High-protein alfalfa silage

A technology of silage and alfalfa, applied in animal feed, animal feed, application, etc., can solve the problems of low content of soluble carbohydrates, low content of lactic acid bacteria, and difficult success, etc., and achieve good aerobic stability, aroma, and production simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] 1.1 Test material

[0013] The alfalfa material was planted in the West Lake Management District of Changde City. It was harvested with a combine harvester on July 5, 2019, and crushed to 1-2 cm at the same time. Corn flour is crushed into powder from corn kernels purchased by the Lifang Grain Purchase and Marketing Department of Baxiantong Town, Naiman Banner. Wheat bran is produced by Handan Ruima Noodle Industry Co., Ltd. Corn dried distiller's grains are produced by Mengzhou Houyuan Biotechnology Co., Ltd. Soybean meal was produced by COFCO Cereals and Oils Industry (Jingzhou) Co., Ltd.

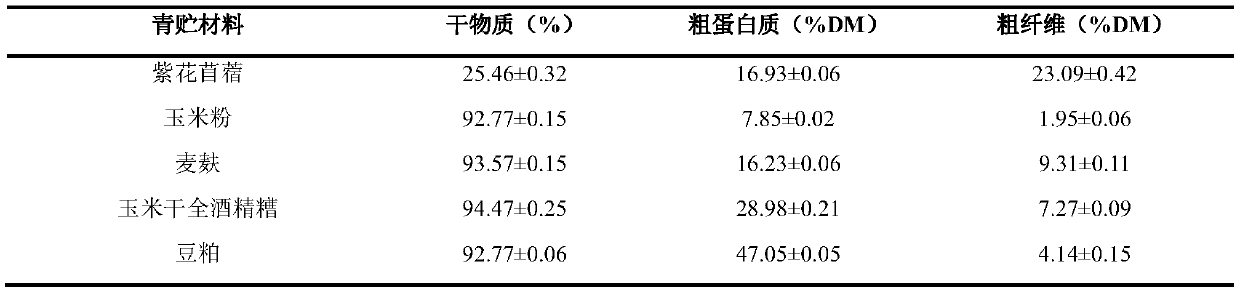

[0014] The nutritional components of various silage raw materials are shown in Table 1.

[0015] Table 1 Nutrient components of silage raw materials

[0016]

[0017] Note: Data are presented as "mean ± standard deviation". The same below.

