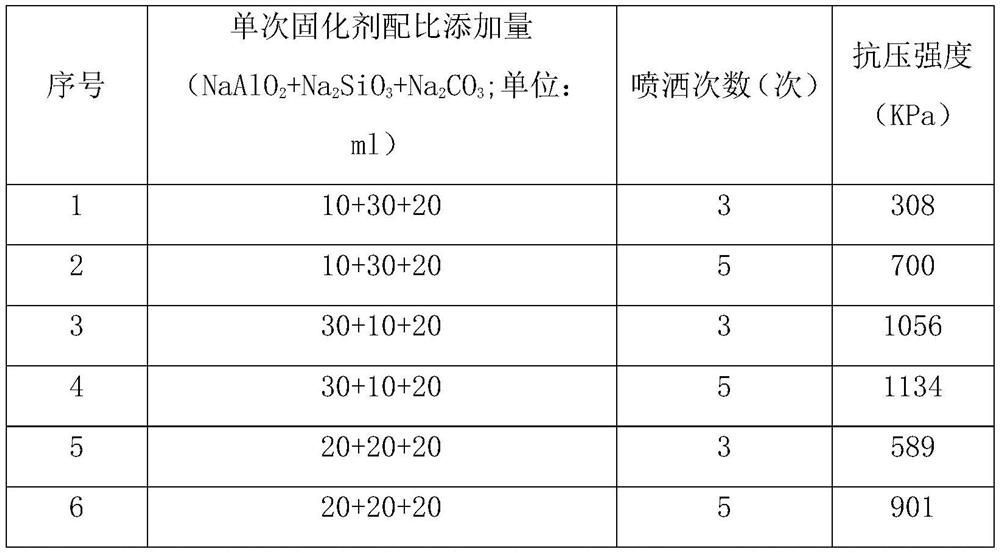

[0036] The solidified gold tailings particles come from the tailings pond of Xinda Gold Mine in Baotou, Inner Mongolia. The content of the tailings with a particle size of 2 Solution+30ml Na 2 SiO 3 Solution+20ml Na 2 CO 3 solution, ②30ml NaAlO 2 Solution+10ml Na 2 SiO 3 Solution+20ml Na 2 CO 3 solution, ③20ml NaAlO 2 Solution+20ml Na 2 SiO 3 Solution+20mlNa 2 CO 3 Solution, each component of each group of curing agent combination solution is sprayed 3 times and 5 times respectively, and the interval between two sprays is 5 days. After each spraying of the above mixed solution, 10ml of per 100g of tailings is sprayed Spray CaCl at a ratio of 240mM calcium chloride solution 2 Solution, after spraying the solution, the tailings were air-dried under natural drying conditions, and the compressive strength of the surface solidified body spraye...

Embodiment 2

[0040] Embodiment 2 of the present invention is the surface solidification method of copper tailings, comprising the following contents:

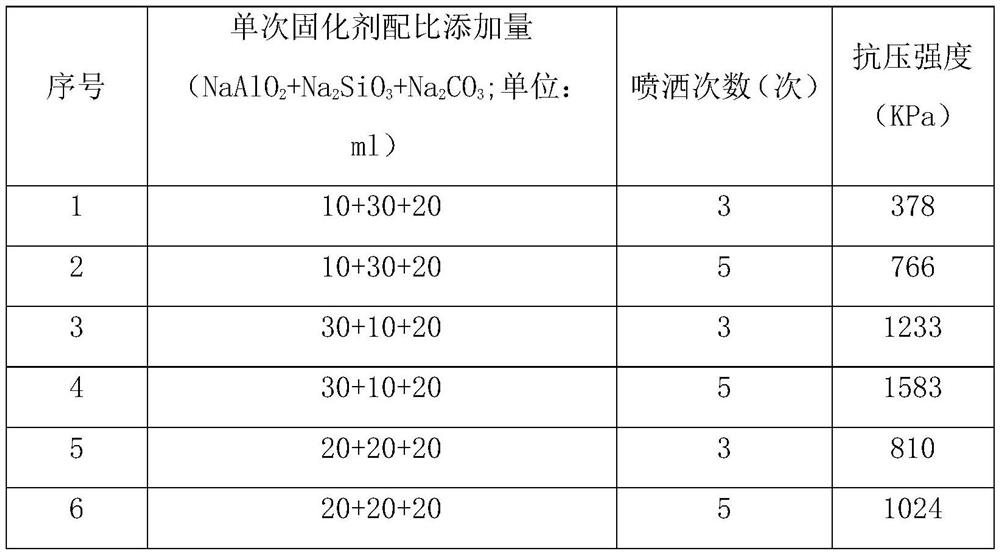

[0041] The solidified copper tailings particles come from the tailings pond of Zhongwei Copper Mine in Ningxia. The particle size of the tailings is all below 1mm, and the Si / Al molar ratio is 6.66; 1mol / L sodium metaaluminate solution, 1mol / L metaaluminate Sodium silicate solution, 1mol / L sodium carbonate solution, and anhydrous calcium chloride solid configuration concentration is 240mM calcium chloride solution to form the curing agent. According to the surface area of the tailings reservoir and the target solidification thickness to be obtained, spray 60ml of the mixed solution of sodium metaaluminate solution, sodium metasilicate solution and sodium carbonate solution per 100g of tailings; 2 Solution+30ml Na 2 SiO 3 Solution+20ml Na 2 CO 3 solution, ②30ml NaAlO 2 Solution+10ml Na 2 SiO 3 Solution+20ml Na 2 CO 3 solution, ③20...

Embodiment 3

[0045] Embodiment 3 of the present invention is the surface solidification method of gold tailings, comprising the following:

[0046] The solidified gold tailings come from the tailings pond of Xinda Gold Mine in Baotou, Inner Mongolia. The content of tailings with a particle size of 2 Solution+30ml Na 2 SiO 3 Solution+20ml Na 2 CO 3 solution, ②30ml NaAlO 2 Solution+10ml Na 2 SiO 3 Solution+20ml Na 2 CO 3 solution, ③20ml NaAlO 2 Solution+20ml Na 2 SiO 3 Solution+20ml Na 2 CO 3 Solution, the remaining 10ml in each ratio is calcium chloride solution; the ratio of adding 100ml of curing agent is: ④ 20ml NaAlO 2 Solution+40mlNa 2 SiO 3 Solution+30ml Na 2 CO 3 solution, ⑤40ml NaAlO 2 Solution+20ml Na 2 SiO 3 Solution+30ml Na 2 CO 3 solution, ⑥30ml NaAlO 2 Solution+30ml Na 2 SiO 3 Solution+30ml Na 2 CO 3 solution, the remaining 10ml in each proportion is calcium chloride solution, add the curing agent of the above proportion in the tailings, then fully sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com