Foam skeleton reinforced organic aerogel and preparation method thereof

A foam skeleton and aerogel technology, applied in the field of composite materials, can solve the problems of difficult industrialization, high cost, complex supercritical system, etc., and achieve the effects of good compressibility, low cost, and controllable microscopic morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

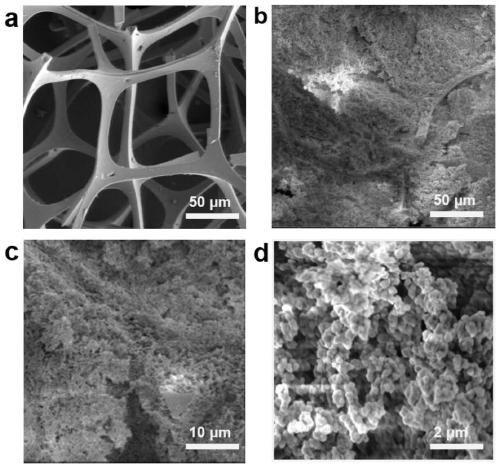

[0052] A kind of preparation method of the organic airgel that foam skeleton strengthens, comprises the following steps:

[0053] Add phenol, formaldehyde and hydrochloric acid in the reactor to react, the molar ratio of phenol to formaldehyde is 1:1, and the hydrochloric acid is 5% molar weight of phenol, to obtain a light yellow viscous liquid; adjust the temperature to 90°C to continue the reaction, and adjust When the pH is 7, vacuumize to obtain a phenolic resin. Then weigh a certain amount of phenolic resin and isopropanol respectively, add them into the stirring tank, stir mechanically until they are completely dissolved, finally add hexamethylenetetramine, and continue stirring for 1 hour to obtain a phenolic resin impregnation solution, in which the phenolic resin, isopropyl alcohol The mass ratio of propanol and hexamethylenetetramine is 10:90:2, and the mass fraction of phenolic resin is 10%.

[0054] Set the density to 10kg / m 3 The melamine foam is laid flat in a...

Embodiment 2

[0056] A kind of preparation method of the organic airgel that foam skeleton strengthens, comprises the following steps:

[0057] Add phenol, formaldehyde and hydrochloric acid in the reactor to react, the molar ratio of phenol to formaldehyde is 1:1, and the hydrochloric acid is 5% molar weight of phenol, to obtain a light yellow viscous liquid; adjust the temperature to 90°C to continue the reaction, and adjust When the pH is 7, vacuumize to obtain a phenolic resin. Then weigh a certain amount of phenolic resin and isopropanol respectively, add them into the stirring tank, stir mechanically until they are completely dissolved, finally add hexamethylenetetramine, and continue stirring for 1 hour to obtain a phenolic resin impregnation solution, in which the phenolic resin, isopropyl alcohol The mass ratio of propanol and hexamethylenetetramine is 10:90:2, and the mass fraction of phenolic resin is 10%.

[0058] Set the density to 20kg / m 3 The melamine foam is laid flat in a...

Embodiment 3

[0060] A kind of preparation method of the organic airgel that foam skeleton strengthens, comprises the following steps:

[0061] Add phenol, formaldehyde and hydrochloric acid in the reactor to react, the molar ratio of phenol to formaldehyde is 1:1, and the hydrochloric acid is 5% molar weight of phenol, to obtain a light yellow viscous liquid; adjust the temperature to 90°C to continue the reaction, and adjust When the pH is 7, vacuumize to obtain a phenolic resin. Then weigh a certain amount of phenolic resin and isopropanol respectively, add them into the stirring tank, stir mechanically until they are completely dissolved, finally add hexamethylenetetramine, and continue stirring for 1 hour to obtain a phenolic resin impregnation solution, in which the phenolic resin, isopropyl alcohol The mass ratio of propanol and hexamethylenetetramine is 15:85:3, and the mass fraction of phenolic resin is 15%.

[0062] Set the density to 10kg / m 3 The melamine foam is laid flat in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com