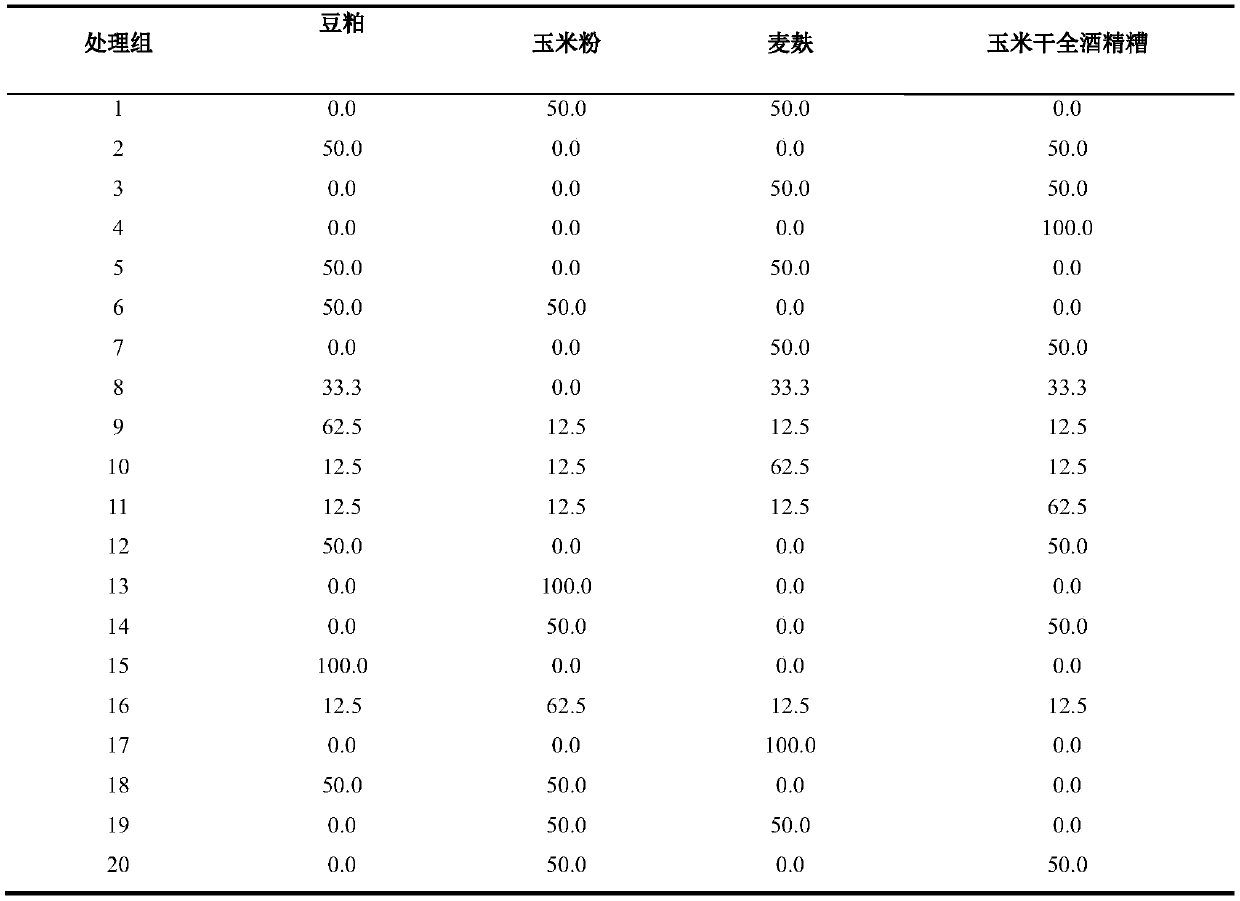

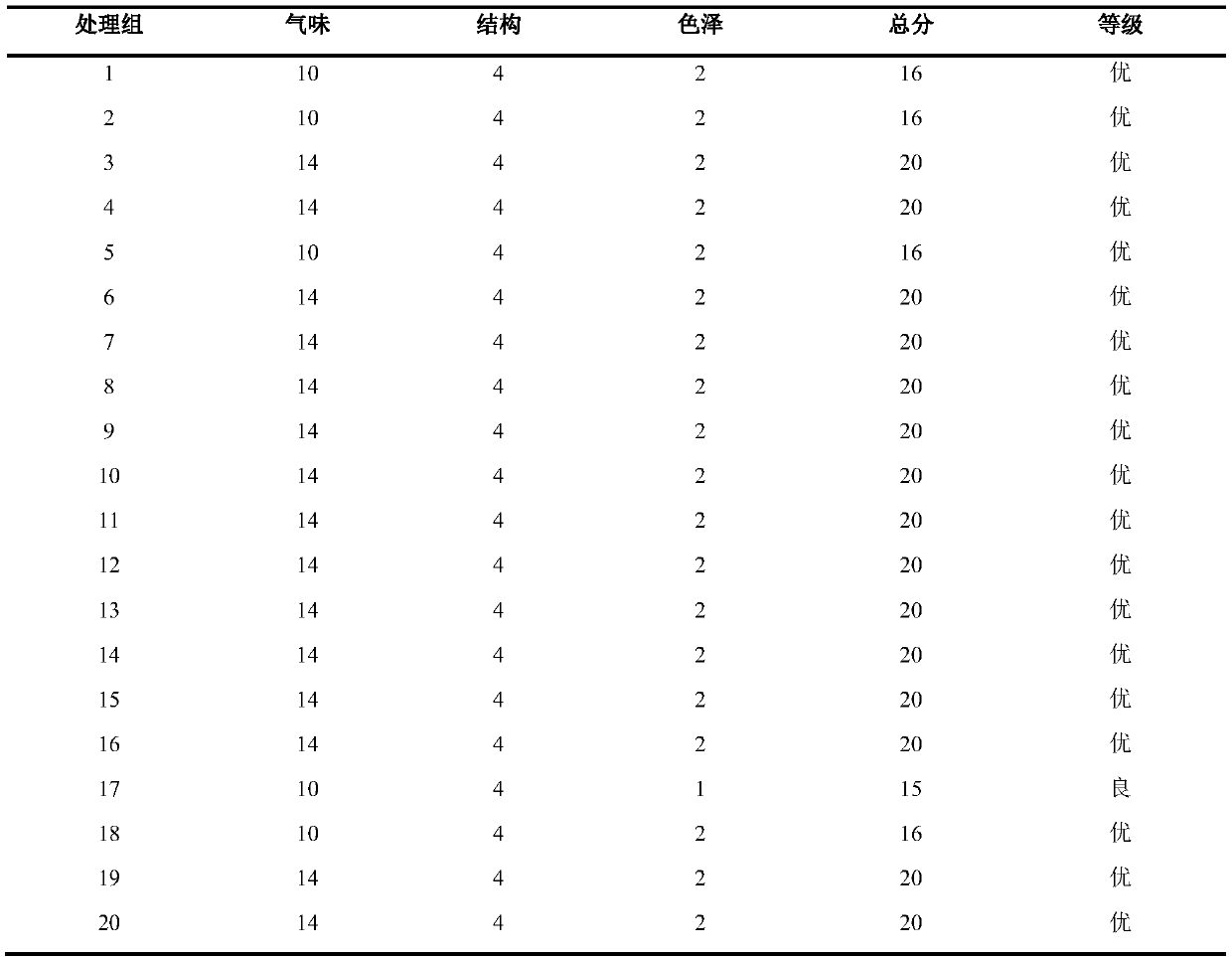

[0018] 1.2 Experimental design and production of silage

[0019] This experiment intends to use the Optimal method in the mixture de...

Embodiment 2

[0055] In order to verify the effect of the alfalfa high-protein silage provided by the application for feeding pigs, 45 pigs in good health were selected, and the feeding test was started 45 days before slaughter. A completely randomized experimental design was adopted, and 45 pigs were randomly divided into 3 groups (n=15), and divided into two experimental groups, control group A and B; Protein silage (80% alfalfa, 10-12.5% soybean meal, 0-2.5% corn meal, 0-2.5% wheat bran, and 2.5-10% corn distiller's grain) replaced 10% of the complete diet. The silage and the full-price ration are mixed according to the ratio, and a small amount of water is added to maintain the fluidity of the feed, and they are fed in the form of liquid feed.

[0056] The group house feeding method is adopted, and the pig house is thoroughly cleaned and disinfected before feeding. After one week of pre-feeding, the formal feeding test was carried out. The test period is 45d.

[0057] The results s...

Embodiment 3

[0059] In order to verify the effect of the alfalfa high-protein silage provided by the application for feeding perinatal sows, 45 perinatal sows in good health were selected to start a feeding experiment. A completely randomized experimental design was adopted, and 45 perinatal sows were randomly divided into 3 groups (n=15), and divided into two experimental groups, control group A and B; Alfalfa high-protein silage (80% alfalfa, 10-12.5% soybean meal, 0-2.5% corn meal, 0-2.5% wheat bran and 2.5-10% corn dry distiller's grain) replaces 20% of the full-price diet . The silage and the full-price ration are mixed according to the ratio, and a small amount of water is added to maintain the fluidity of the feed, and they are fed in the form of liquid feed.

[0060] The group house feeding method is adopted, and the pig house is thoroughly cleaned and disinfected before feeding. After one week of pre-feeding, the formal feeding test was carried out. The test period is the who...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com