Long-horizontal-section horizontal well cementation curable prepad fluid and application thereof

A technology for horizontal sections and horizontal wells, which is applied in the field of curable prefluid for long horizontal section horizontal well cementing, which can solve the problems of lack of density and achieve the effect of inhibiting mudstone and meeting the needs of cementing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

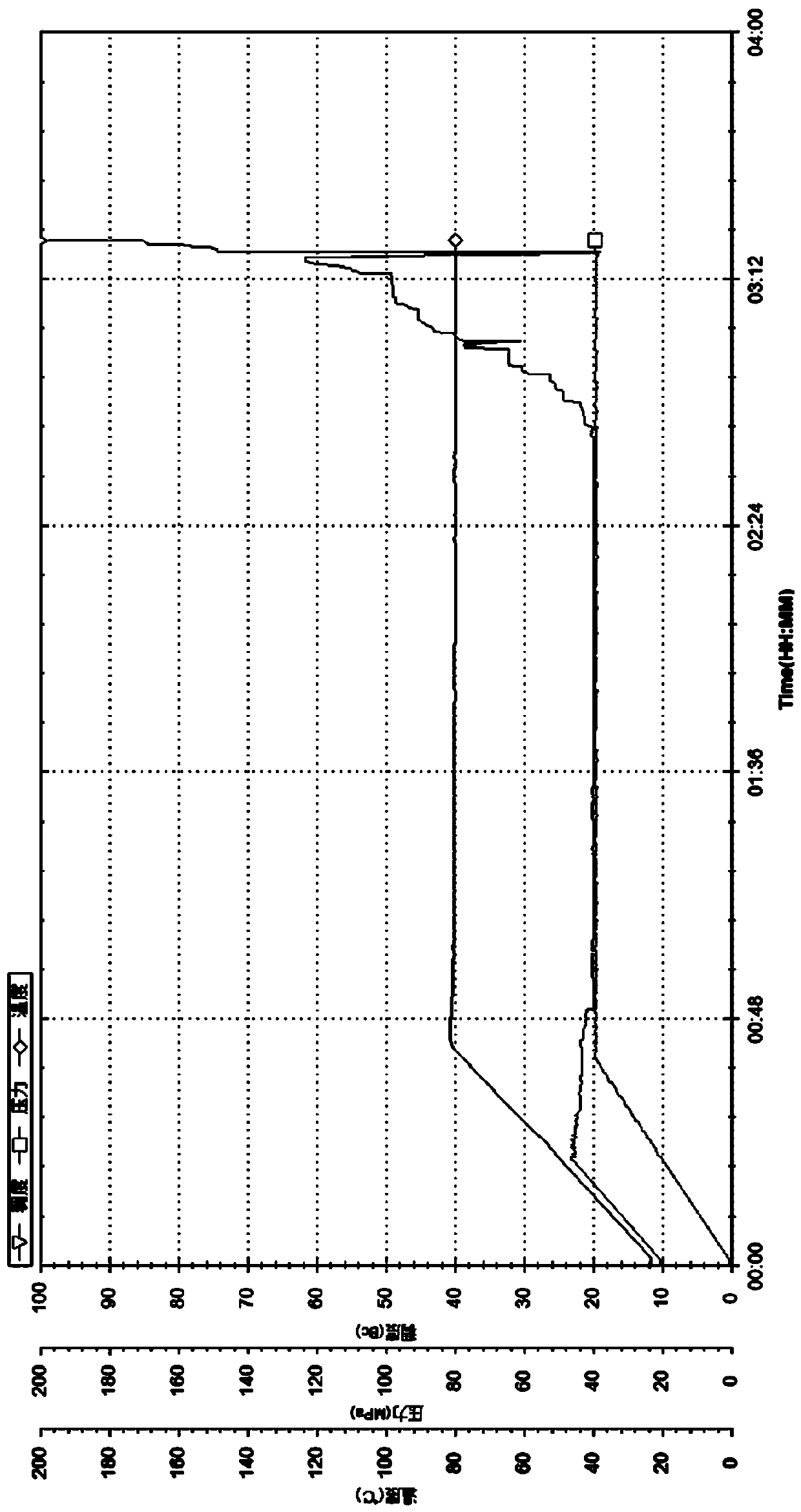

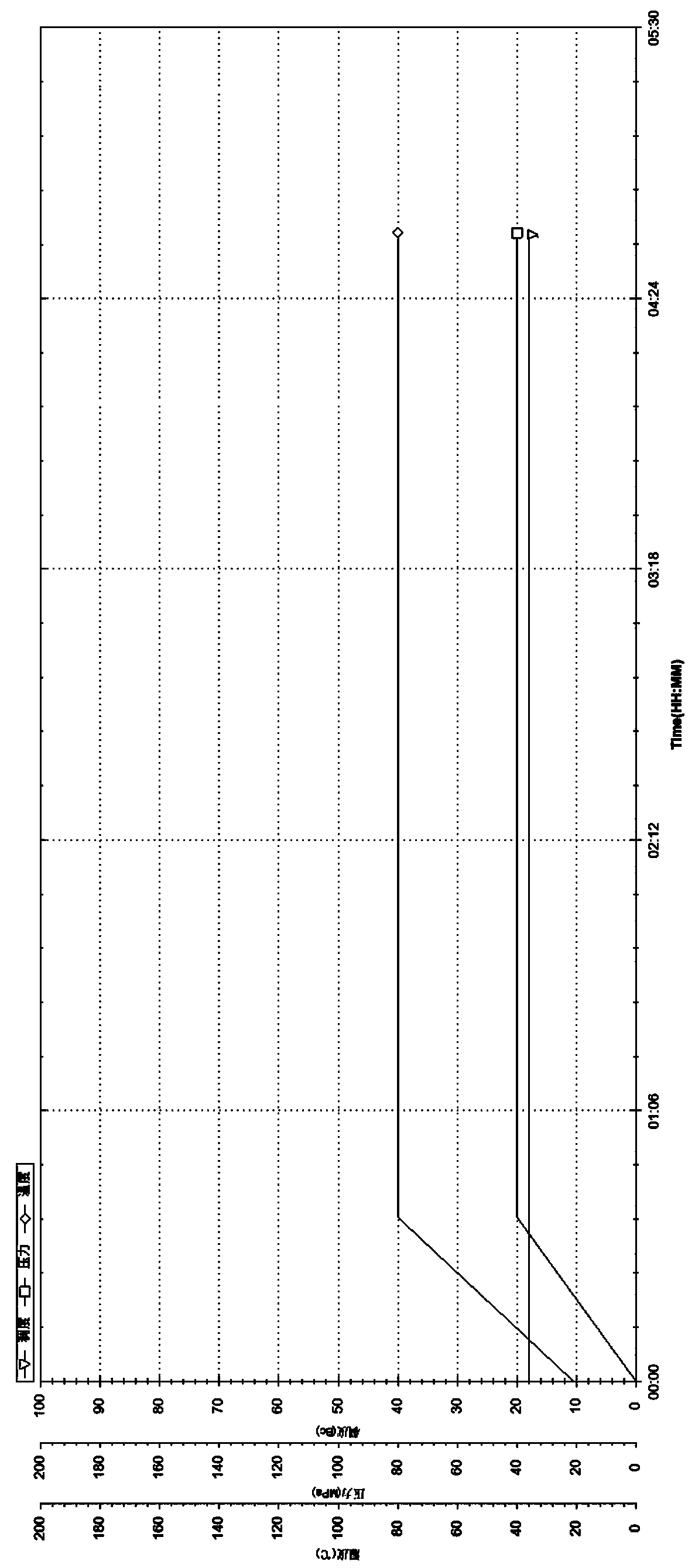

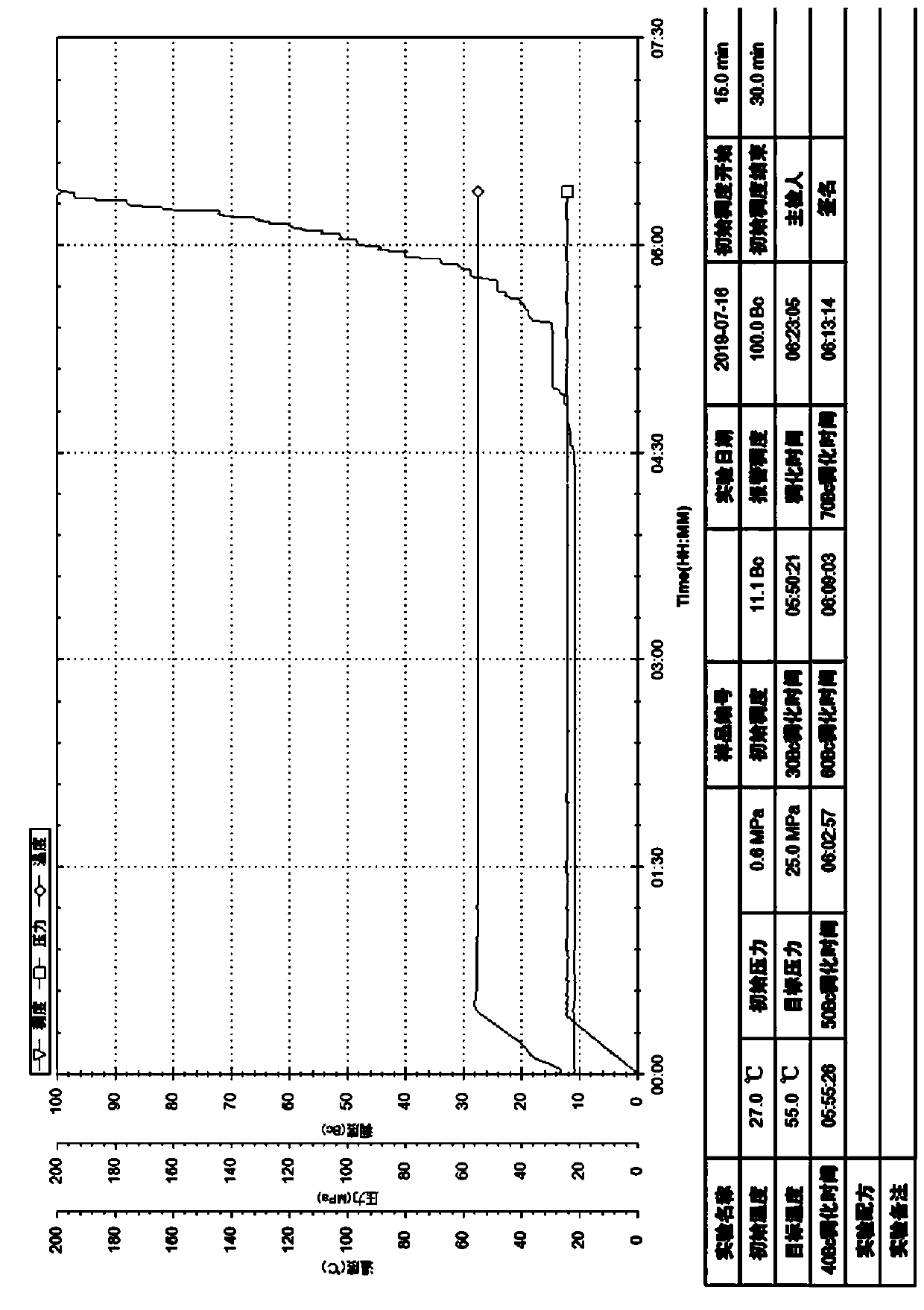

Image

Examples

Embodiment 1

[0044] An embodiment of the long horizontal section horizontal well cementing curable pad fluid of the present invention, the long horizontal section horizontal well cementing curable pad fluid, the long horizontal section horizontal well cementing curable pad fluid consists of the following mass The composition of the serving:

[0045] G grade cement 20-30 parts;

[0046] Closed cell vitrified perlite 20-30 parts;

[0047] 30-40 parts of slag powder;

[0048] Micro silicon 8-12 parts;

[0049] 4-8 parts of plaster of paris;

[0050] 0.6-1.5 parts of sodium sulfate;

[0051] 2-3 parts of quicklime;

