Heat treatment method of steel pipe jacking head

A heat treatment method and technology of a heat treatment furnace, applied in the field of heat treatment, can solve the problems that the compactness of the plug protective film is not very high, and the wear resistance and service life of the plug cannot be satisfied, so as to improve the service life, improve the compactness, and improve the wear resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

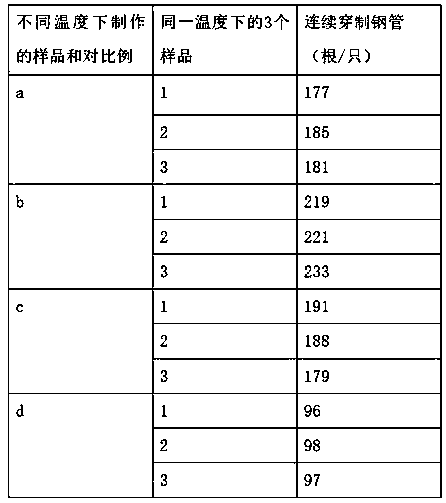

Embodiment 1

[0010] A heat treatment method for a steel pipe plug. After the plug is initially processed and formed, the plug needs to be oxidized on the surface, and the plug is placed in a heat treatment furnace under a wet oxidizing atmosphere formed by an organic liquid and a gas compound. The N2, CO 2 , NH 3 and methanol that enter the furnace are formed by pyrolysis. The feed rate of N 2 is 2 liters / min, the feed rate of CO2 is 2 liters / min, the feed rate of NH 3 is 2 liters / min, methanol Aqueous solution (methanol: water = 0.05: 0.5) feed rate 4cm 3 / min, humidity control at 15%; heating furnace average heating rate 3 ℃ / min, add to 950 ℃ for 3 hours, then cool, the average cooling rate is 6 ℃ / min, when the plug is cooled to 300°C, it will be out of the furnace. After the plug is out of the furnace, a layer of oxide film will be formed on the surface, which is bright in silver color. Because the plug is just formed, the surface needs to be polished, so the surface is machined with ...

Embodiment 2

[0012] A heat treatment method for a steel pipe plug. After the plug is initially processed and formed, the plug needs to be oxidized on the surface, and the plug is placed in a heat treatment furnace under a wet oxidizing atmosphere formed by an organic liquid and a gas compound. The N2, CO2, NH3 and methanol in the furnace are formed by pyrolysis. The feed rate of N2 is 6 liters / min, the feed rate of CO2 is 6 liters / min, and the feed rate of NH3 is 6 liters / min. Methanol: water = 0.05: 0.5) feed rate 5cm 3 / min, humidity control at 15%; heating furnace average temperature rise rate 3 ℃ / min, add to 900 ℃ and keep warm for 4 hours, then cool, the average cooling rate is 6 ℃ / min When the plug is cooled to 300°C, it will be out of the furnace. After the plug is out of the furnace, a layer of oxide film will be formed on the surface, which is bright in silver color. Because the plug is just formed, the surface needs to be polished, so the surface is machined with a processing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com