[0052] 2-3 parts of slaked lime;

[0053] 2-3 parts of sodium metasilicate;

[0054] 1-2 parts of sodium carbonate;

[0055] Water 95.9-141.8 parts.

[0056] In the above examples, the formulation of the pre-fluid has high solid phase inhibition of mudstone and has a certain ability to prevent leakage and plugging, and can play a good role in isolation and well washing. I...

Embodiment 2

[0065] Furthermore, another embodiment of the curable preflush for cementing long horizontal wells in the present invention further includes an admixture, and the admixture is composed of the following components:

[0066] 2.0-3.5 copies of fluid loss reducer;

[0067] Drag reducer 0.2—0.3 parts;

[0068] Retarder 0.15—0.4 parts;

[0069] Defoamer 0.1-0.3 parts.

[0070] In the above-mentioned embodiment, adopt the comprehensive lightening and stabilizing technology, in order to realize 1.20 g / cm 3 For the following system density, 20%-25% vitrified expanded perlite and 8%-12% micro-silica powder are added to the system, and the selected solid-liquid ratio range is 1.05-1.20; the system depends on Cement, gypsum, and silica fume combine water molecules to stabilize the system. Over time, the underground temperature rises, and the chemical reaction of admixtures activates the binding force between slag, cement, lime and water to maintain system stability.

[0071] The curab...

Embodiment 3

[0073] Combine the following materials:

[0074] G grade cement 25 parts

[0075] Closed cell vitrified perlite 25 parts

[0076] 30 parts of slag powder

[0077] Micro silicon 10 parts

[0078] 5 parts plaster of paris

[0079] 1 part sodium sulfate

[0080] Quicklime 2 parts

[0081] 2 parts slaked lime

[0082] 3 parts sodium metasilicate

[0083] 1 part sodium carbonate

[0084] The above-mentioned solid phase materials are stirred evenly by physical methods, and only need to add different amounts of retarders, fluid loss reducers and drag reducers according to the well temperature and well type, and adjust the thickening time of the system; according to the formation leakage equivalent According to the size, different water-solid ratios within the selected range can be used to form different system densities. Recommended water-solid ratio: 1.07, density: 1.14—1.17g / cm 3 .

[0085] Admixture and water-solid ratio range of use:

[0086] Fluid loss reducer 2.0-3....

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com